Memory and method for forming same, semiconductor device

A memory and storage node technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problem of large contact resistance of bit line contact and bit line contact area storage node contact and storage node contact area, preparation high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

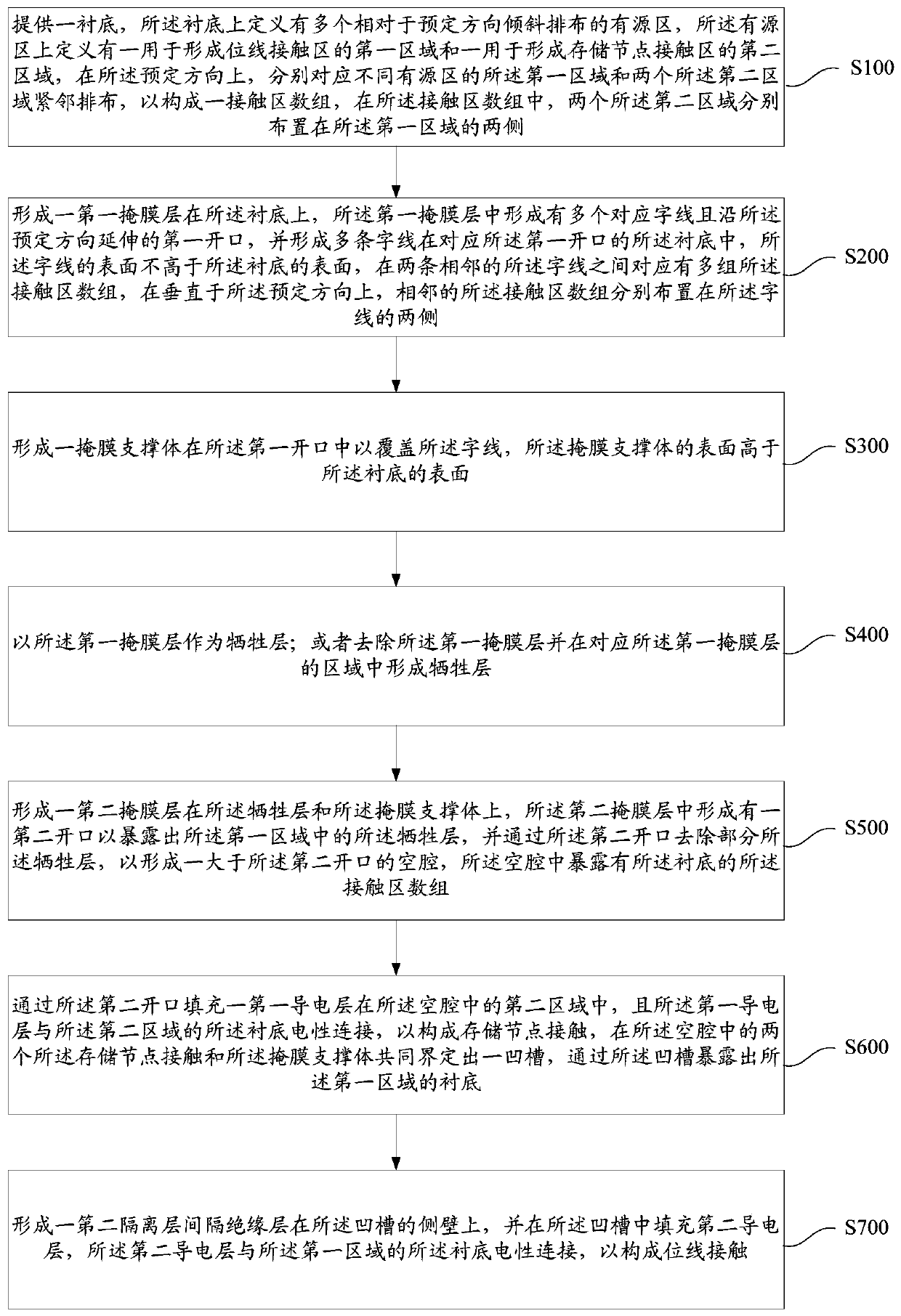

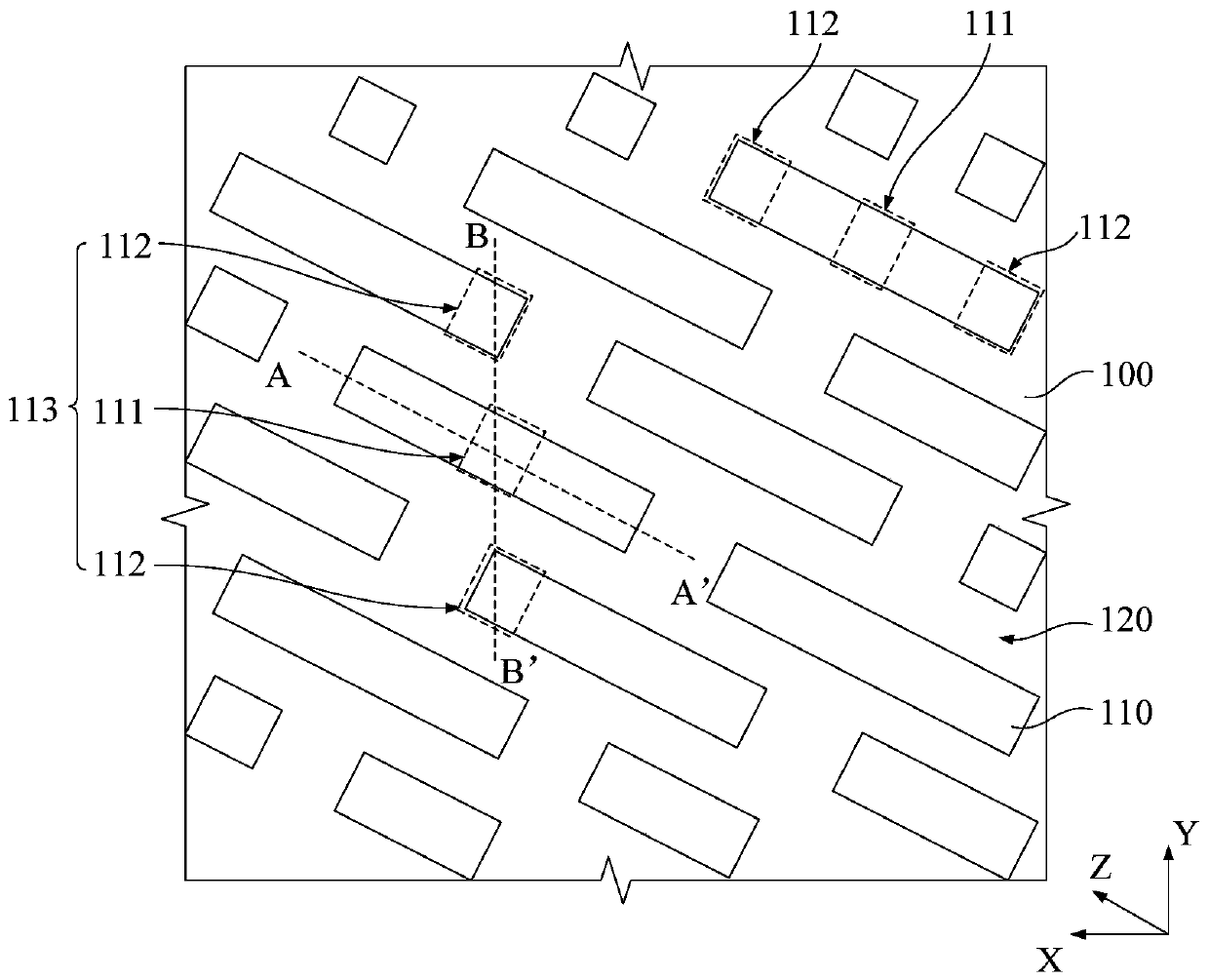

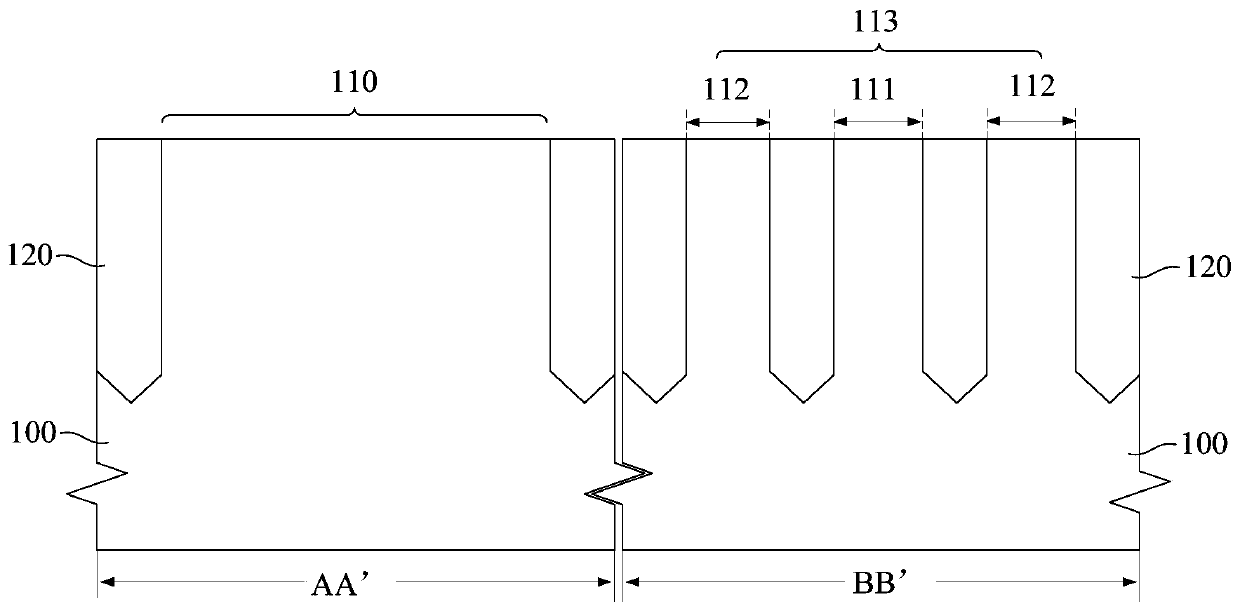

[0120] Figure 2a A top view of the memory forming method in Embodiment 1 of the present invention when step S100 is executed; Figure 2b for Figure 2a The shown cross-sectional views of the memory forming method in Embodiment 1 of the present invention along the directions AA' and BB' when step S100 is executed.

[0121] In step S100, combining Figure 2a and Figure 2b As shown, a substrate 100 is provided, and the substrate 100 is defined with a plurality of active regions 110 arranged obliquely with respect to a predetermined direction, and a first active region 110 is defined on the active region 110 for forming a bit line contact region. A region 111 and a second region 112 for forming