Low-modulus elastic sealant and preparation method thereof

An elastic sealing, low modulus technology, used in adhesives, adhesive types, polyether adhesives, etc., to solve problems such as poor overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

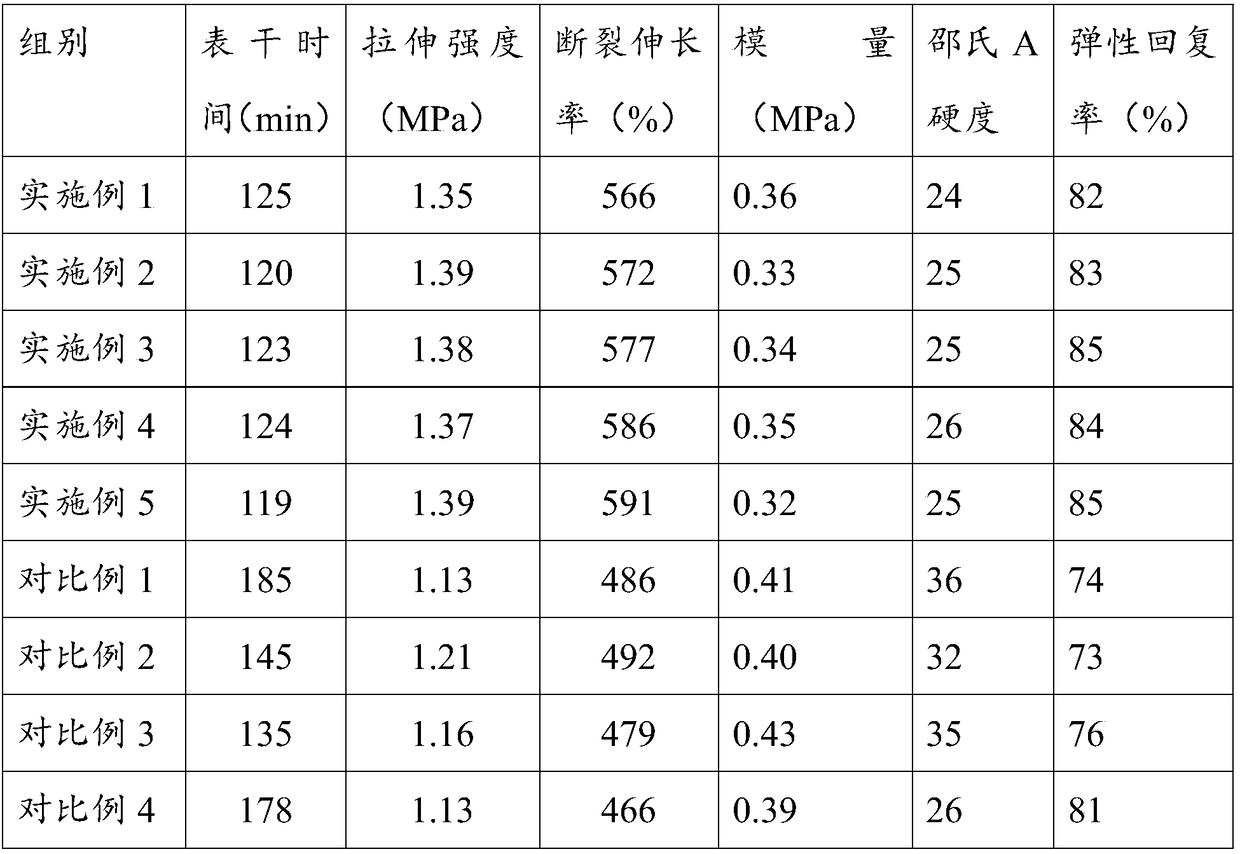

Examples

preparation example Construction

[0023] Some embodiments of the present invention also provide a preparation method of the above-mentioned low modulus elastic sealant, which includes:

[0024] S1. Stir the plasticizer, calcium carbonate and activated calcium carbonate and remove moisture and air bubbles in a vacuum to obtain the first product.

[0025] Specifically, the plasticizer, calcium carbonate and activated calcium carbonate are stirred at a rotating speed of 950 to 1150rpm, and the above-mentioned raw materials can be fully mixed evenly through high-speed stirring, and the air bubbles between the raw materials are also easily removed. The process of stirring and vacuum removing moisture and air bubbles is carried out at a temperature of 85-95°C. At this temperature, moisture and air bubbles can easily escape from the raw materials and be effectively removed, which is beneficial to the subsequent reaction. Reaction effect. Wherein, the degree of vacuum for vacuum removal is 0.05-0.08Mpa.

[0026] S2....

Embodiment 1

[0032] The low modulus elastic sealant of the present embodiment, in parts by weight, its raw materials include: 20 parts of German Wacker E35.xm25, 10 parts of butyl benzyl phthalate, 20 parts of calcium carbonate, 20 parts of activated calcium carbonate , 1 part of fumed silica, 1 part of silane coupling agent a171, 0.5 part of silane coupling agent kh550, 0.5 part of light stabilizer Tinuvin 765, 0.5 part of antioxidant and 0.2 part of catalyst TBTDL.

[0033] The preparation method of this low modulus elastic sealant is:

[0034] First, the plasticizer, calcium carbonate and activated calcium carbonate were stirred and mixed at a rotational speed of 950 rpm, and moisture and air bubbles were removed in a vacuum at a temperature of 85° C. at a vacuum degree of 0.05 MPa.

[0035] Next, at a temperature of 60° C., continue to maintain the rotation speed, add fumed silica, silane-modified polyether, and a water-removing agent for mixing, and react for 25 minutes.

[0036] The...

Embodiment 2

[0038] The low-modulus elastic sealant of the present embodiment, in parts by weight, its raw materials include: 25 parts of German Wacker E35.xm25, 20 parts of butyl benzyl phthalate, 30 parts of calcium carbonate, 40 parts of activated calcium carbonate , 5 parts of fumed silica, 2 parts of silane coupling agent a171, 1 part of silane coupling agent kh550, 1.5 parts of light stabilizer Tinuvin 765, 1.5 parts of antioxidant and 0.3 parts of catalyst TBTDL.

[0039] The preparation method of this low modulus elastic sealant is:

[0040] First, the plasticizer, calcium carbonate and activated calcium carbonate were stirred and mixed at a rotation speed of 1150 rpm, and moisture and air bubbles were removed in a vacuum at a temperature of 95° C. at a vacuum degree of 0.08 MPa.

[0041] Secondly, at a temperature of 90° C., while continuing to maintain the rotational speed, add fumed silica, silane-modified polyether, and a water-removing agent for mixing, and react for 35 minutes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com