Intermittent microwave baking method for marinated eggs

An intermittent, microwave technology, applied in the field of marinated egg baking, can solve the problems of large difference in water content inside and outside, uneven color, skin shrinkage, etc., and achieve the effect of short time consumption, uniform color, complete and smooth skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

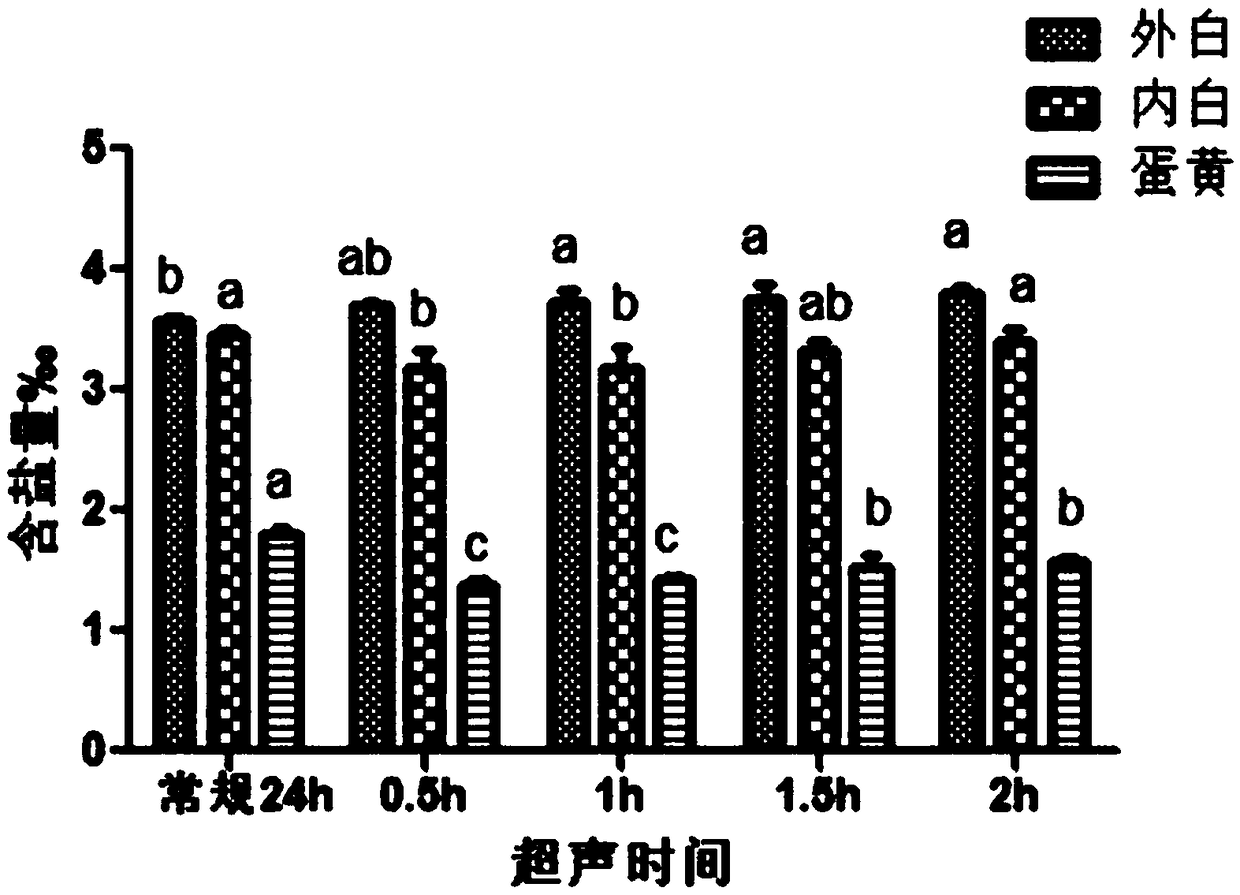

[0048] 1.2.1 Sample preparation

[0049] Selection and cleaning of raw eggs (weight 60g±2g, Haval index>0.38)→precooking (100°C, 10min)→chilling, cracking shell (room temperature, 5min)→boiling (100°C, 2h)→marinating ( Ultrasonic marinating) → packaging, sterilization (121°C, 15min)