a storage node contact region. In the predetermined direction (Y direction), one first region 111 and two second regions 112 respectively corresponding to different active regions 110 are arranged adjacent to each other to form a contact region array 113 . In the array of contact reg...

Embodiment 2

[0185] Figure 9a is a top view of the memory in Embodiment 2 of the present invention, Figure 9b for Figure 9a Shown are cross-sectional views of the memory in Embodiment 2 of the present invention along the directions AA' and BB'. like Figure 9a and Figure 9b As shown, the memory includes:

[0186] A substrate 100, on which are defined a plurality of active regions 110 arranged obliquely (Z direction) relative to a predetermined direction and isolation structures 120 between the active regions, the active regions 110 is formed with a bit line contact region 111a and at least one storage node contact region 112a. In the predetermined direction (Y direction), the bit line contact region 111a and two storage node contact regions corresponding to different active regions 110 are respectively The regions 111b are arranged adjacent to each other to form a contact region array 113a. In the contact region array 113a, the two storage node contact regions 112a are respectivel...

Embodiment 3

[0201] Based on the core idea of the invention, the invention also provides a semiconductor device. Those skilled in the art know that in the field of semiconductors, most devices need to use lead-out terminals to lead out corresponding lead-out areas, so that corresponding functions of the devices can be realized through electrical control. In addition, in semiconductor devices, there are usually multiple lead-out regions. To ensure the performance of the device, different kinds of lead-out regions need to be isolated from each other. Therefore, the present invention provides a semiconductor device based on the core idea of "self-alignment and self-truncation".

[0202] Figure 10a is a top view of the semiconductor device in Embodiment 3 of the present invention, Figure 10b for Figure 10a A schematic diagram of the distribution of the first contact region and the second contact region in the semiconductor device in the third embodiment of the present invention is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com