On-line monitoring system and method for waste viscose liquid

A monitoring system and waste liquid technology, applied in the field of on-line monitoring system of viscose waste liquid, can solve problems such as unfavorable recovery efficiency, long recovery time, waste of resources, etc., to reduce workload, improve time and efficiency, and prevent clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

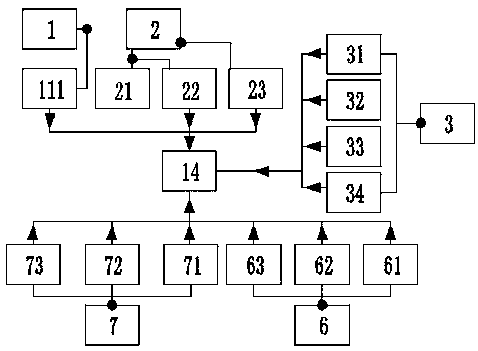

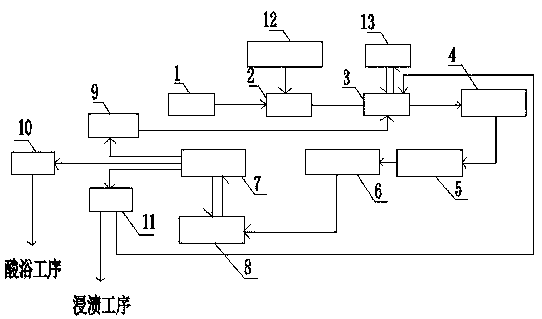

[0033] Such as figure 1As shown, an on-line monitoring system for viscose waste liquid includes a general controller 14 and a centrifuge 1, a transfer tank 2, a blending tank 3, a resin tower 6 and a bipolar membrane device 7 connected in sequence, and the centrifuge 1 The outlet of the transfer tank 2 is connected to an electromagnetic flowmeter A111, the inlet of the transfer tank 2 is connected to a desalinated water tank 21, and an electromagnetic flow meter B22 is installed between the desalinated water tank 21 and the transfer tank 2, and the desalinated water tank 21 is installed with Conductivity meter A23, temperature sensor A31, ph meter A32, electromagnetic flowmeter C33 and conductivity meter B34 are arranged in the described blending tank 3, conductivity meter C61, ph meter B62 and electromagnetic flow meter are installed in the resin tower 6 Meter D (63), the temperature sensor B71, Hall sensor 72 and voltage transformer (73) are installed in the bipolar membrane...

Embodiment 2

[0036] Such as figure 1 As shown, an on-line monitoring system for viscose waste liquid includes a general controller 14 and a centrifuge 1, a transfer tank 2, a blending tank 3, a resin tower 6 and a bipolar membrane device 7 connected in sequence, and the centrifuge 1 The outlet of the transfer tank 2 is connected to an electromagnetic flowmeter A111, the inlet of the transfer tank 2 is connected to a desalinated water tank 21, and an electromagnetic flow meter B22 is installed between the desalinated water tank 21 and the transfer tank 2, and the desalinated water tank 21 is installed with Conductivity meter A23, temperature sensor A31, ph meter A32, electromagnetic flowmeter C33 and conductivity meter B34 are arranged in the described blending tank 3, conductivity meter C61, ph meter B62 and electromagnetic flow meter are installed in the resin tower 6 Meter D (63), the temperature sensor B71, Hall sensor 72 and voltage transformer (73) are installed in the bipolar membran...

Embodiment 3

[0043] Such as figure 1 As shown, an on-line monitoring system for viscose waste liquid includes a general controller 14 and a centrifuge 1, a transfer tank 2, a blending tank 3, a resin tower 6 and a bipolar membrane device 7 connected in sequence, and the centrifuge 1 The outlet of the transfer tank 2 is connected to an electromagnetic flowmeter A111, the inlet of the transfer tank 2 is connected to a desalinated water tank 21, and an electromagnetic flow meter B22 is installed between the desalinated water tank 21 and the transfer tank 2, and the desalinated water tank 21 is installed with Conductivity meter A23, temperature sensor A31, ph meter A32, electromagnetic flowmeter C33 and conductivity meter B34 are arranged in the described blending tank 3, conductivity meter C61, ph meter B62 and electromagnetic flow meter are installed in the resin tower 6 Meter D (63), the temperature sensor B71, Hall sensor 72 and voltage transformer (73) are installed in the bipolar membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com