White tea and processing method thereof

A processing method and technology of white tea, applied in tea treatment before extraction, etc., can solve the problems of poor persistence of high-flavor characteristics, unfavorable product preservation, and short use time, so as to improve the aroma quality of white tea, facilitate parameter adjustment and control, and shorten the use time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

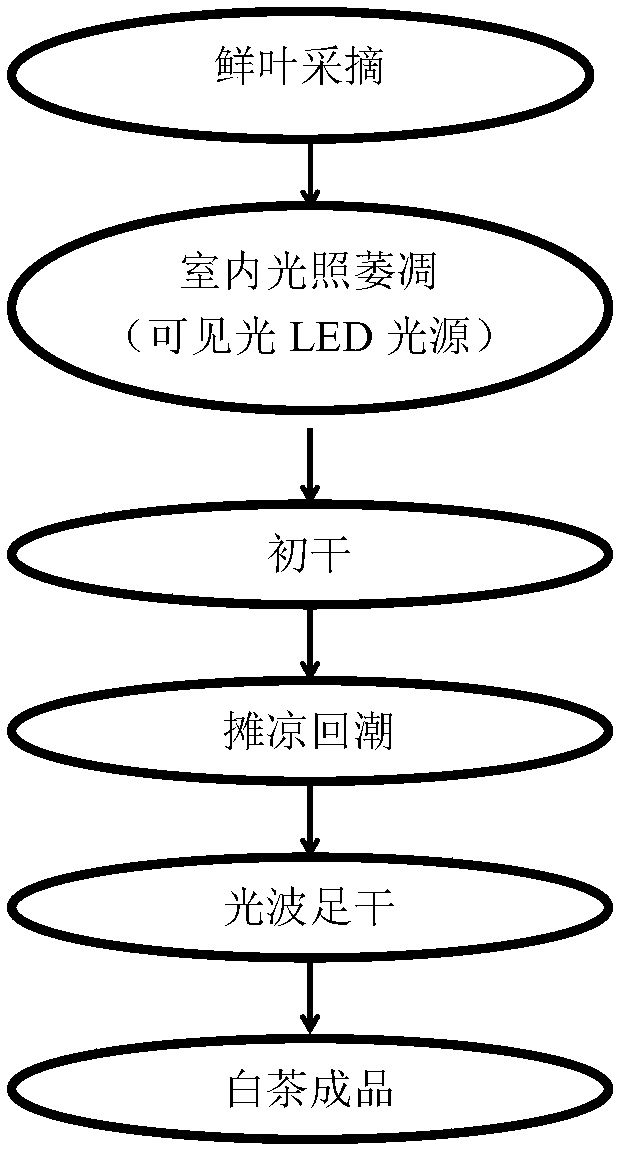

[0052] Embodiment 1, white tea processing method, select " Chunyu No. 2 " as raw material, and its step is as follows (as figure 1 shown):

[0053] (1) Picking fresh leaves: picking fresh leaves with one bud and one leaf at the beginning to one bud and two leaves at the beginning;

[0054] The mechanical composition of fresh leaves is: single bud 1.2%, one bud and one leaf 75.2%, one bud and two leaves 21.1%, one bud with three leaves and above 0.5%, single leaf 2.0%.

[0055] The above-mentioned % is mass %.

[0056] The picking time is generally 7:00-11:00 in the morning and 3:00-6:00 in the afternoon. It is necessary to avoid extrusion and collision during picking and transportation. After the fresh leaves are transported to the tea factory, they should be spread in the withering tank in time to dissipate the accumulated heat. The fresh leaves need to be sorted after entering the factory, and the fresh leaves of different picking times and the fresh leaves of different m...

Embodiment 2

[0090] Embodiment 2, white tea processing method, select " Chunyu No. 1 " as raw material, and its steps are as follows:

[0091] (1) Picking fresh leaves: picking fresh leaves with one bud and one leaf at the beginning to one bud and two leaves at the beginning;

[0092] The mechanical composition of fresh leaves is: 0.14% for single bud, 26.30% for one bud and one leaf, 67.62% for one bud and two leaves, 2.92% for one bud and three leaves, and 3.02% for single leaf.

[0093] (2), withering: the present embodiment adopts the mode of intermittent artificial light source (cooperating with temperature control) to carry out withering, and this artificial light source is the visible light LED light source of 70% red-orange light+20% blue-violet light+10% yellow-green light, concrete steps are as follows:

[0094] Evenly spread the fresh leaves picked in step (1) into the withering tank, the thickness of the fresh leaves is 3.0cm, and the visible light LED light source is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com