Preparation method of novel polyacrylonitrile fiber material

A polyacrylonitrile fiber, a new type of technology, applied in the direction of fiber type, fiber processing, textile and paper making, etc., to avoid solvent waste, save reaction raw materials, and reduce raw material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

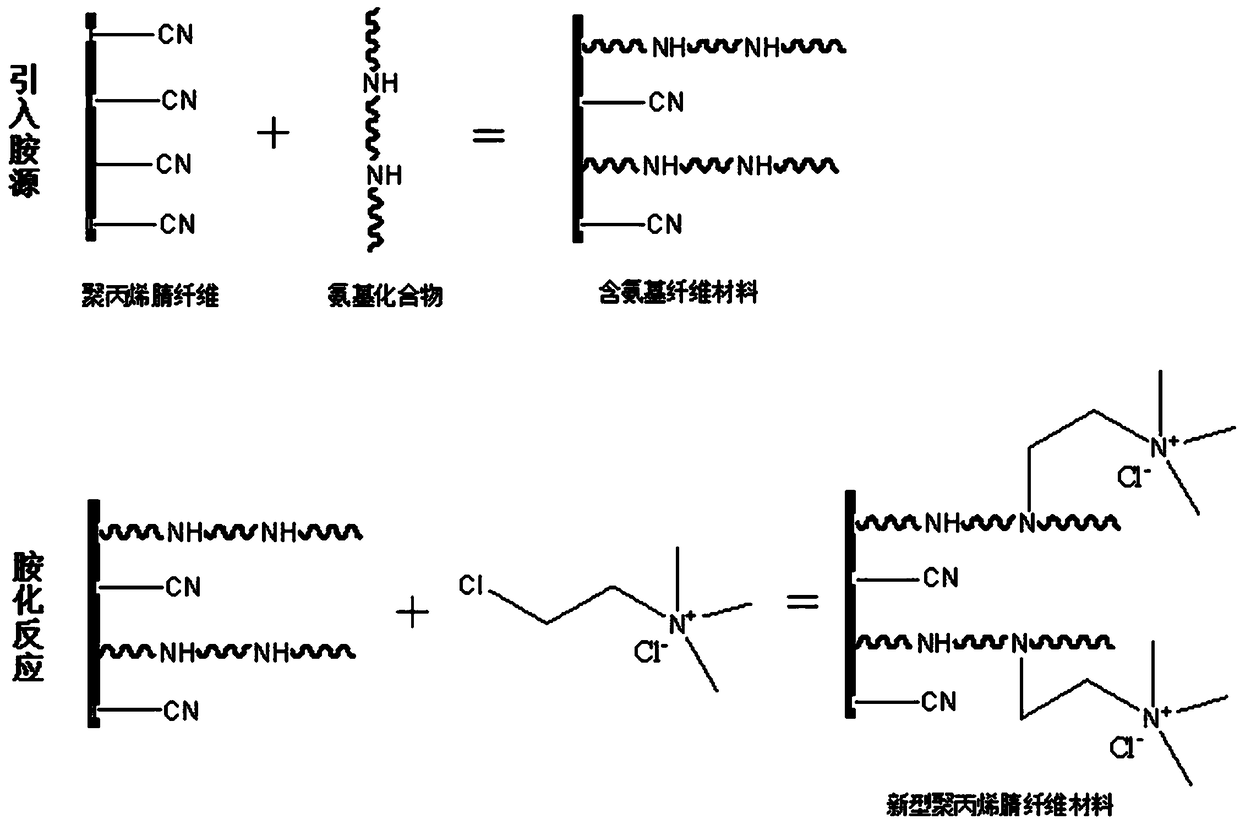

Method used

Image

Examples

Embodiment 1

[0016] Put 600 mL of diethylenetriamine solvent directly into the reaction flask, and after stirring evenly, add 15 g of polyacrylonitrile fiber, and stir evenly at 115°C for 4 h. After the reaction, the fibers were cooled and taken out, and washed with deionized water at 70°C until neutral to obtain a light yellow amino-containing fiber material. Put 10 g of amino-containing fiber material into 300 mL of 10% chlormequat (2-chloroethyltrimethylammonium chloride) solution, then react at 90 °C for 4 h, and the obtained product was washed with deionized water. Dry to constant weight at 50-80°C to obtain off-white fiber material.

Embodiment 2

[0018] Put 750 mL of diethylene solvent directly into the reaction flask, stir evenly, add 15 g of polyacrylonitrile fibers, and stir evenly at 105°C for 4 h. After the reaction, the fibers were cooled and taken out, and washed with deionized water at 70°C until neutral to obtain a light yellow amino-containing fiber material. Put 15 g of amino-containing fiber materials into 600 mL of 10% chlormequat (2-chloroethyltrimethylammonium chloride) solution, then react at 85 °C for 3.5 h, and the obtained product was washed with deionized water, Dry to constant weight at 50-80°C to obtain off-white fiber material.

Embodiment 3

[0020] Put 600 mL of polyethylene polyamine solvent directly into the reaction flask, stir evenly, add 15 g of polyacrylonitrile fibers, and stir evenly at 110°C for 3 h. After the reaction, the fibers were cooled and taken out, and washed with deionized water at 70°C until neutral to obtain a light yellow amino-containing fiber material. Put 15 g of amino-containing fiber materials into 750 mL of 10% chlormequat (2-chloroethyltrimethylammonium chloride) solution, and then react at 85 °C for 3.5 h, and the obtained product was washed with deionized water. Dry to constant weight at 50-80°C to obtain off-white fiber material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap