Silicon heterojunction solar cell and preparation method thereof

A solar cell and silicon heterojunction technology, applied in the field of solar cells, can solve the problems of reduced strength, easy oxidation and corrosion of Cu, and increased resistance, and achieve good oxidation resistance, improved environmental impact resistance and weldability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

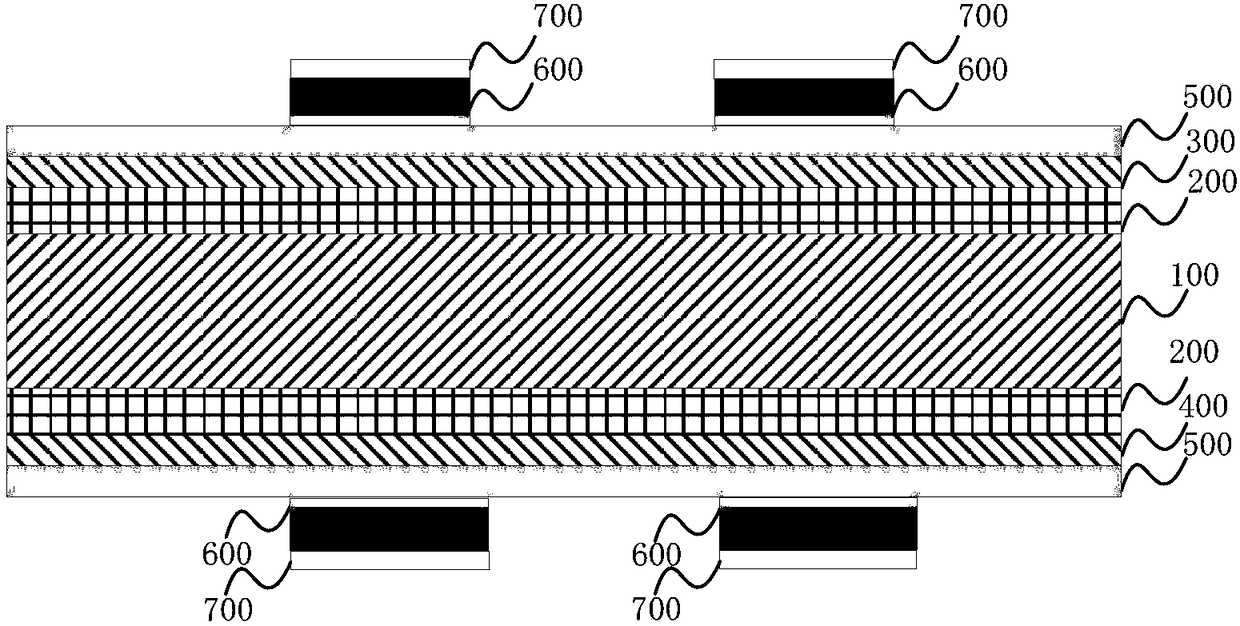

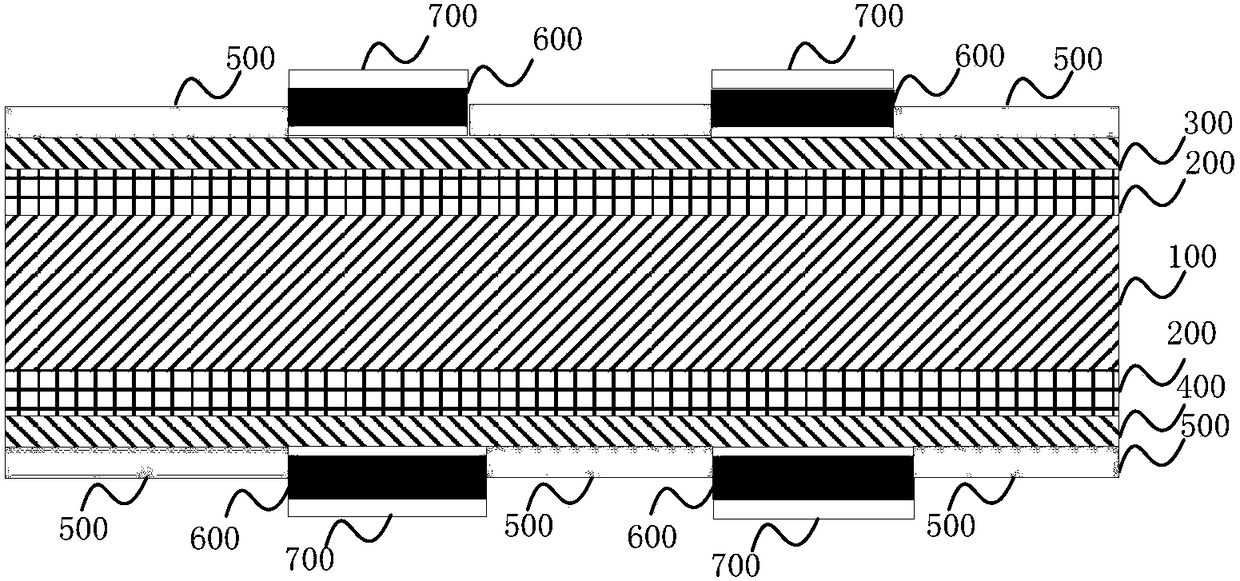

[0113] Prepare the main body layer of silicon heterojunction solar cells according to the following steps:

[0114] (1) An n-type crystalline silicon substrate 100 is provided, the n-type crystalline silicon substrate 100 is cleaned, and textured structures are formed on the upper surface and the lower surface.

[0115] (2) The n-type crystalline silicon substrate is placed in a hydrogen atmosphere for hydrogenation pretreatment.

