Composite phase change material for thermal batteries and method for preparing composite phase change material

A technology of composite phase change materials and thermal batteries, which is applied in the field of composite phase change materials for thermal batteries and its preparation, can solve problems such as difficulty in ensuring safety during working hours, and achieve rapid response to heat changes, improve capillary adsorption effects, The effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: a kind of preparation method of thermal battery composite phase change material, comprises the following steps:

[0017] Step 1. Mixing: Melt 159.6 parts of LiF, 332.5 parts of Li2SO4, and 172.9 parts of LiCl into a liquid state at 600 ° C. After cooling and solidifying, pulverize to obtain a pulverized product, and then add 35 parts of foamed graphite to the pulverized product. 400r / min~1200r / min high-energy ball mill to get the mixture after mixing evenly;

[0018] Step 2, immersion: the mixture is evenly distributed on 300 parts of porous MgO, and then placed in a high temperature environment of 600° C. for 2 to 4 hours, and the composite phase change material can be obtained after cooling.

[0019] The specific heat capacity before melting of the composite phase change material is 0.63J / g, the phase change temperature range is 470.3°C-493.2°C, and the latent heat of phase change is 277.4J / g. One of them is 1g. Take 14g of composite phase change materi...

Embodiment 2

[0020] Embodiment 2: a kind of preparation method of thermal battery composite phase change material, comprises the following steps:

[0021] Step 1. Mixing: Melt 159.6 parts of LiF and 505.4 parts of LiCl into a liquid state at 650°C, cool and solidify, and then pulverize to obtain a pulverized product, then add 35 parts of foamed graphite to the pulverized product at a speed of 400r / min~1200r / min of the high-energy ball mill to obtain the mixture;

[0022] Step 2, immersion: the mixture is evenly distributed on 300 parts of porous MgO, and then placed in a high temperature environment of 650° C. for 2 to 4 hours, and the composite phase change material can be obtained after cooling.

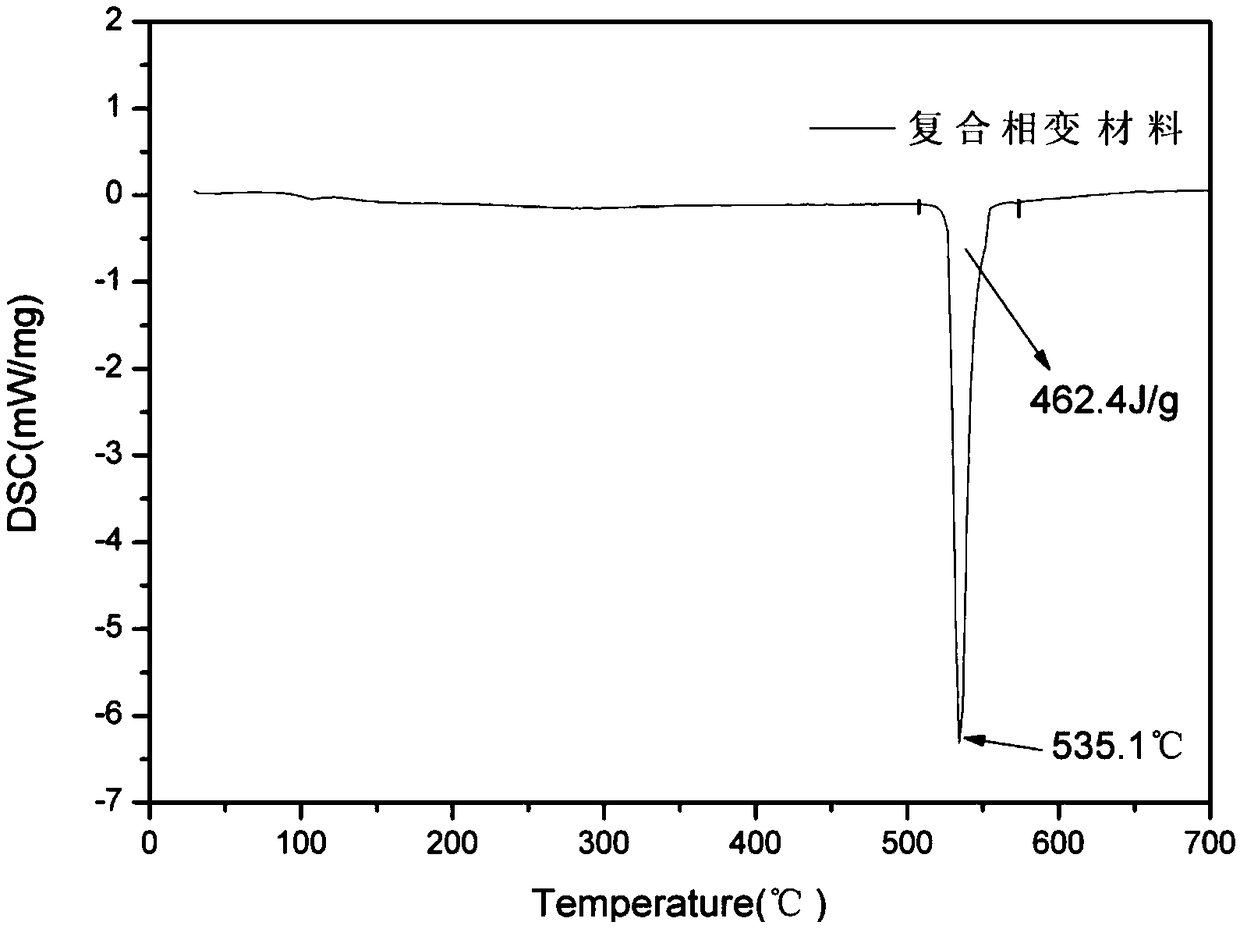

[0023] The specific heat capacity before melting of the composite phase change material is 0.72J / g, the phase change temperature range is 527.3°C-543.2°C, and the latent heat of phase change is 462.4J / g. One of them is 10g, such as figure 1 As shown, take 14g of composite phase-change materi...

Embodiment 3

[0024] Embodiment 3: a kind of preparation method of thermal battery composite phase-change material, comprises the following steps:

[0025] Step 1. Mixing: Melt 151.2 parts of LiF and 478.8 parts of LiCl into a liquid state at 650°C, cool and solidify, and then pulverize to obtain a pulverized product, then add 70 parts of foamed graphite to the pulverized product, at a speed of 400r / min~1200r / min of the high-energy ball mill to obtain the mixture;

[0026] Step 2, immersion: the mixture is evenly distributed on 300 parts of porous MgO, and then placed in a high temperature environment of 650° C. for 2 to 4 hours, and the composite phase change material can be obtained after cooling.

[0027] The specific heat capacity before melting of the composite phase change material is 0.72J / g, the phase change temperature range is 527.3°C-543.2°C, and the latent heat of phase change is 389.1J / g. One of them is 1g. Take 14g of composite phase change material and press it into a sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com