A method for implementing intelligent warehouse integration

An implementation method and intelligent technology, applied in the field of warehousing and logistics, can solve problems such as hidden dangers of warehouse safety, increase of uncontrollable factors, unfavorable warehouse management and use, etc., to reduce personnel labor intensity and warehouse management costs, improve efficiency and lean level. , the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

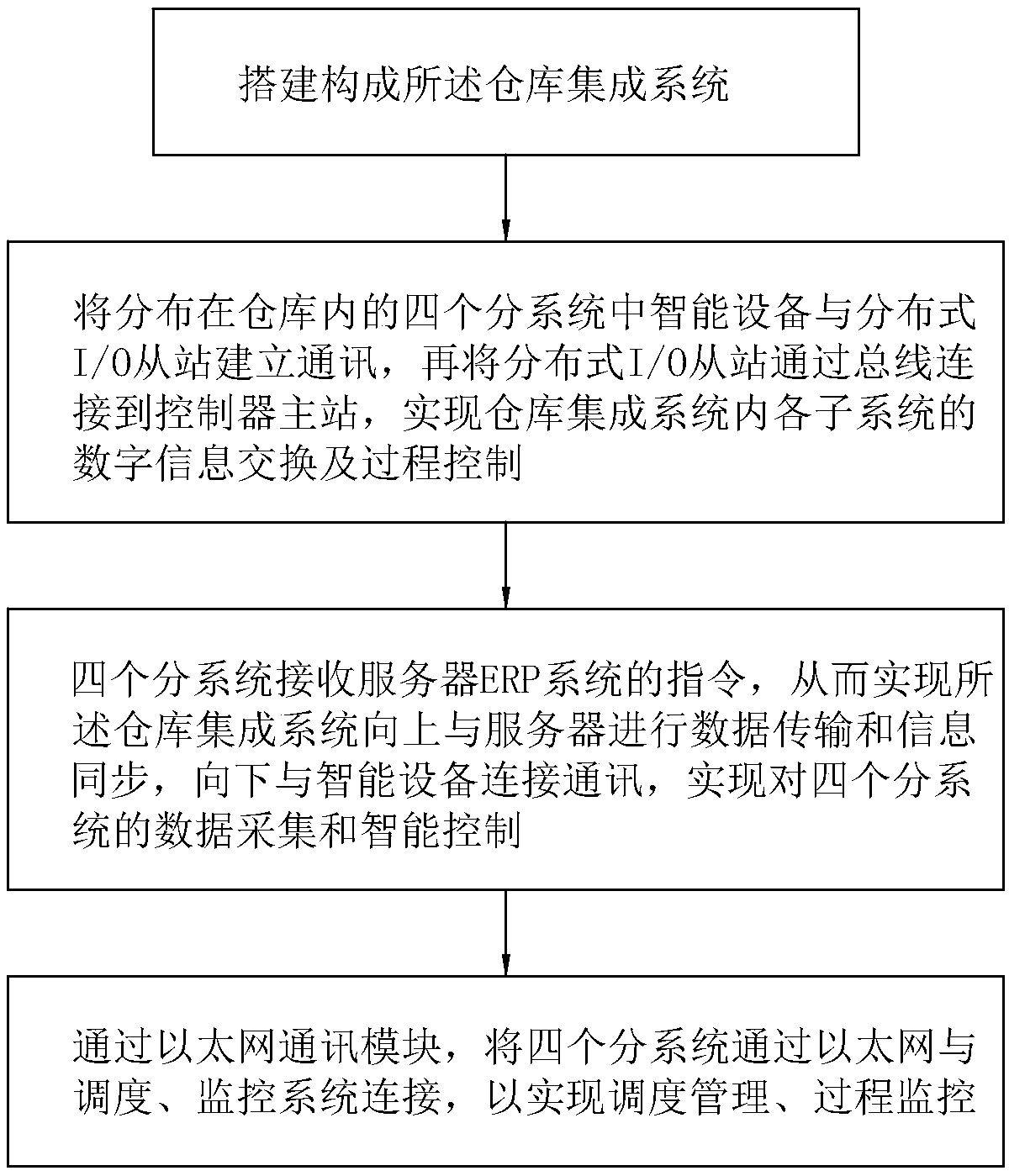

[0045] Such as Figure 1-Figure 6 As shown, this embodiment discloses a smart warehouse integration implementation method, the implementation method includes the following steps:

