Non-cured rubber asphalt waterproof coating and preparation process thereof

A technology of asphalt waterproof coating and non-curing rubber, applied in asphalt coatings, fireproof coatings, coatings, etc., can solve the problems of uneven performance, affecting the waterproof performance requirements of buildings, tearing of waterproof coatings, etc., and prolong the service life. , Improve the high and low temperature stability and adhesion, the effect of not easy to tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

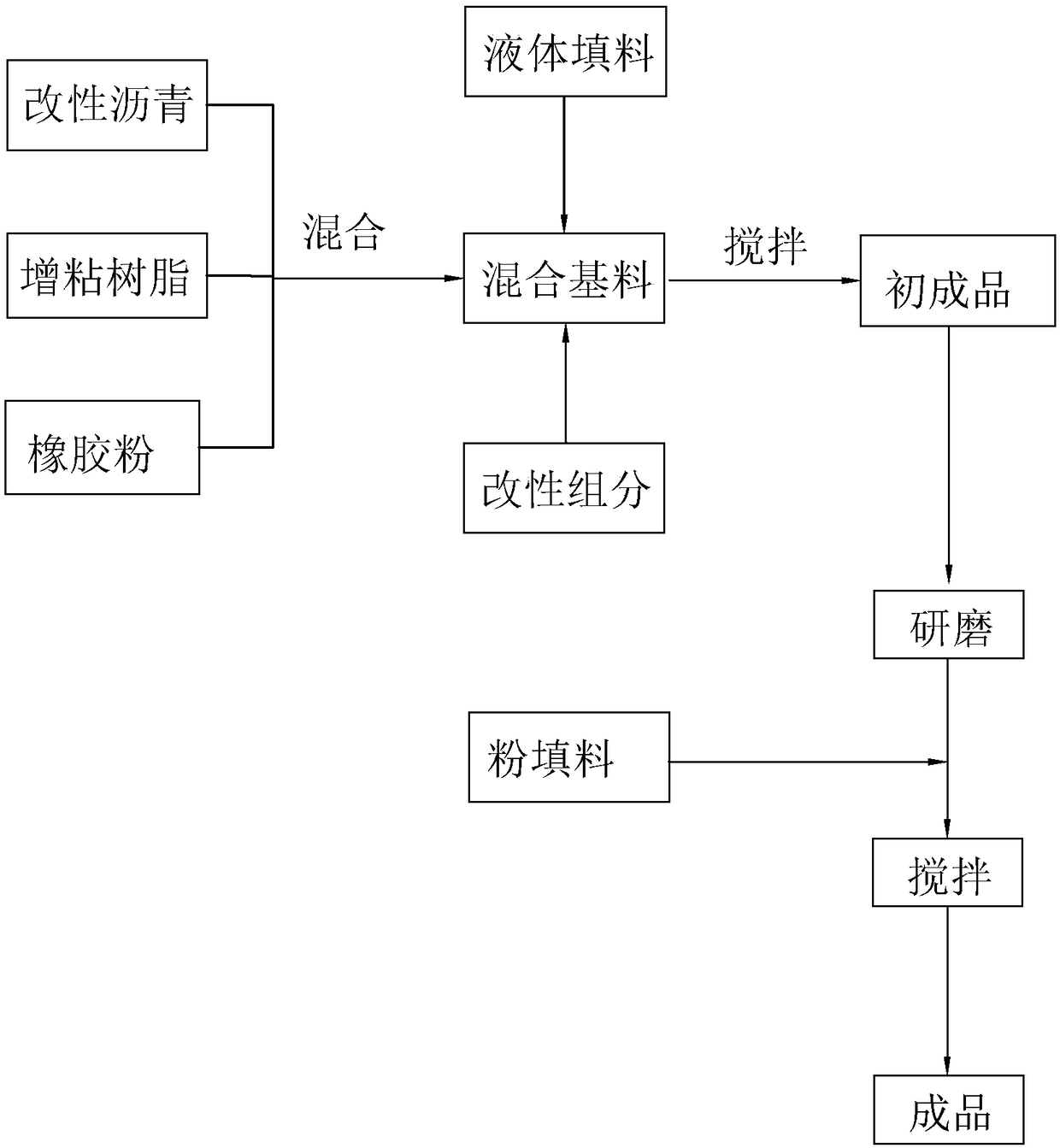

Method used

Image

Examples

Embodiment 1

[0032] Example 1: A modified asphalt, including base asphalt, PE and SBS, and the weight ratio of the three is 96:3:1.

Embodiment 2

[0033] Embodiment 2: A modified asphalt, including base asphalt, PE and SBS, and the weight ratio of the three is 92:5:3.

