A blade printing electrospinning device and its use method

An electrospinning and printing technology, which is applied in the field of blade printing electrospinning devices, achieves the effects of good solution concentration control, improved efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

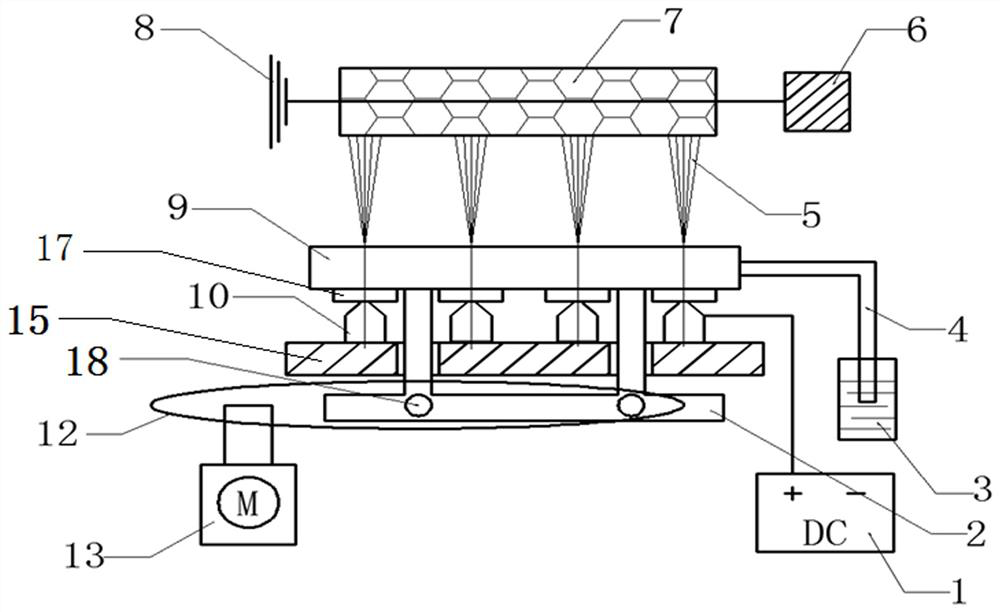

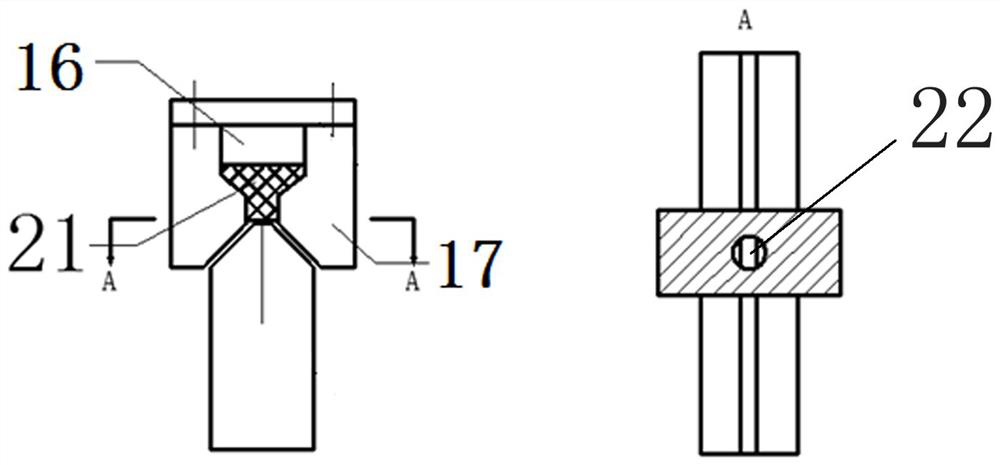

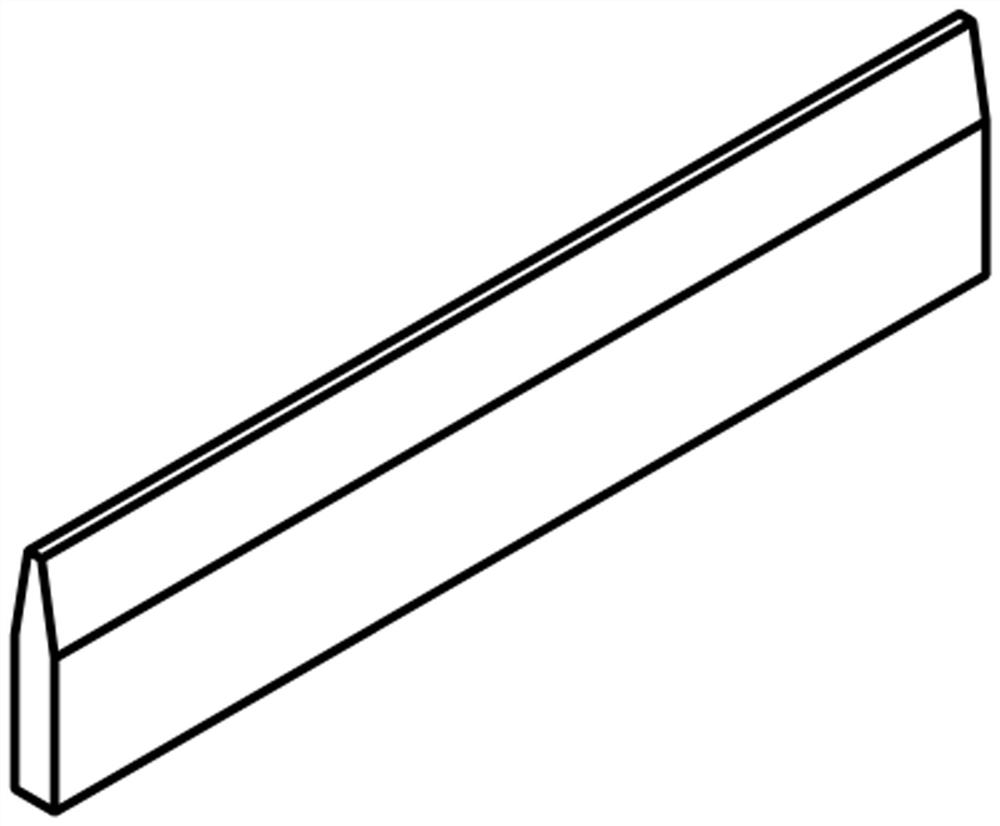

[0031] Such as Figure 1-3 A blade printing electrospinning device shown includes a liquid storage bottle 3 and a liquid guide pipe 4, the liquid guide pipe 4 is connected to the brush shaft 16 arranged on the support frame 9, and the brush shaft 16 is connected to the printing nozzle 17 is connected through a round hole 22, a blade 10 is provided under the printing nozzle 17, and the blade 10 is arranged on the base 15, and the base 15 is provided with a track for moving the mobile frame 2, and the top of the mobile frame 2 is fixed on the supporting frame 9, The bottom cross bar is connected to the output end of the motor II 13 through the transmission mechanism, the positive pole of the high voltage generator 1 is connected to the blade 10 through the bearing; the lower part of the liquid guide pipe 4 is connected to the peristaltic pump 5; the upper part of the support frame 9 is provided with a metal roller 7 , the rotating shaft in the metal drum 7 is connected to the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com