Laser ranging module and ranging method

A laser ranging and laser technology, which is used in measurement devices, radio wave measurement systems, instruments, etc., can solve the problem that the ranging device cannot meet the accuracy requirements of the print head, the measurement accuracy and cost are high, and the equipment is not easy to install and print. First-class problem, to achieve the effect of increasing application scalability, realizing automatic zero adjustment function, and low-cost installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] Specific embodiments one, the following will be combined with the attached Figure 1-5 , the present invention is described in detail:

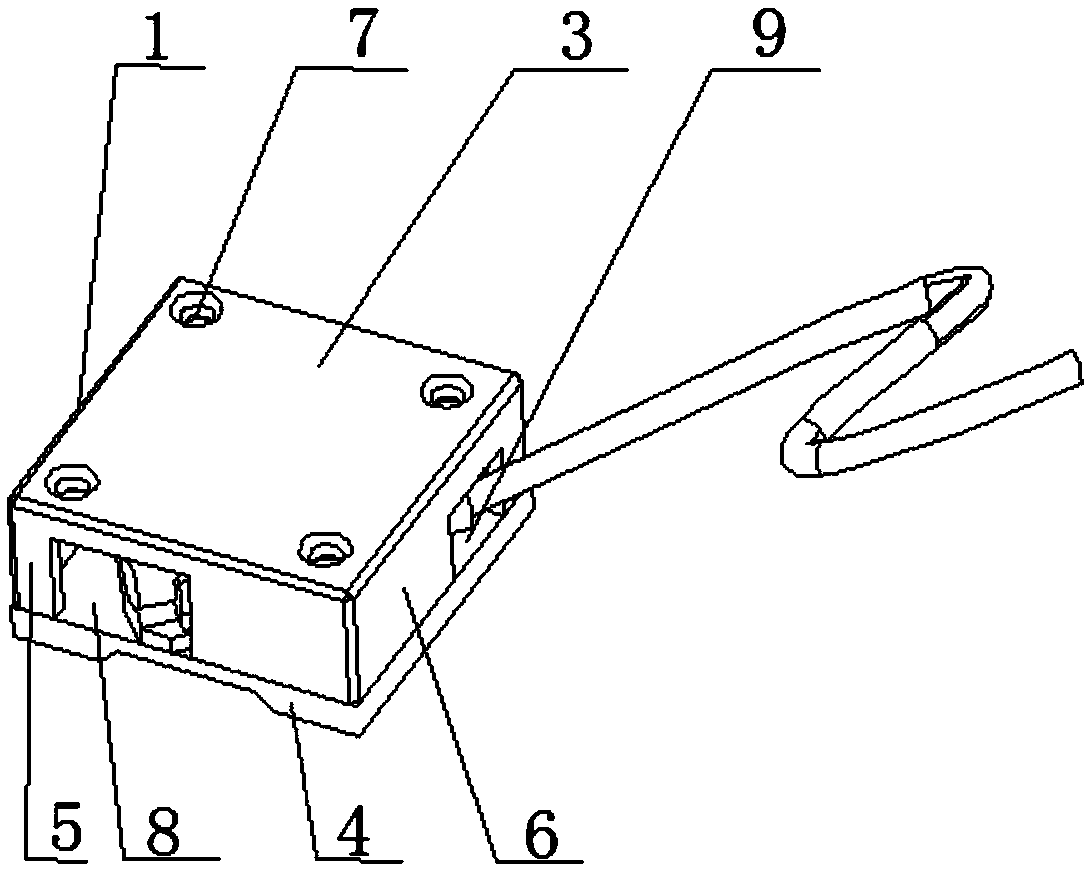

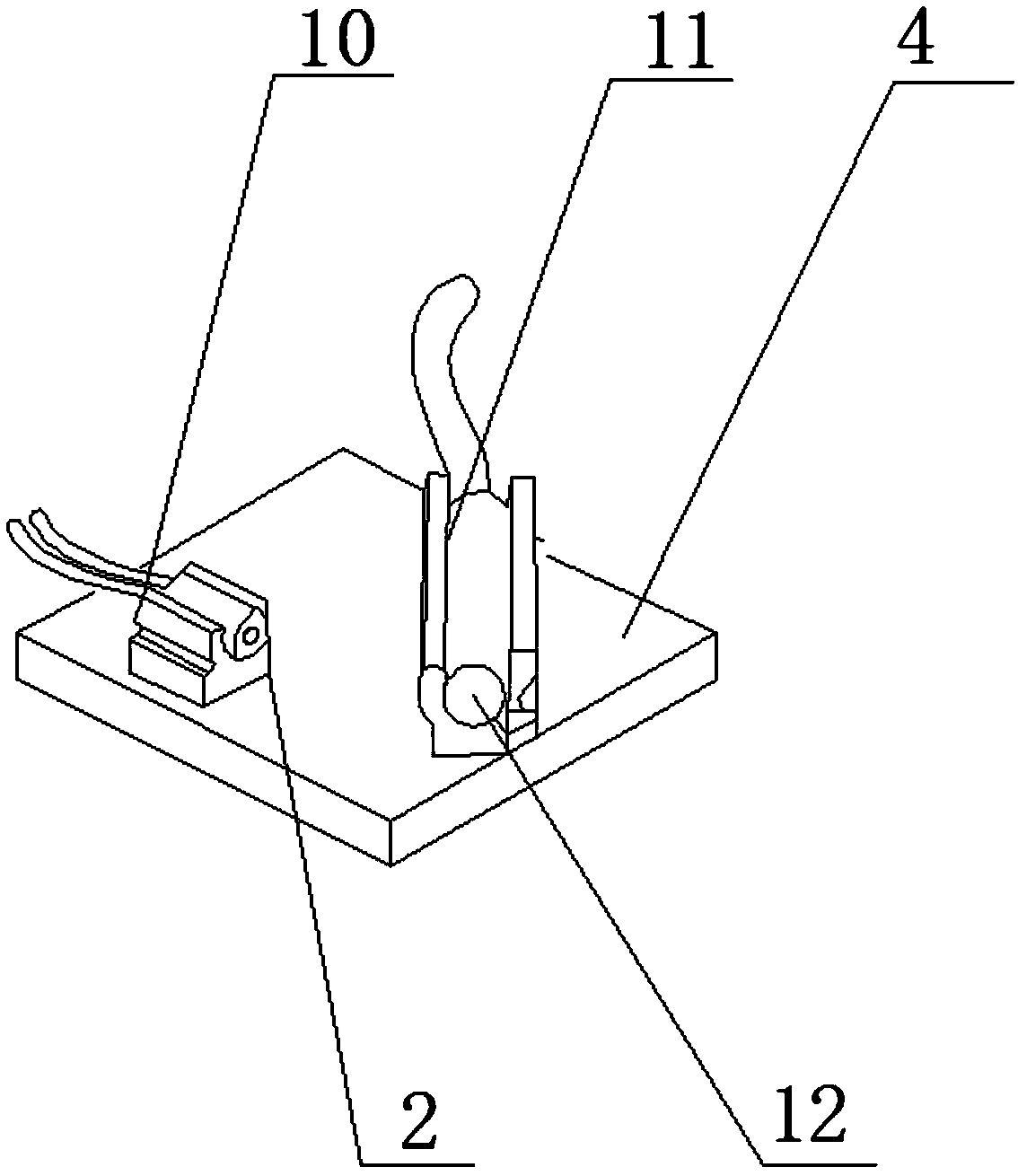

[0029] A kind of laser ranging module of the present invention is to solve the above-mentioned problem and adopts the technical scheme that comprises laser ranging box 1 and laser ranging device 2, and laser ranging box 1 is a square box structure, and laser ranging device 2 Installed inside the laser ranging box 1, the laser ranging box 1 includes an upper shell 3, a lower shell 4, a first support plate 5 and a second support plate 6, the upper shell 3 is arranged on the lower shell 4 Above, the surrounding area between the upper shell plate 3 and the lower shell plate 4 is supported by the first support plate 5 and the second support plate 6, four screw holes 7 are processed at the four corners of the upper shell plate 3, the first The left side of the support plate 5 is provided with a distance measuring hole 8, and the right side ...

specific Embodiment approach 2

[0030] Specific implementation mode two, the following will be combined with the attached Figure 1-5 , the present invention is described in detail:

