Dam-free water flow turbine power generation system

A power generation system and water flow technology, applied in hydroelectric power generation, ocean energy power generation, engine components, etc., can solve problems affecting surrounding residents and power station staff, lack of flexibility, and inability to move at will.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

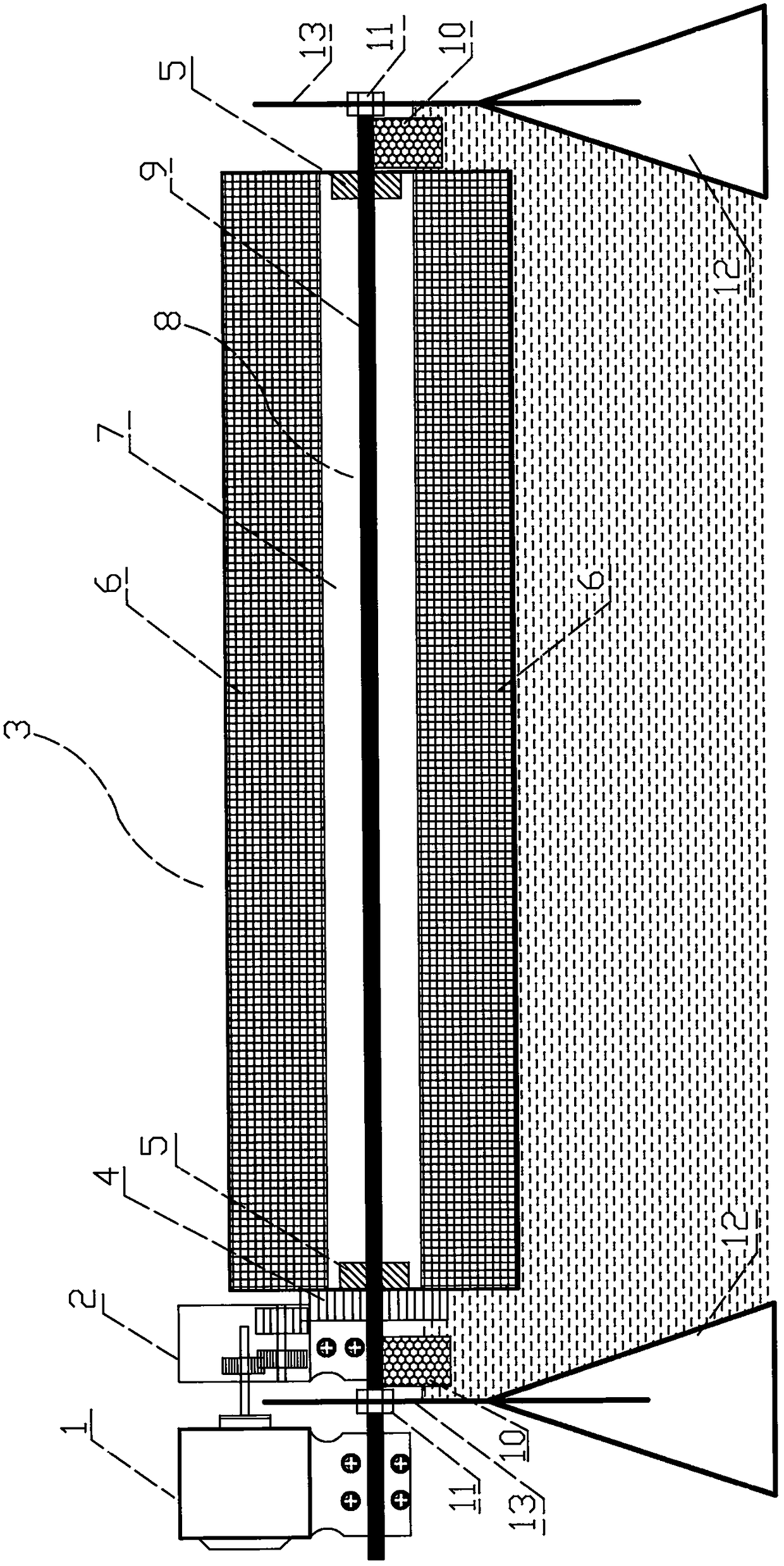

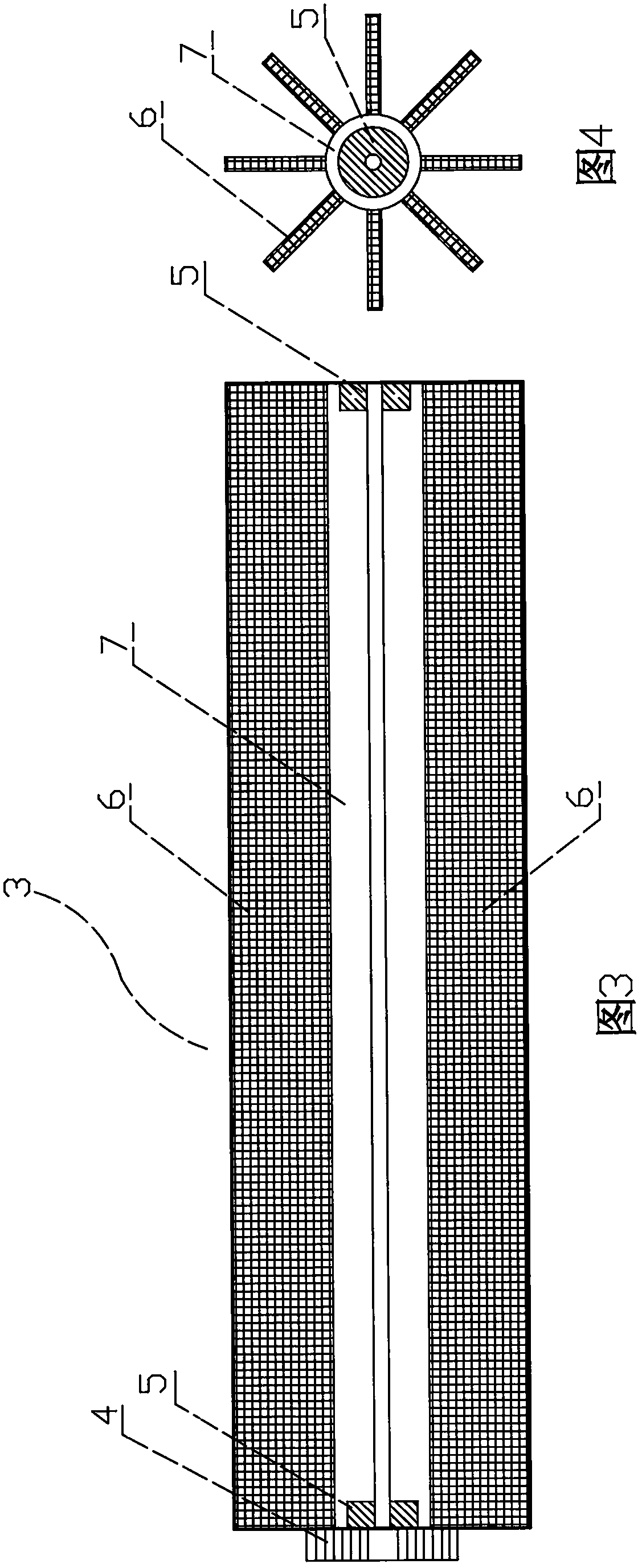

[0022] Such as figure 1 , figure 2 As shown, the power generation system mainly includes a generator 1, a speed change gear set 2, a barrage central shaft part 8, a turbine blade 3 and a stable support 12, wherein the barrage central shaft part 8 is perpendicular to the direction of water flow and half