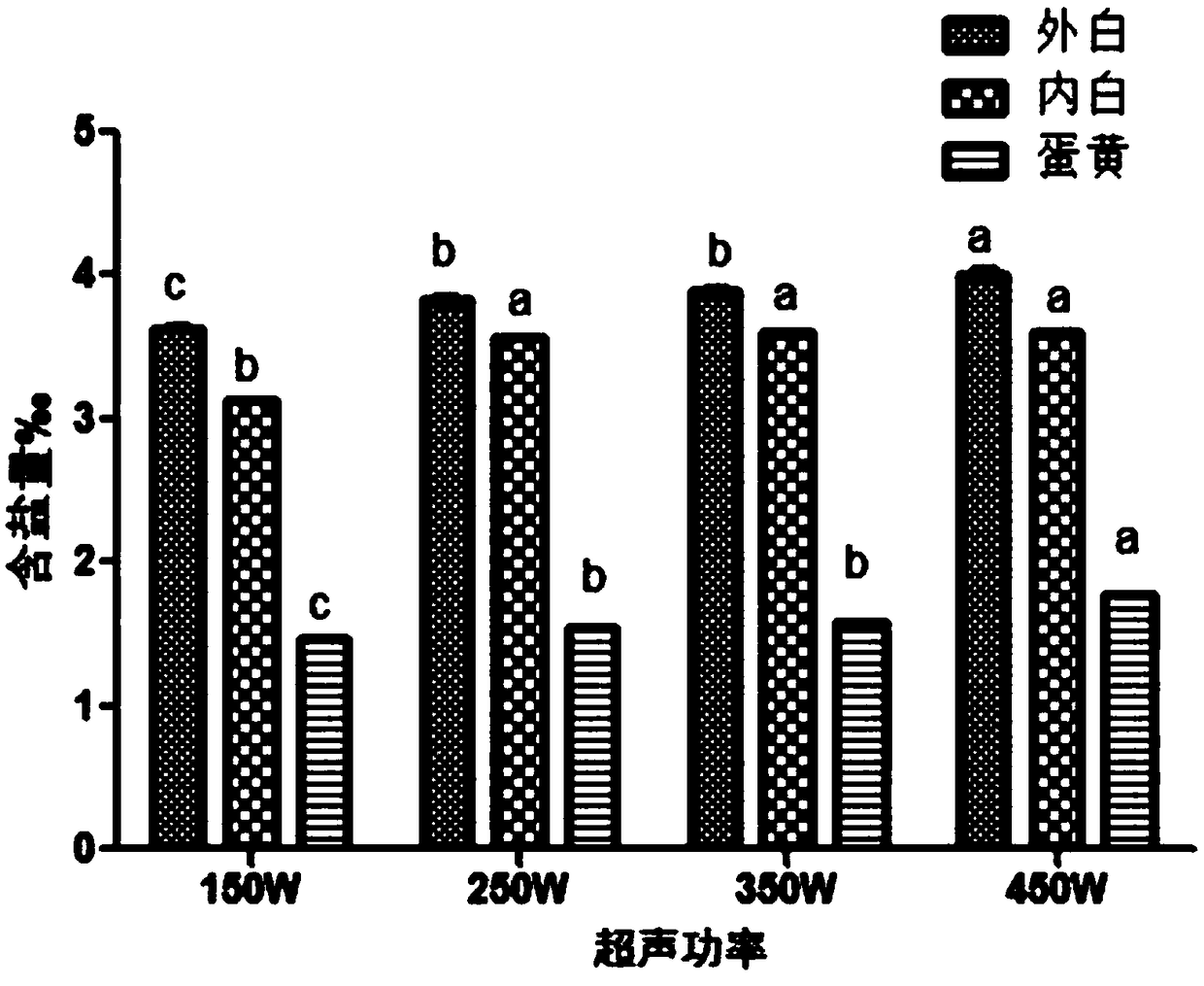

[0050] 1.2.2 Single factor optimization of ultrasonic power

[0051] Divide the above-mentioned fresh eggs into 4 groups, 15 eggs in each group, and process the samples according to the method in 1.2.1. Ultrasonic parameters are set to ultrasonic frequency 40kHz, ultrasonic pickling time 2h, ultrasonic power is set to 150W, 250W, 350W, 450W respectively.

