A method for measuring blade tip clearance based on microwave frequency sweep

A technology of blade tip clearance and measurement method, which is applied in the direction of measuring devices, instruments, and electric devices, etc., can solve the problems of resonance frequency point drift, measurement accuracy affected by temperature, etc., and achieve the effect of wide dynamic range and elimination of common mode error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

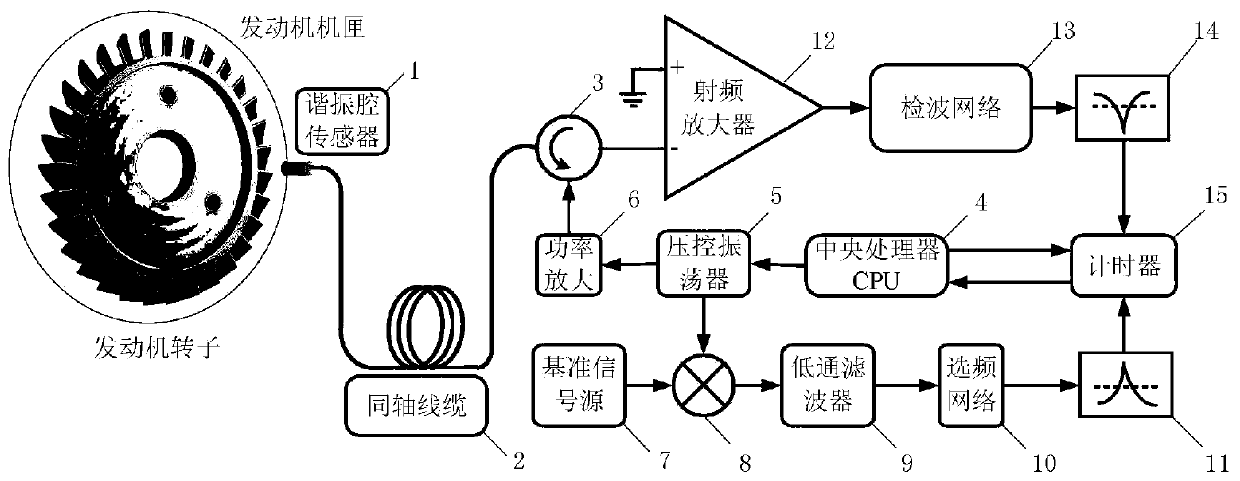

[0021] The present invention proposes a moving blade tip clearance measurement system based on the microwave frequency sweeping working mode, such as figure 1 As shown, it includes: resonant cavity sensor 1, coaxial cable 2, circulator 3, central processing unit (CPU) 4, voltage controlled oscillator (VCO) 5, radio frequency power amplifier 6, reference signal source 7, mixer 8. Low pass filter 9, frequency selection network 10, reference time discriminator 11, radio frequency low noise amplifier 12, detection network 13, resonance time discriminator 14, timer 15.

[0022] The central processing unit (CPU) 4 generates a voltage signal modulated by a sawtooth wave or a triangular wave to control a voltage-controlled oscillator (VCO) 5 to realize linear and fast frequency sweep. At the second level, output two channels of reference signals of the same frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com