floats on the water surface. The middle axis part 8 of the barrage is kept supported under the action of the stable brackets 12 located at both ends of the river bank, and the turbine blade 3 placed on the middle axis part 8 of the river barrage rotates under the action of the impact of the water flow, thereby driving the speed change gear set 2 to run and finally generating electricity Machine 1 works to generate electricity.

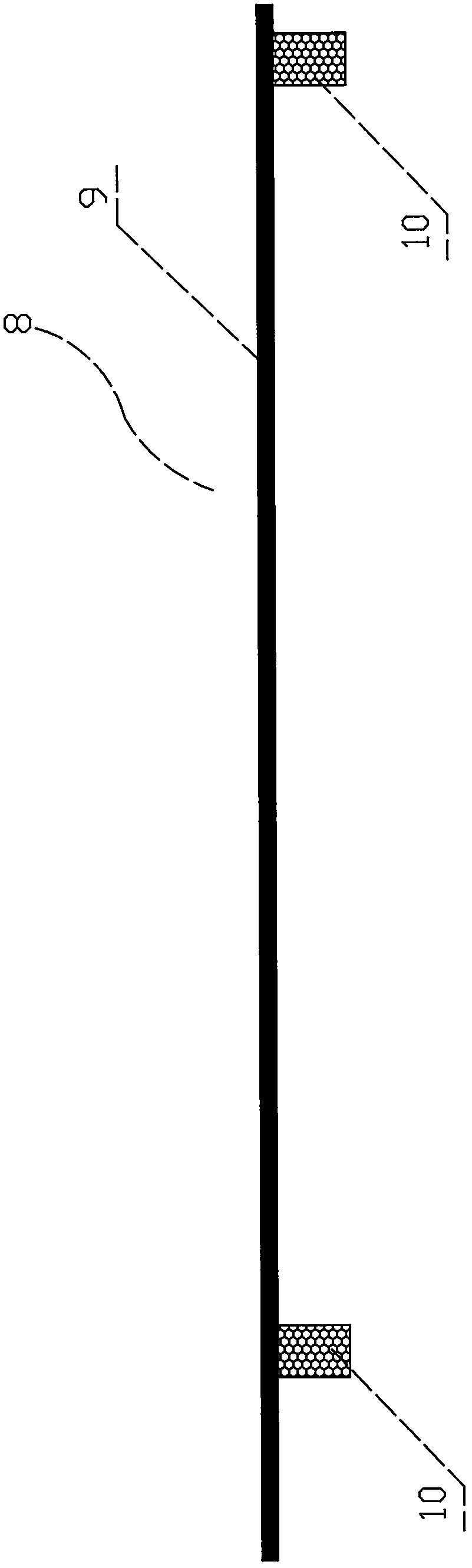

[0023] Such as figure 2 , image 3 with Figure 4 As shown, the barrage central axis part 8 is composed of the barrage central axis 9 and the floating depth control device 10. The central axis of the turbine blade 3 is hollow, that is, the hollow s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com