Superfine plant powder high-polymer foaming material and preparation method and application thereof

A technology of foaming materials and polymers, which is applied in the field of plant micropowder polymer foaming materials and its preparation, and can solve the problems of unused and poor stability of polymer foaming materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

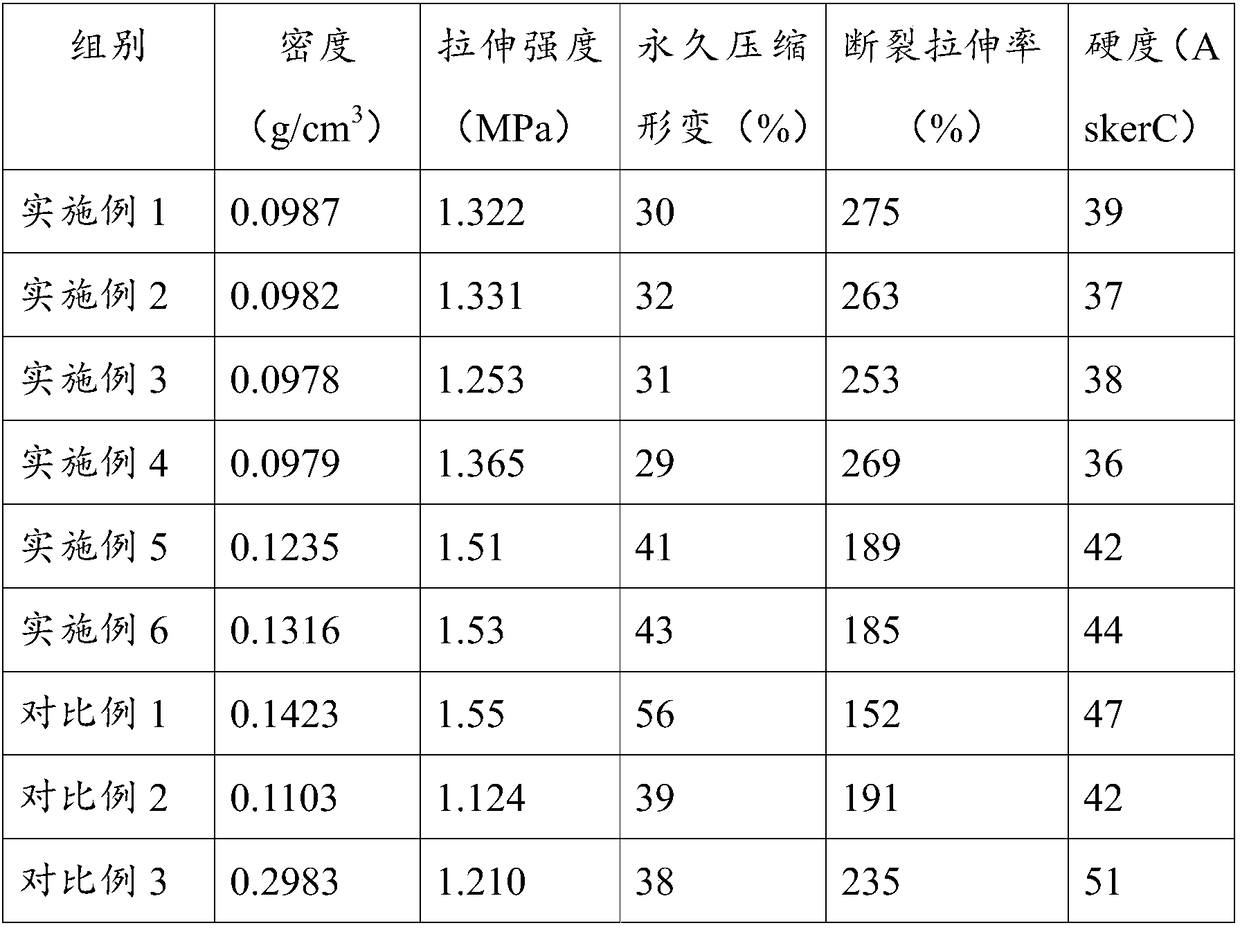

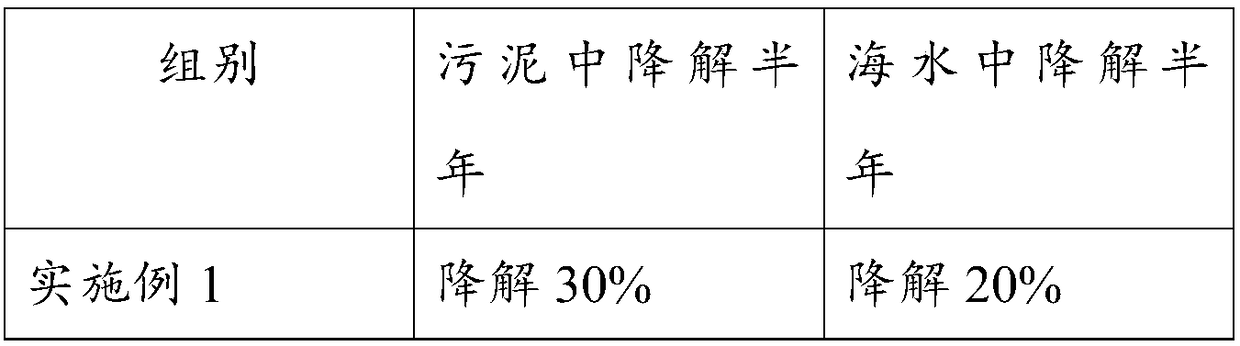

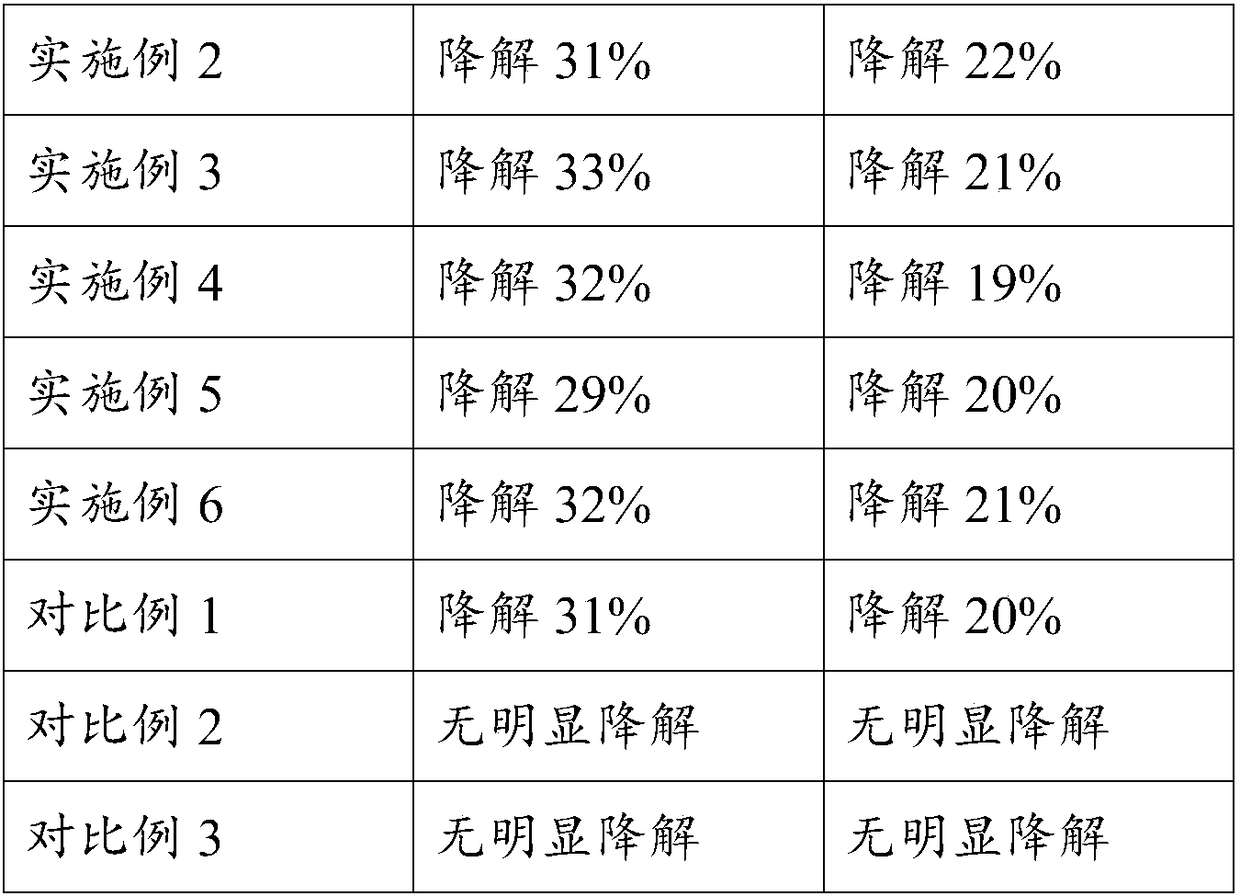

Examples

preparation example Construction

[0024] Some embodiments of the present invention also provide a preparation method of the above-mentioned plant micropowder polymer foaming material, which includes: ethylene-vinyl acetate copolymer, plant micropowder, stearic acid, foaming agent, foaming aid, The kneaded product of the vulcanizing agent and the plant micropowder foaming stabilizer is vulcanized and foamed at a temperature of 160-170°C.

[0025] It should be noted that the vulcanization and foaming process can be carried out better when the raw materials are fully mixed. Therefore, before the vulcanization and foaming process, all raw materials need to be softened and further