Wet concrete recovery system based on Internet of Things, wet concrete recovery method, and wet concrete recovery managing and controlling method

A recovery system and concrete technology, applied in the field of concrete mixing, can solve the problems that the equipment status cannot be diagnosed, analyzed, maintained and controlled in time, the user cannot provide real-time query, data analysis equipment monitoring, equipment dynamics cannot be timely and accurately grasped, etc., to achieve good management and control , to achieve integration and prevent overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below through specific embodiments.

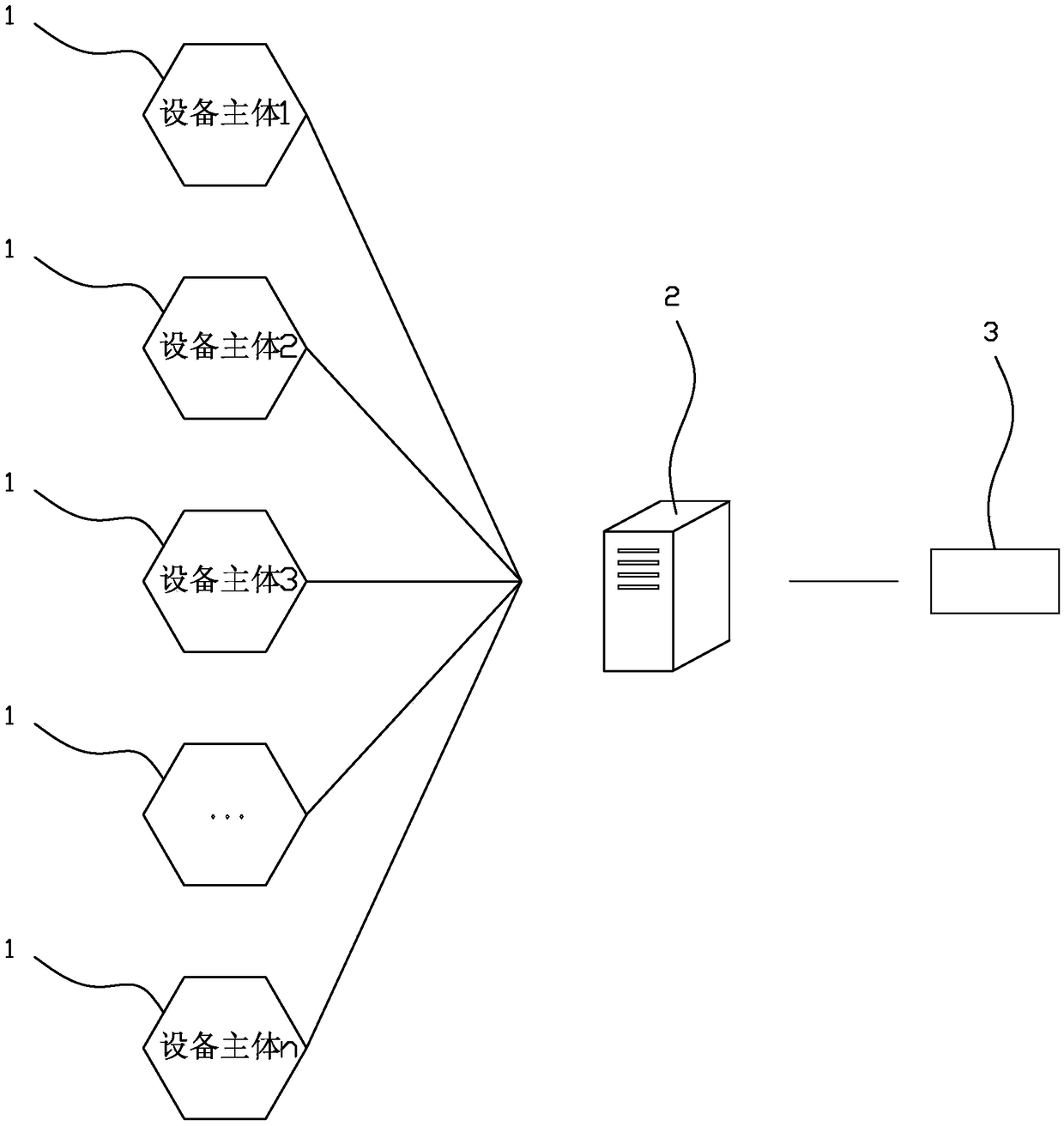

[0036] refer to Figure 1 to Figure 3 , a wet concrete recycling system based on the Internet of Things of the present invention includes a device main body 1, a data collection system for collecting information on each device, a cloud server 2 and a user terminal 3.