[0116] (3) Deposit a lightly doped n-type hydrogenated amorphous silicon (a-Si:H) buffer layer on the upper and lower surfaces of the n-type crystalline silicon substrate 100, and the lightly doped n-type hydrogenated amorphous silicon layer uses phosphorus (P ) as the doping element, the doping concentration is 10 14 / cm 3 , with a thickness of 6nm.

[0117] (4) Deposit a heavily doped p-type a-Si:H emitter layer on the surface of the lightly doped n-type hydrogenated amorphous silicon (a-Si:H) buffer layer located on the upper surface, the heav...

Embodiment 2

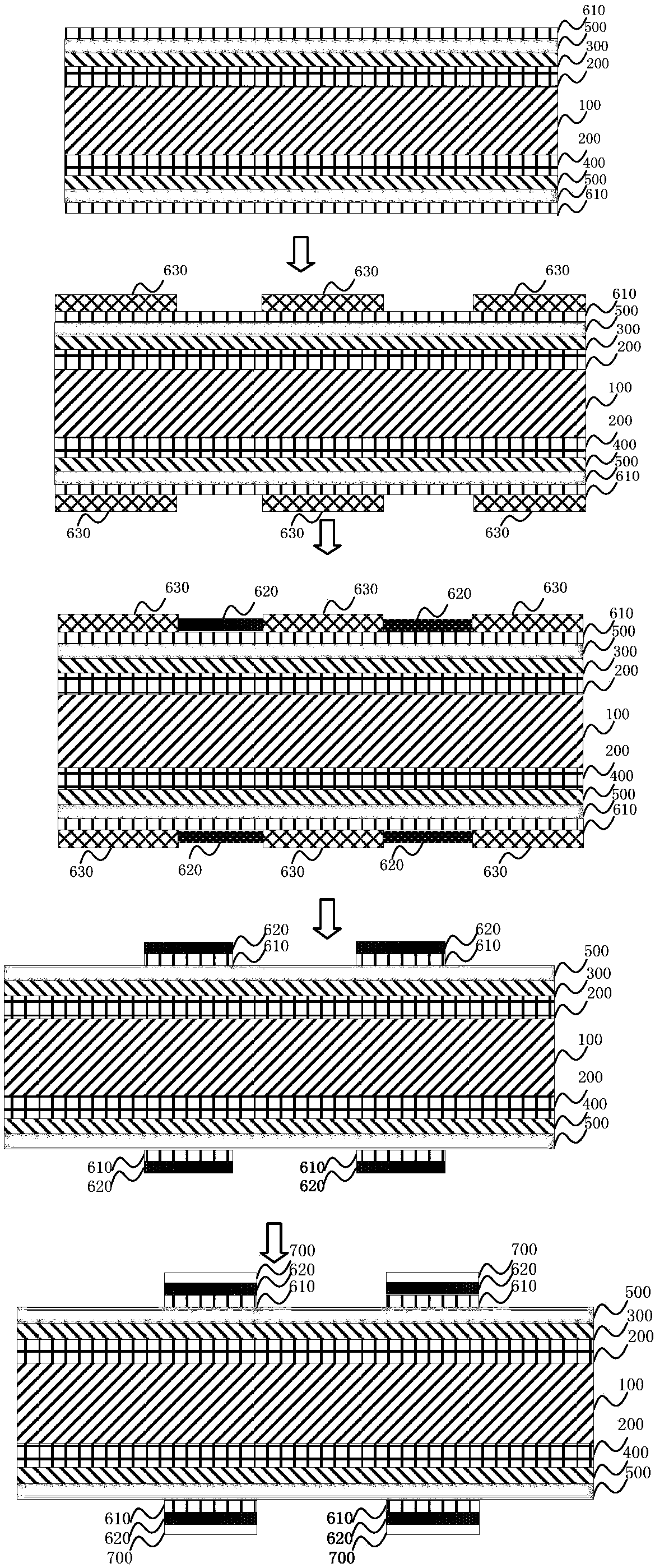

[0122] refer to image 3 , the steps of preparing a silicon heterojunction solar cell using the method for preparing a solar cell according to an embodiment of the present invention are as follows:

[0123] (1) A Ti-Al alloy transition layer 610 with a thickness of 20 nm was formed on the surface of the transparent conductive oxide of the main body layer prepared in Example 1 by magnetron sputtering.

[0124] (2) Form a photoresist film 630 on the surface of the Ti-Al alloy transition layer 610 by spin coating, and heat and dry to form a dry film.

[0125] (3) using a mask plate with an electrode pattern and a photolithography method to open holes at the position where the predetermined electrode pattern is formed on the dry film.

[0126] (4) Form a Cu metal layer 620 with a thickness of 30 μm at the opening of the dry film by electroplating. The dry film is electrically insulated, so the part outside the opening will not be plated with Cu.

[0127] (5) Remove the dry film ...

Embodiment 3

[0131] refer to Figure 4 , the steps of preparing a silicon heterojunction solar cell using the method for preparing a solar cell according to an embodiment of the present invention are as follows:

[0132] (1) A Ti-Al alloy transition layer 610 with a thickness of 20 nm was formed on the surface of the transparent conductive oxide of the main body layer prepared in Example 1 by magnetron sputtering.

[0133] (2) Form a photoresist film 630 on the surface of the Ti-Al alloy transition layer 610 by spin coating, and heat and dry to form a dry film.

[0134] (3) using a mask plate with an electrode pattern and a photolithography method to open holes at the position where the predetermined electrode pattern is formed on the dry film.

[0135] (4) Form a Cu metal layer 620 with a thickness of 30 μm at the opening of the dry film by electroplating. The dry film is electrically insulated, so the part outside the opening will not be plated with Cu.

[0136] (5) The second electrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com