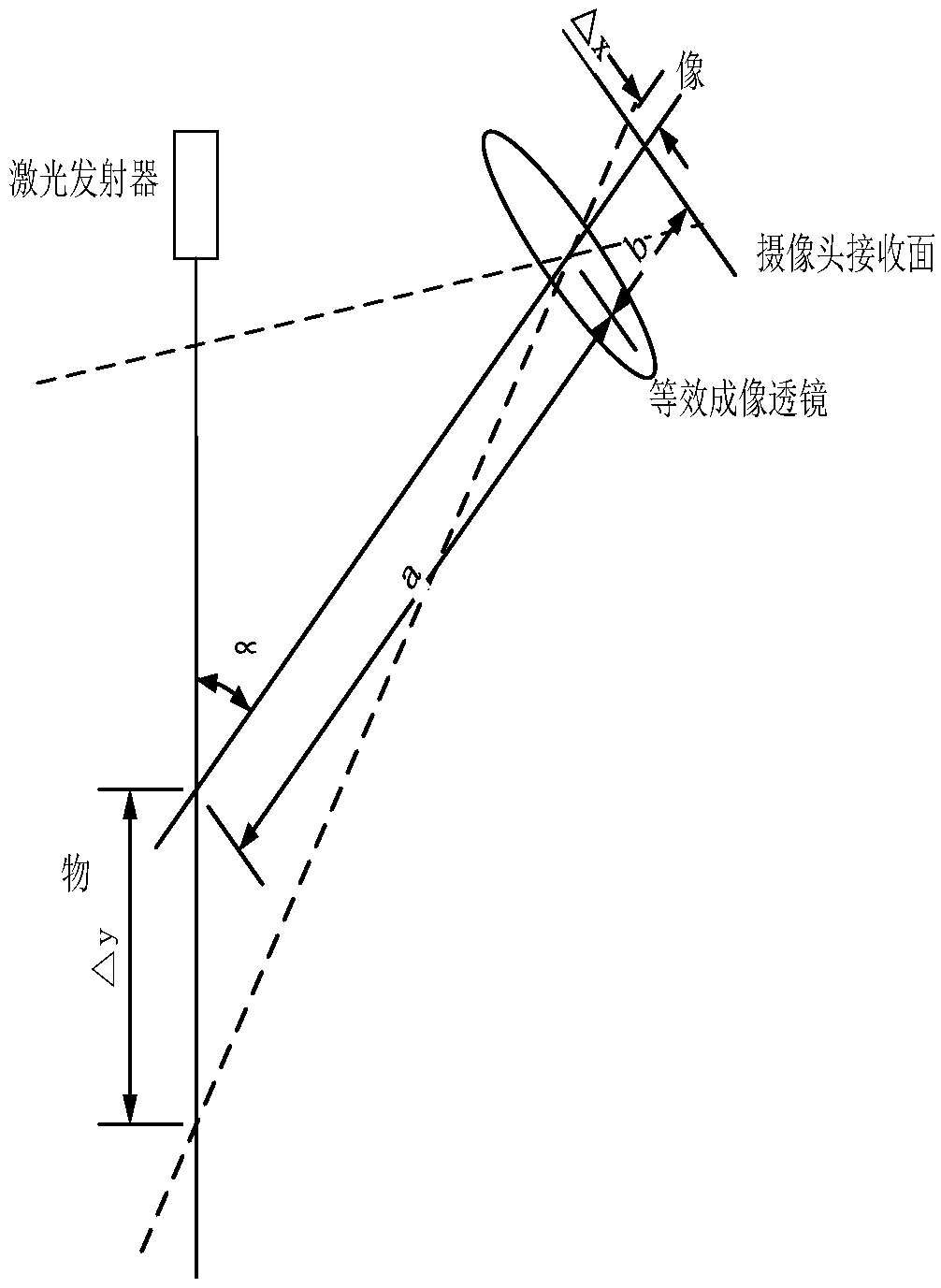

[0031] The laser 10 is perpendicular to the platform, that is, the angle between the emitted laser ray axis and the imaging axis of the camera 11 is α,

[0032] Step a, record the movement of the object along the direction of the laser ray as shown in Δy;

[0033] Step b, record that the image of the object in the receiving surface of the camera 11 moves Δx accordingly;

[0034] Step c, if the object moves along the direction of the laser ray as shown in the figure Δy, the image of the object in the receiving surface of the camera 11 will move Δx accordingly. Generally, the measurement range of the laser ranging is much larger than the effective length of the receiving surface of the camera 11, so the lens system The resulting image is a reduced image, and the relationship between the displacement of the object and the displa...

specific Embodiment approach 3

[0037] Specific implementation mode three, the following will be combined with the attached Figure 1-5 , the present invention is described in detail:

[0038] A laser ranging method,

[0039] Step 1. Obtain the displacement relationship between the displacement of the printer object and the image;

[0040] Step 2. Obtain the Z-axis coordinate position of the printing platform in the current coordinate system;

[0041] Step 3. When the upper computer control program wants to print and transmit the print file, it performs Z-axis coordinate processing, and the upper computer control program processes the print file according to the height of the platform and then transmits it to the printer;

[0042] Step 4, the printer prints the received file to realize printing on the printing platform;

[0043]The host computer control program will realize the semi-automatic calibration of the laser module. First, let the extrusion head and the laser module installed on the extrusion hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com