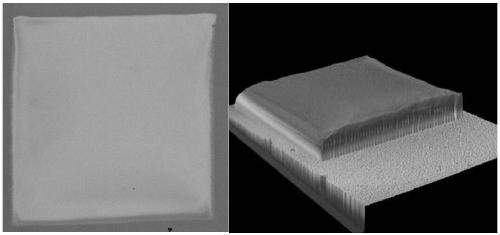

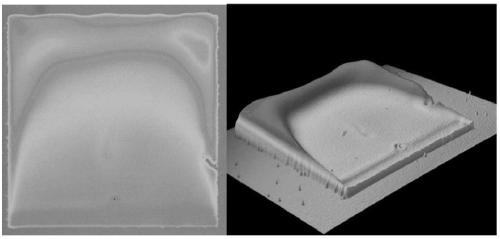

Method for improving ink deposition uniformity of inkjet printing

An inkjet printing and uniformity technology, applied in printing, ink, household utensils, etc., can solve the problems that affect the uniformity of the final graphics, slow-drying ink can not meet the process requirements, etc., to shorten the printing time and reduce the overall level , to solve the effect of uneven deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. Drug and reagent preparation

[0016] Preparation of raw materials for solution preparation: zirconium oxychloride octahydrate, analytically pure, content ≥ 99.0%; polyvinylpyrrolidone, K30; ethylene glycol; ethylene glycol methyl ether.

[0017] 2. Substrate and container cleaning

[0018] Finger bottle cleaning: Unscrew the bottle cap of the finger bottle to be washed, sink it into a large beaker filled with isopropanol, and put the bottle cap together. The bottle is completely filled with isopropanol without air bubbles, and then Ultrasonic vibration for 10 to 30 minutes, and then change to deionized water and the same ultrasonic vibration for 10 to 30 minutes. When using tweezers to transfer the bottle, avoid contacting the inner wall of the bottle with the tweezers. After cleaning, put the bottle in the oven to dry.

[0019] Magnetic rotor cleaning: Put the magnetic rotor to be washed into a beaker containing isopropanol, tetrahydrofuran, alkaline washing sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com