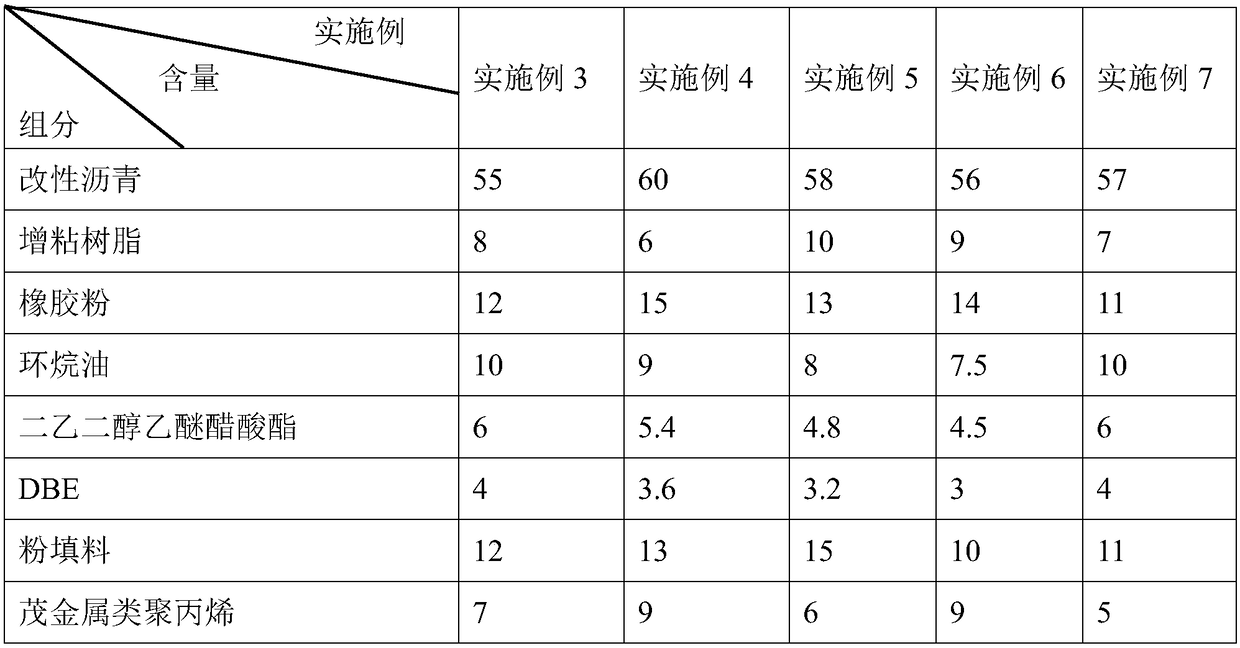

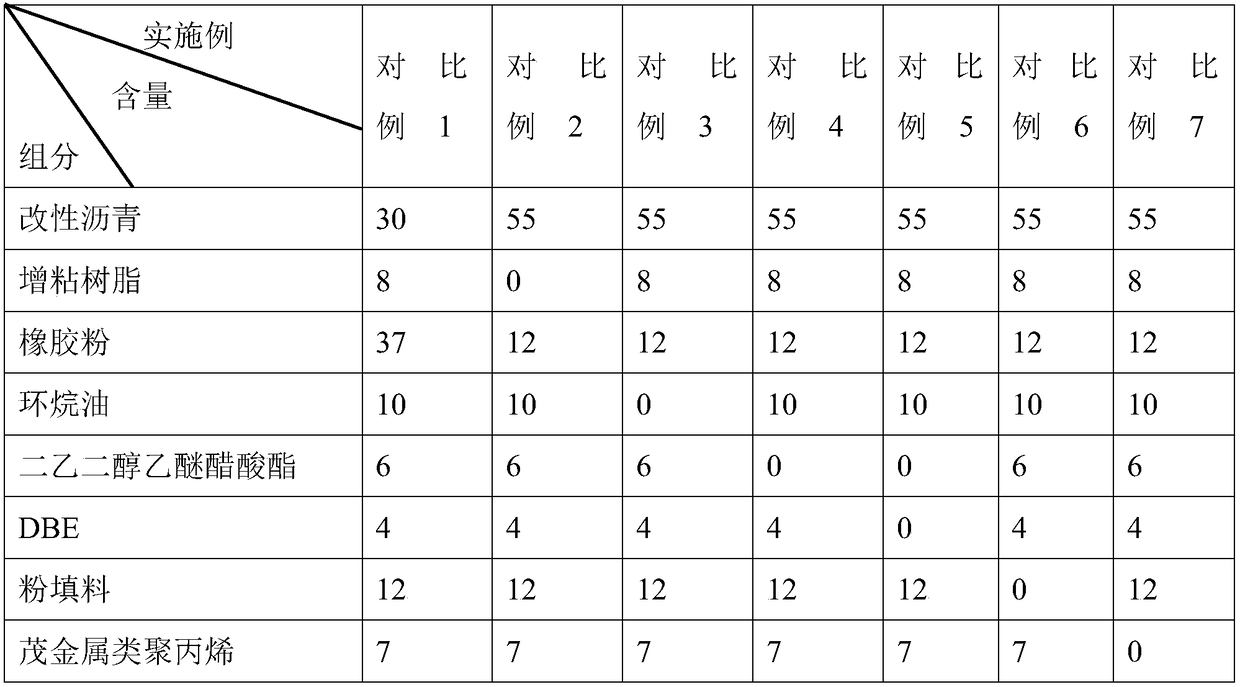

Embodiment 3-7

[0034] Embodiment 3-7: a kind of non-cured rubber asphalt waterproof coating, the component that comprises and corresponding weight are as shown in table 1, wherein modified asphalt adopts the product obtained in embodiment 1, and tackifying resin comprises petroleum hydrogenated resin, Styrene-butadiene rubber and chloroprene rubber, and petroleum hydrogenated resin accounts for 25% by weight of the tackifying resin; the rubber powder needs to be filtered and screened, and the particle diameter of the rubber powder is controlled to be less than 40 mesh during screening; naphthenic oil in the liquid filler, The mass ratio of diethylene glycol ethyl ether acetate to DBE is 5:3:2; the weight ratio of fly ash and silicon dioxide powder in the powder filler is 3:2.

[0035] Each component and its corresponding weight table (kg) in the embodiment 3-7 of table 1

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com