Electric power material prefabrication and distribution method based on electronic order mode

A technology for power materials and electronic orders, applied in resources, logistics, instruments, etc., can solve problems such as low work efficiency, waste of resources in power companies, and poor timeliness, and achieve the effects of avoiding construction delays, shortening power outages, and speeding up turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

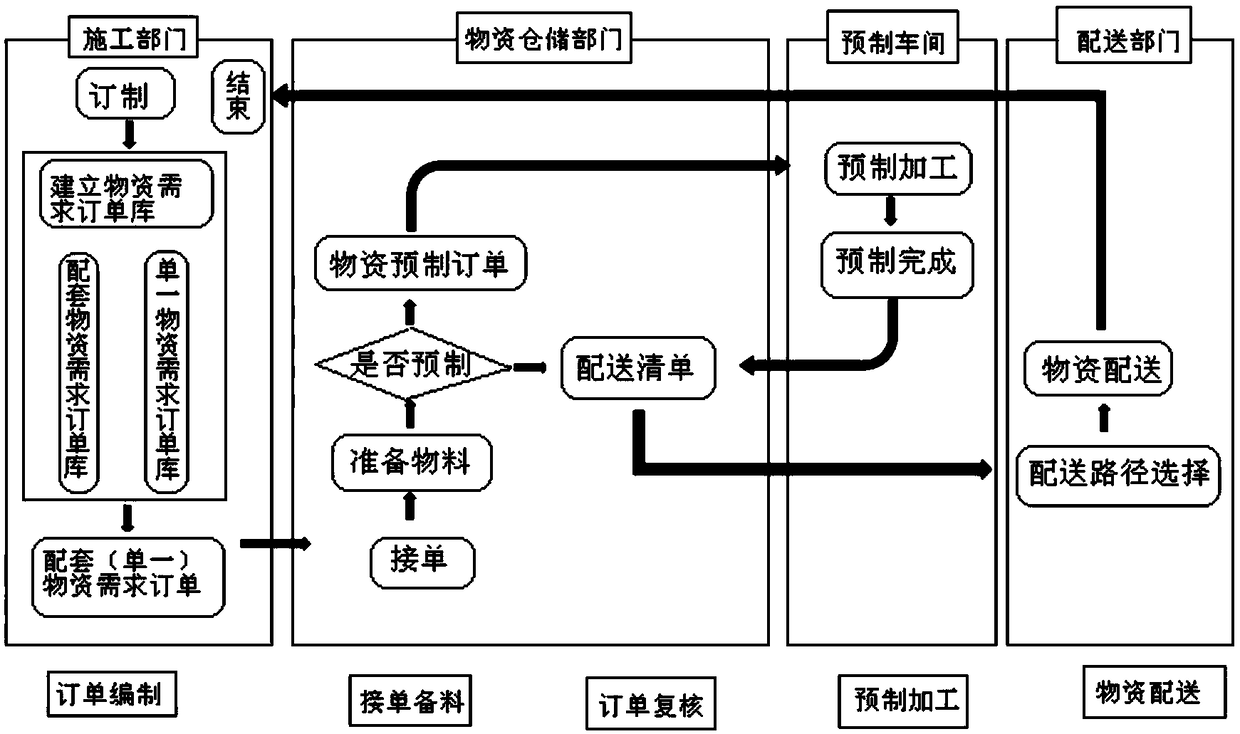

[0026] As shown in the figure, the electric power material prefabrication and distribution method based on the electronic order mode includes the following steps:

[0027] Step 1. First, establish a material demand order library in the designed order APP, and the material demand order library includes a supporting material demand order library and a single material demand order library;

[0028] Step 2. The construction department uses the order APP to select a typical design supporting material demand order or a single material demand order according to the material demand plan of the business expansion report and installation and emergency repair project, and initiates the order, the material storage department receives the order, and the order is transferred to the material branch. Central material warehousing department and distribution department.

[0029] Step 3. The material storage department organizes the corresponding materials according to the above order requiremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com