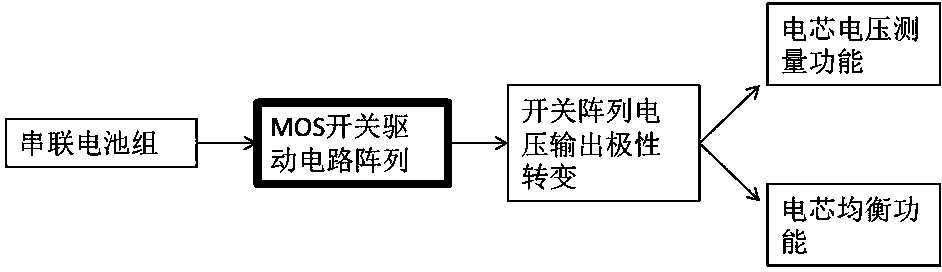

MOS switch drive circuit for series battery pack battery management system and array thereof

A switch drive circuit and battery management system technology, applied in electronic switches, circuits, secondary batteries, etc., can solve the problems of high chip price, complex structure, and high price, so as to improve system reliability and simplify drive circuit structure , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-M

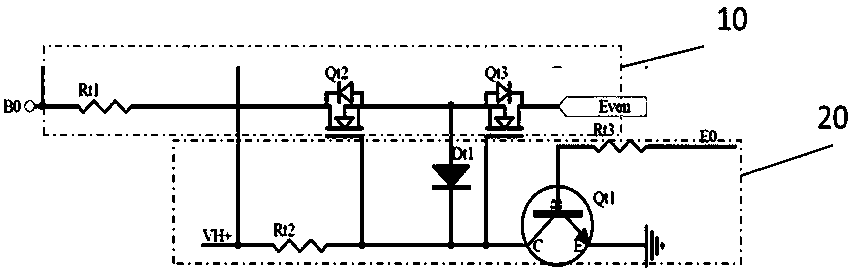

[0030] Embodiment 1-MOS switch driving circuit:

[0031] In this embodiment, Qt2 and Qt3 are NMOS transistors with a withstand voltage of 100v and a rated current of 2A, which are used in series battery packs below 100v. The battery pack voltage and battery cell balance require current. The high-voltage power supply VH+ is 200V, which is provided by a high-voltage pump twice the voltage of the battery pack. Here VH+ can also be provided by a high-voltage charge pump or other high-voltage power sources, and its potential must be higher than that of the positive electrode of the battery pack. The MOS gate charging resistor Rt2 (1 megohm) is connected to the high voltage power supply VH+. The gate clamping diode Dt1 is a 10V zener diode, and its regulated voltage value is greater than the MOS turn-on threshold voltage and lower than the maximum withstand voltage of the gate. The triode Qt1 is an npn tube with a withstand voltage of 300v and a rated current of 0.5A. Its withsta...

Embodiment 2

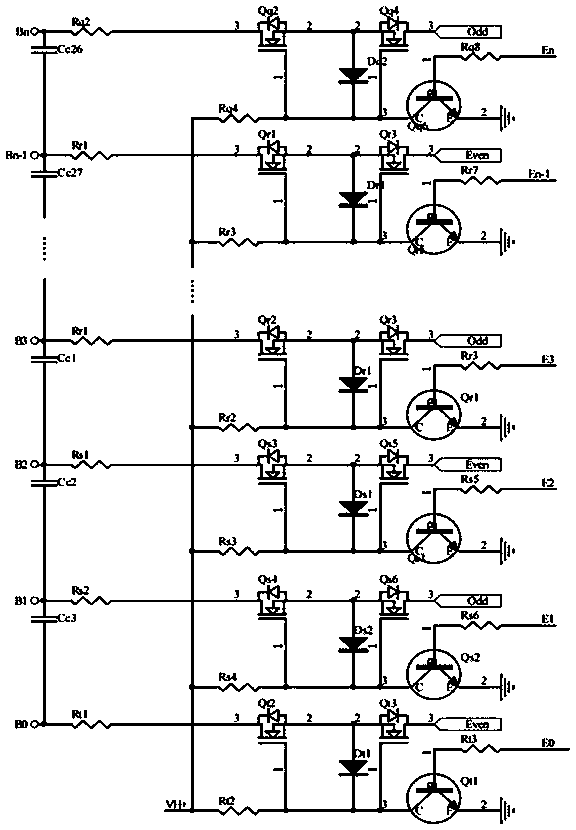

[0033] Embodiment 2-MOS switch driving circuit array:

[0034] In this embodiment, a series battery pack of 21 cells is connected. There are 22 circuits of Embodiment 1 to form an array. The negative pole of battery cell 1 is marked as B0, the positive pole of battery cell 1 is also the negative pole of battery cell 2, marked as B1, and so on, the negative pole of battery cell 21 is marked as B20, and the positive pole of battery cell 21 is marked as B21. When the mark number is 0 or an even number, it is connected to the output node Even, and when the mark number is odd, it is connected to the output node Odd. It is known that the fully charged voltage of each cell of the series battery pack is 4.2V, and the charged voltage of the entire series battery pack is 88.2V, so it is very suitable to select an NMOS with a withstand voltage of 100V in the circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com