Method for connecting metal electrode of solar cell with photovoltaic welding strip

A technology for solar cells and metal electrodes, which is applied in the field of solar cells, can solve the problems of difficult connection between the metal poles and wires of solar cells, low connection resistance, etc., and achieves the effects of low cost, small connection resistance and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

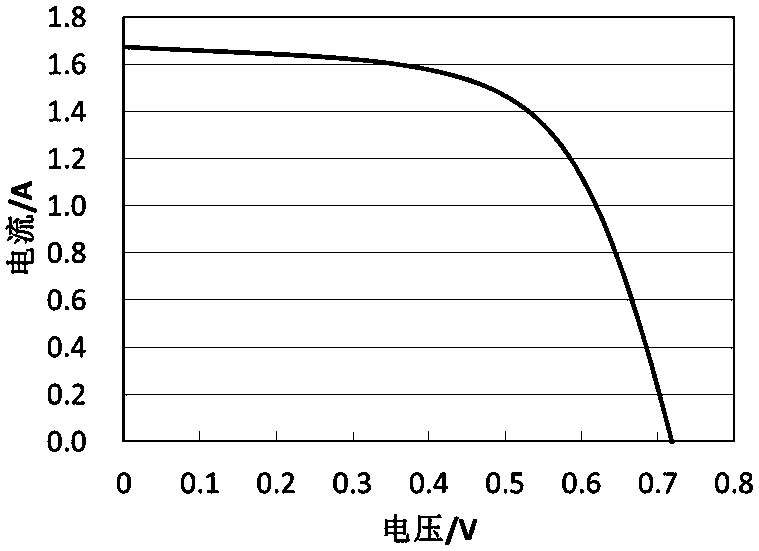

Embodiment 1)

[0035] First, the Anisotropic Conductive Film (ACF) is attached to the metal electrode of the solar cell by using a thermal compression lamination equipment. Among them, the width of the ACF adhesive film is 1.2 mm, the thickness is 20 μm, and the feeding length is 117 mm; the hot-pressing temperature is 140 ° C, and the time is 10 s.

[0036] Then, attach a photovoltaic ribbon (tin-coated copper ribbon in this embodiment) with a length of 150 mm, a width of 1.6 mm, and a thickness of 0.25 mm on the above-mentioned ACF adhesive film. Subsequently, the solar cell with the ACF and the photovoltaic ribbon attached was placed in a hot-press laminating equipment for hot-press bonding. The hot-press temperature was 160° C. and the hot-press time was 30 s.

[0037] Then, solder the photovoltaic ribbon soaked in flux to the silver wire printed on the FTO of the battery with an electric soldering iron. In the above-mentioned solar cells, the tinned copper strip bonded by ACF and titaniu...

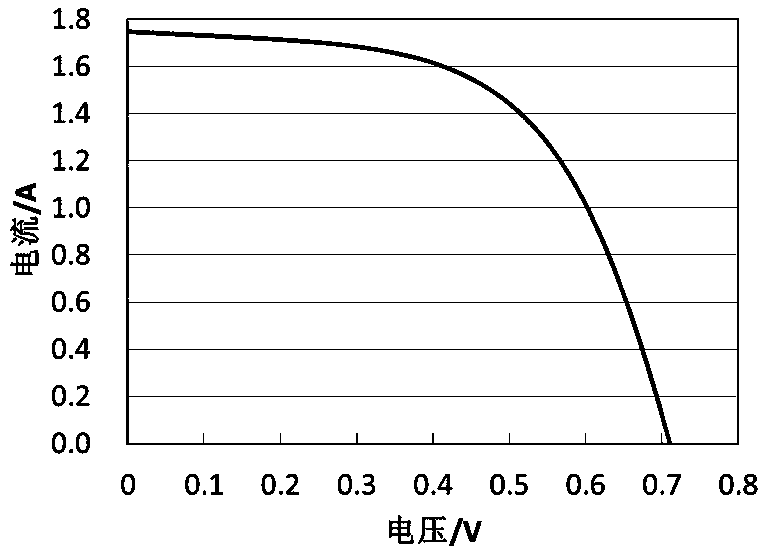

Embodiment 2)

[0040] First, the Anisotropic Conductive Film (ACF) is attached to the metal electrode of the solar cell by using a thermal compression lamination equipment. Among them, the width of the ACF film is 1.0 mm, the thickness is 20 μm, and the feeding length is 117 mm; the hot-pressing temperature is 140 ° C, and the time is 10 s.

[0041] Then, attach a photovoltaic ribbon (tin-coated copper ribbon in this embodiment) with a length of 150 mm, a width of 1.6 mm, and a thickness of 0.25 mm on the above-mentioned ACF adhesive film. Subsequently, the solar cell with the ACF and the photovoltaic ribbon attached was placed in a hot-press laminating equipment for hot-press bonding. The hot-press temperature was 190° C. and the hot-press time was 10 s.

[0042] Then, solder the photovoltaic ribbon soaked in flux to the silver wire printed on the FTO of the battery with an electric soldering iron. In the above battery, the tinned copper strip bonded by ACF and titanium foil is the positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com