Color electronic paper display module and manufacturing method thereof

A display module and manufacturing method technology, applied in the directions of light guides, optics, instruments, etc., can solve the problems of high product thickness and many processes, and achieve the effects of simplified structure, thin thickness and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

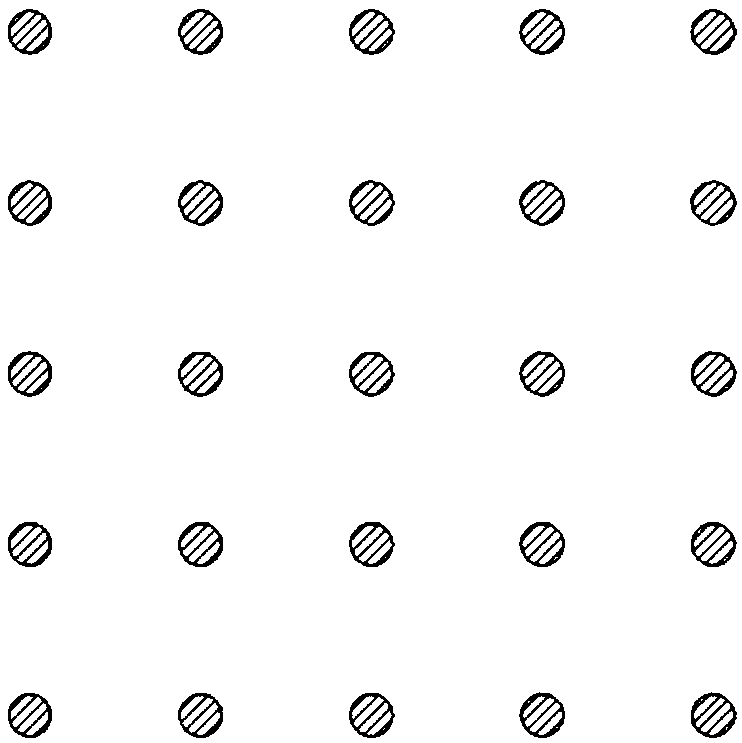

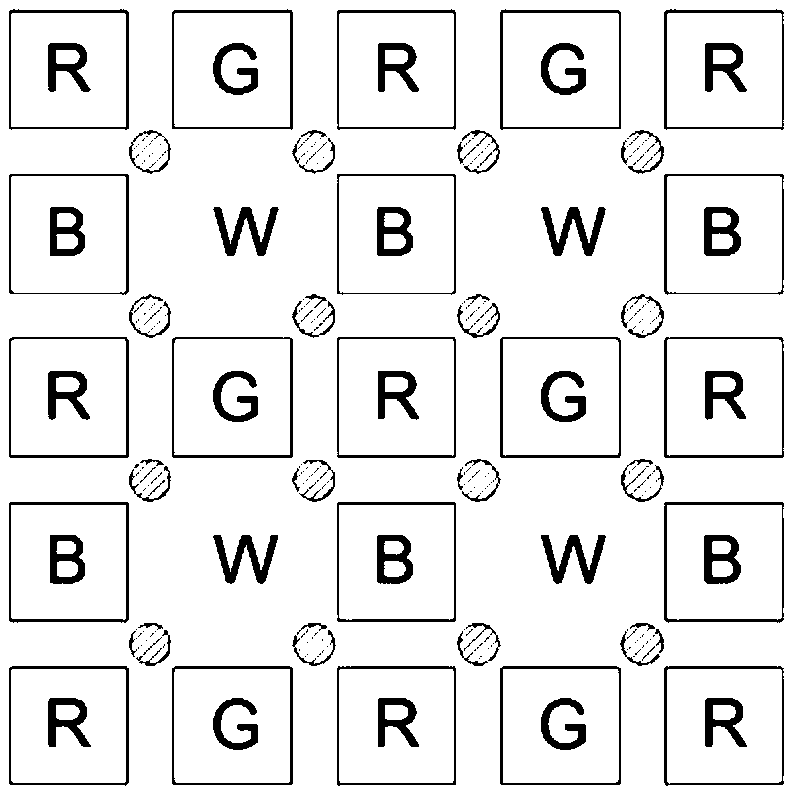

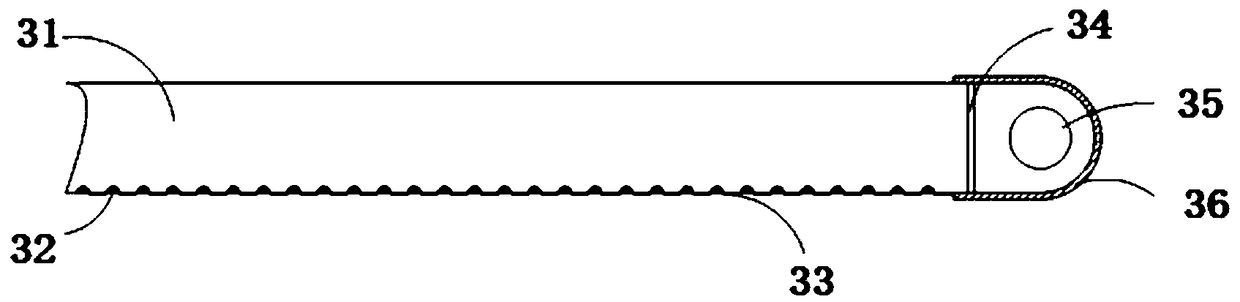

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Since the electronic paper itself does not emit light, a front light component will be added to the module, so that the display module can meet the requirements of all-weather use. However, due to the way that the filter layer is made separately in the past, the structure is complicated and the overall thickness is relatively thick; the front light assembly of the present invention consists of a light source assembly and a light guide plate with a color filter function. Fabricate RGB and transparent four-color filter structures on the acrylic film with the yellow light process, and then set the diffusion points in the form of laser array dots to complete the production of the light guide plate; the array diffusion point diagram of the ordinary light guide plate, such as figure 1 Shown; The light guide plate with filter function of the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap