High-temperature-resistant plastic water bottle and processing method thereof

A processing method and high-temperature-resistant technology, applied in the field of plastic water bottles, can solve the problems of poor aging resistance, short service life, and low use pressure, and achieve the effects of high heat resistance, good aging resistance and increased service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

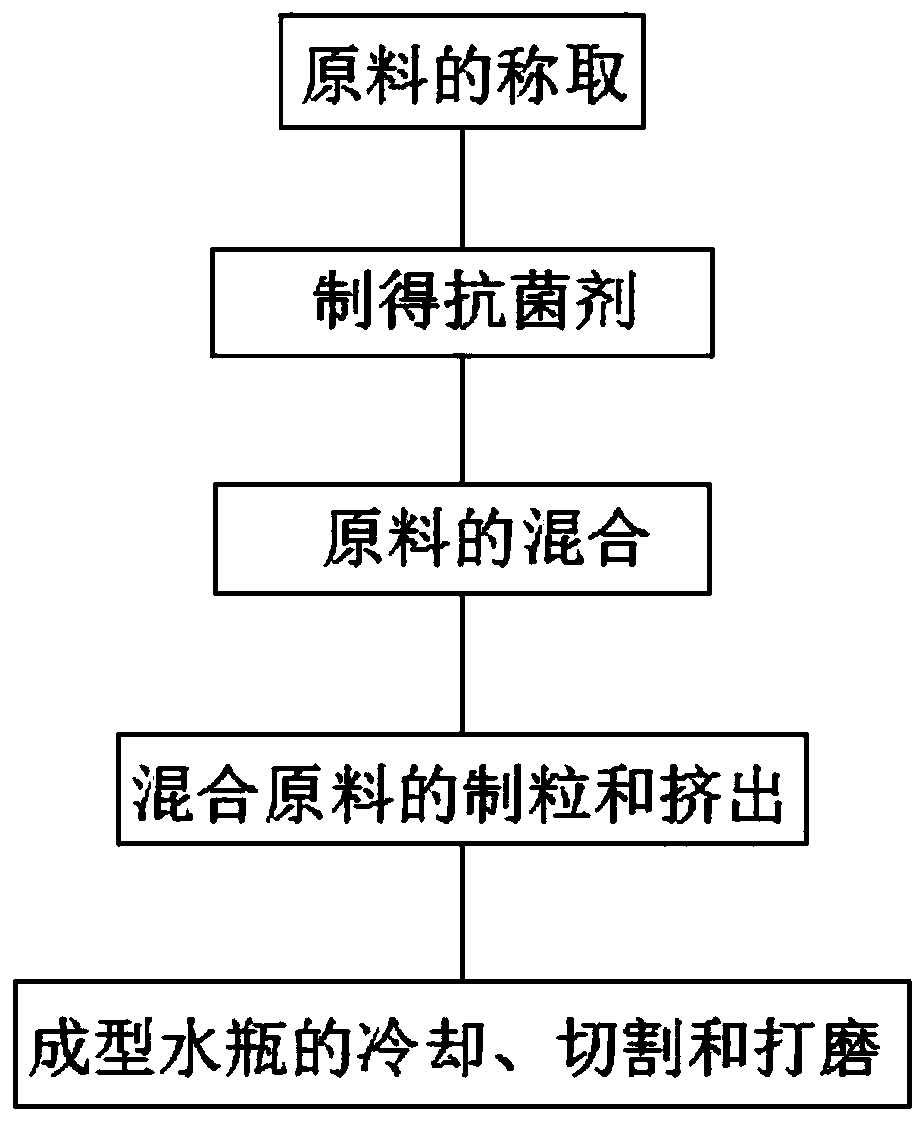

Image

Examples

Embodiment 1

[0034] The high-temperature-resistant plastic water bottle includes the following raw materials and their weight fractions: 55 parts by mass of polyvinyl chloride resin; 18 parts by mass of zinc chloride; 35 parts by mass of zeolite powder; 20 parts by mass of shell powder; 10 parts by mass; 5 parts by mass of coupling agent; 3 parts by mass of dispersant; 10 parts by mass of impact modifier; 0.7 parts by mass of lubricant; 0.5 parts by mass of antioxidant; 2 parts by mass of filler.

[0035] The processing steps are as follows:

[0036] a. taking the above-mentioned raw materials according to parts by weight;

[0037] b. After step a is completed, pour zinc chloride, zeolite powder, shell powder, diluent and coupling agent into the mixer and mix to prepare the antibacterial agent. The mixing temperature is 60-75°C. The time for mixing is 15-20min, and the rotating speed of the mixer is 1250r / min when mixing;

[0038] c. After step b is completed, put the dispersant, impact ...

Embodiment 2

[0042]The high-temperature-resistant plastic water bottle includes the following raw materials and their weight fractions: 55 parts by mass of polyvinyl chloride resin; 45 parts by mass of glass fiber; 18 parts by mass of zinc chloride; 35 parts by mass of zeolite powder; 20 parts by mass; 10 parts by mass of diluent; 5 parts by mass of coupling agent; 3 parts by mass of dispersant; 10 parts by mass of impact modifier; 0.7 parts by mass of lubricant; 0.5 parts by mass of antioxidant; The filler is 2 parts by mass.

[0043] The processing steps are as follows:

[0044] a. taking the above-mentioned raw materials according to parts by weight;

[0045] b. After step a is completed, pour zinc chloride, zeolite powder, shell powder, diluent and coupling agent into the mixer and mix to prepare the antibacterial agent. The mixing temperature is 60-75°C. The time for mixing is 15-20min, and the rotating speed of the mixer is 1250r / min when mixing;

[0046] c. After step b is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com