Preparation method of hyperbranched paraffin and application of hyperbranched paraffin in artificial boards

A technology of wood-based panels and hyperbranched polymers, which is applied in the field of wood-based panels, can solve the problems of poor waterproofness of wood-based panels, and achieve the effect of improving unstable waterproof effects, long-lasting effects, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

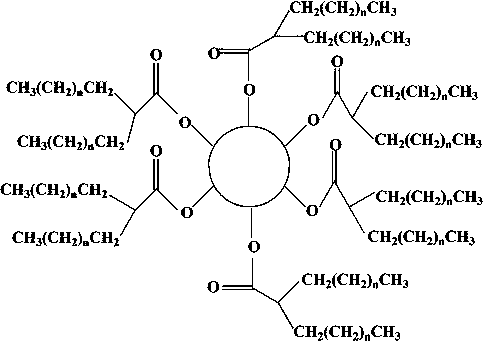

Embodiment approach 1

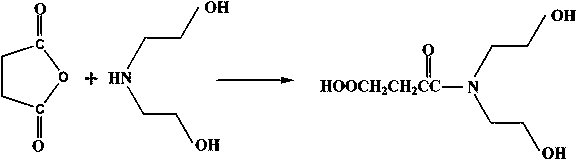

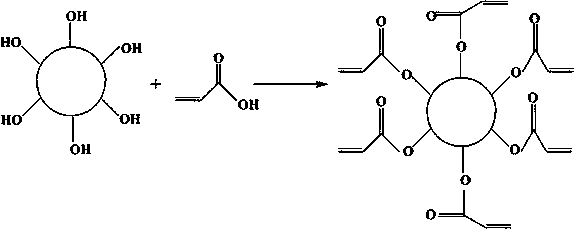

[0029] (1) Weigh 45.032g (0.45mol) of succinic anhydride and 47.313g (0.45mol) of diethanolamine, first add diethanolamine into a three-necked flask with a magnetic stirrer, then dissolve succinic anhydride with an appropriate amount of DMAc; then Put it into the dropping funnel installed on the three-necked bottle of diethanolamine, stir while adding dropwise, after the dropwise addition, raise the temperature to 40°C and react for 12h, and the product of the reaction is AB 2 type monomer. Add 160 mL of toluene (toluene is a water-carrying agent) to the above system first, then add 20.126 g (0.15 mol) of trimethylolpropane as a nuclear molecule, and add 0.500 g of p-toluenesulfonic acid as a catalyst; then start heating until boiling , there is reflux in the spherical condenser tube, and the temperature is raised to 140° C. for 8 hours to obtain a hyperbranched polymer solution with a hydroxyl group at the end. Then weigh 64.854 g (0.90 mol) of acrylic acid and 0.889 g of p-...

Embodiment approach 2

[0033] (1) Weigh 45.032g (0.45mol) of succinic anhydride and 47.313g (0.45mol) of diethanolamine, first add diethanolamine into a three-necked flask with a magnetic stirrer, then dissolve succinic anhydride with an appropriate amount of DMAc; then Put it into the dropping funnel installed on the three-necked bottle of diethanolamine, stir while adding dropwise, after the dropwise addition, raise the temperature to 40°C and react for 12h, and the product of the reaction is AB 2 type monomer. Add 160 mL of toluene (toluene is a water-carrying agent) to the above system first, then add 6.709g (0.05mol) trimethylolpropane as a nuclear molecule, and add 0.500g of p-toluenesulfonic acid as a catalyst; then start heating until boiling , there is reflux in the spherical condenser tube, and the temperature is raised to 140° C. for 8 hours to obtain a hyperbranched polymer solution with a hydroxyl group at the end. Then weigh 43.236 g (0.60 mol) of acrylic acid and 0.778 g of p-toluene...

Embodiment approach 3

[0037] (1) Weigh 45.032g (0.45mol) of succinic anhydride and 47.313g (0.45mol) of diethanolamine, first add diethanolamine into a three-necked flask with a magnetic stirrer, then dissolve succinic anhydride with an appropriate amount of DMAc; then Put it into the dropping funnel installed on the three-necked bottle of diethanolamine, stir while adding dropwise, after the dropwise addition, raise the temperature to 40°C and react for 12h, and the product of the reaction is AB 2 type monomer. Add 160 mL of toluene (toluene is a water-carrying agent) to the above system first, then add 2.952 g (0.022 mol) of trimethylolpropane as a nuclear molecule, and add 0.500 g of p-toluenesulfonic acid as a catalyst; then start heating until boiling , there is reflux in the spherical condenser tube, and the temperature is raised to 140° C. for 8 hours to obtain a hyperbranched polymer solution with a hydroxyl group at the end. Then weigh 36.030 g (0.50 mol) of acrylic acid and 0.742 g of p-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com