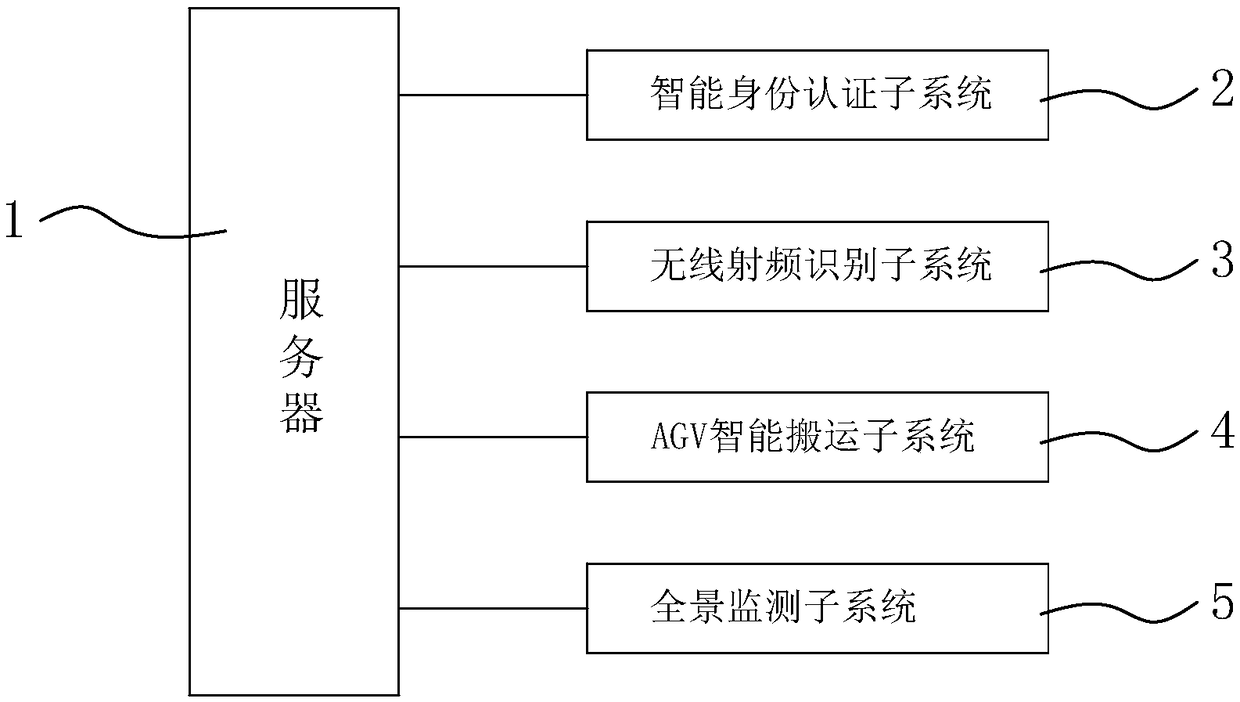

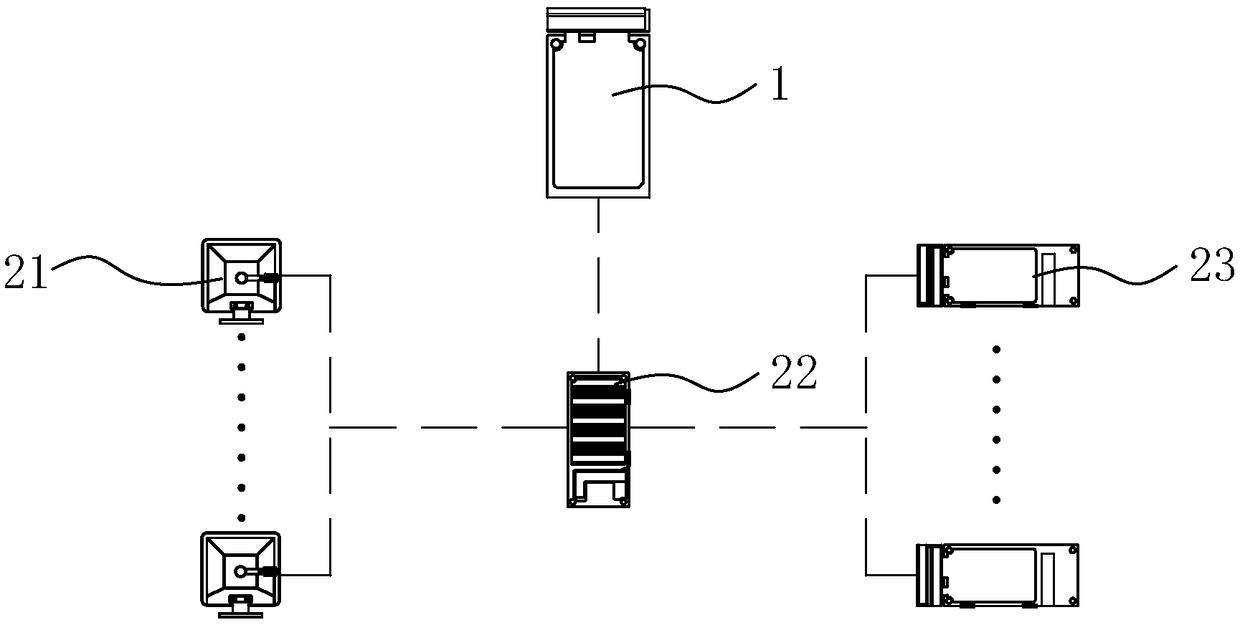

[0046] S1. Build four subsystems of the intelligent identity authentication subsystem, the radio frequency identification subsystem, the AGV intelligent handling subsystem, and the panoramic monitoring subsystem that constitute the warehouse integration system;

[0047] S2. Then establish communication between the intelligent devices in the four sub-systems distributed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com