plasticized to form a gel, so that various raw materials The fluid state can be fully mixed, so that the polymer foam material with better performance can be obtained after vulcanization and foaming. Therefore, various raw materials are kneaded first to obtain a kneaded product, and then vulcanized and foamed.

[0026] Specifically, the ...

Embodiment 1

[0034] The plant micropowder polymer foaming material of the present embodiment is mainly prepared from the following components in parts by weight: 90 parts of ethylene-vinyl acetate copolymer, 20 parts of plant micropowder, 0.5 part of stearic acid, and 2 parts of foaming agent part, 0.5 part of foaming aid, 0.3 part of vulcanizing agent and 10 parts of plant micropowder foaming stabilizer.

[0035] Among them, the plant micropowder is wormwood powder; the plant micropowder foaming stabilizer includes active magnesium oxide and silane coupling agent, the mass ratio of active magnesium oxide and silane coupling agent kh550 is 1:1; the foaming agent is AC foaming agent ; Foaming aid is zinc oxide; vulcanizing agent is vulcanizing agent BIPB.

[0036] The preparation method of this plant micropowder polymer foaming material is:

[0037] First, put ethylene-vinyl acetate copolymer, stearic acid, and plant micropowder in an internal mixer at a temperature of 97°C for the first k...

Embodiment 2

[0043] The plant micropowder polymer foaming material of this embodiment is mainly prepared from the following components in parts by weight: 110 parts of polyethylene, 40 parts of plant micropowder, 2 parts of stearic acid, 8 parts of foaming agent, foaming agent 2 parts of auxiliary agent, 1.5 parts of vulcanizing agent and 20 parts of plant micropowder foaming stabilizer.

[0044] Wherein, the plant fine powder is a mixture of wormwood powder and peppermint powder, and the mass ratio of the wormwood powder and the peppermint powder can be 1:1. The plant micropowder foaming stabilizer includes active magnesium oxide and silane coupling agent kh550, the mass ratio of active magnesium oxide and silane coupling agent is 2:1. Foaming agent is ABS foaming agent. The foaming aid is zinc oxide. The vulcanizing agent is the vulcanizing agent BIPB.

[0045] The preparation method of this plant micropowder polymer foaming material is:

[0046] First, put polyethylene, stearic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com