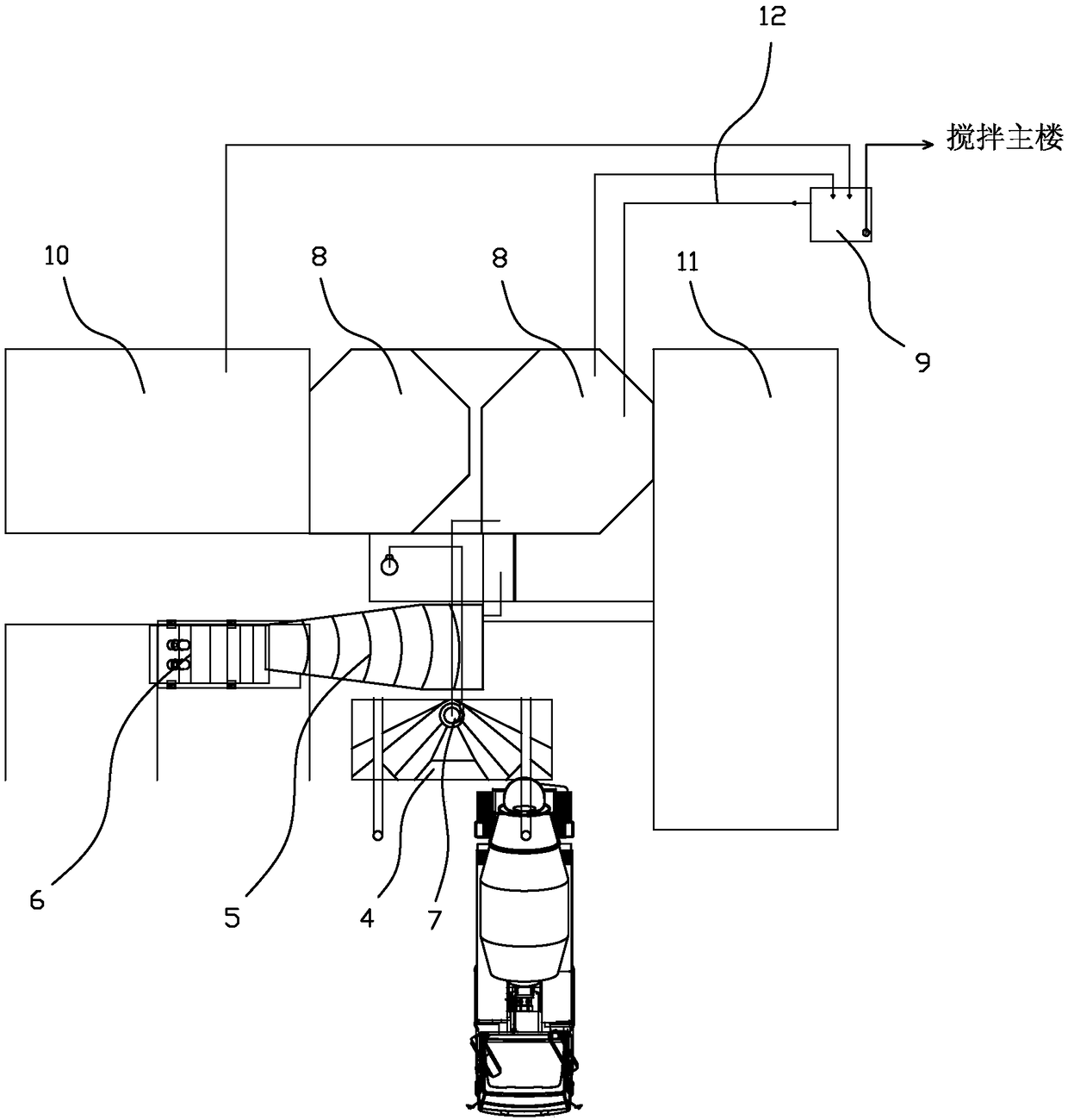

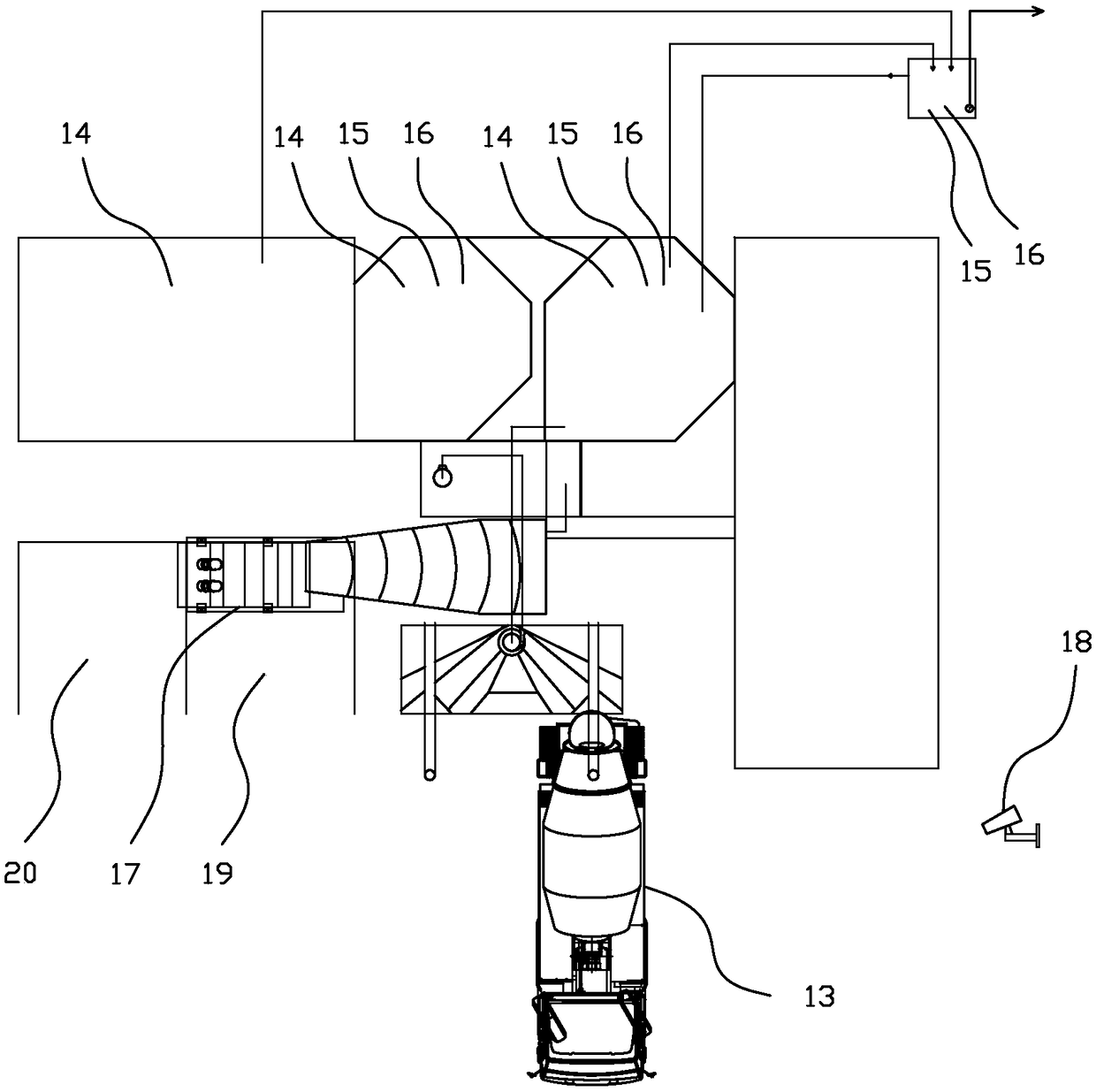

[0037] Equipment main body 1, including car washing system 4, wet concrete recovery machine 5, sand and gravel separation vibrating screen 6, cyclone separation system 7, mixing tank 8, mud water concentration adjustment tank 9, clear water tank 10, standby sedimentation tank 11 and control system The wet concrete recycling machine 5 is used to separate sand and gravel and muddy water, and its feed port is connected to the cleaning object discharge port of the car washing system 4; The feed port is installed under the sand and gravel discharge port of the wet concrete recovery machine 5; the cyclone separation system 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com