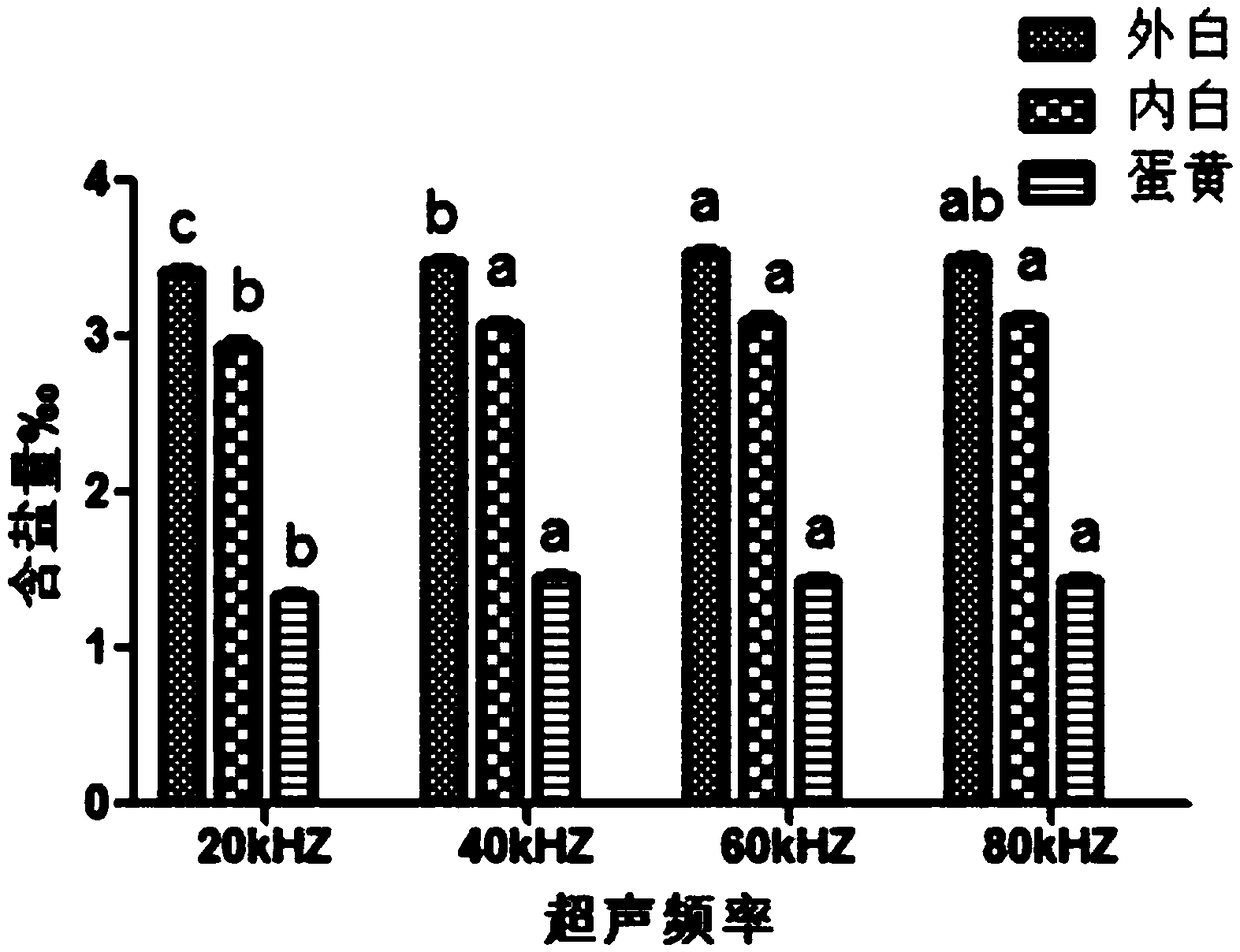

[0052] 1.2.3 Single factor optimization of ultrasonic frequency

[0053] Divide the above-mentioned fresh eggs into 4 groups, 15 eggs in each group, and process the samples according to the method in 1.2.1. The ultrasonic pickling time is set to 2h in the ultrasonic parameters, the ultrasonic power is selected according to the results in 1....

Embodiment 1

[0102]Clean the fresh eggs, then boil them for 10 minutes, take them out and put them in cold water to cool down quickly, then remove the shells; put the shelled eggs into the brine according to the weight ratio of 1:1.5, first boil them on high heat and then marinate them on low heat for 2 hours; Then marinate it under the condition of ultrasonic power 400W and ultrasonic frequency 60kHZ for 1.5h; finally bake it under the conditions of microwave power 100W, microwave time 30s, and microwave times 3 times to obtain the product. in,

Embodiment 2

[0104] Clean the fresh eggs, then boil them for 10 minutes, take them out and put them in cold water to cool down quickly, then remove the shells; put the shelled eggs into the brine according to the weight ratio of 1:1.5, first boil them on high heat and then marinate them on low heat for 2 hours; Then it is marinated for 1.5h under the ultrasonic power of 400W and ultrasonic frequency of 60kHZ; finally, it is baked under the conditions of microwave power of 300W, microwave time of 30s, and microwave times of 3 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com