Converter control circuit, application and control method thereof

A converter control and control circuit technology, applied in control/regulation systems, DC power input conversion to DC power output, instruments, etc., can solve the problems of increased loss, large turn-on loss, low efficiency, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to better understand the design concept of the control circuit of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

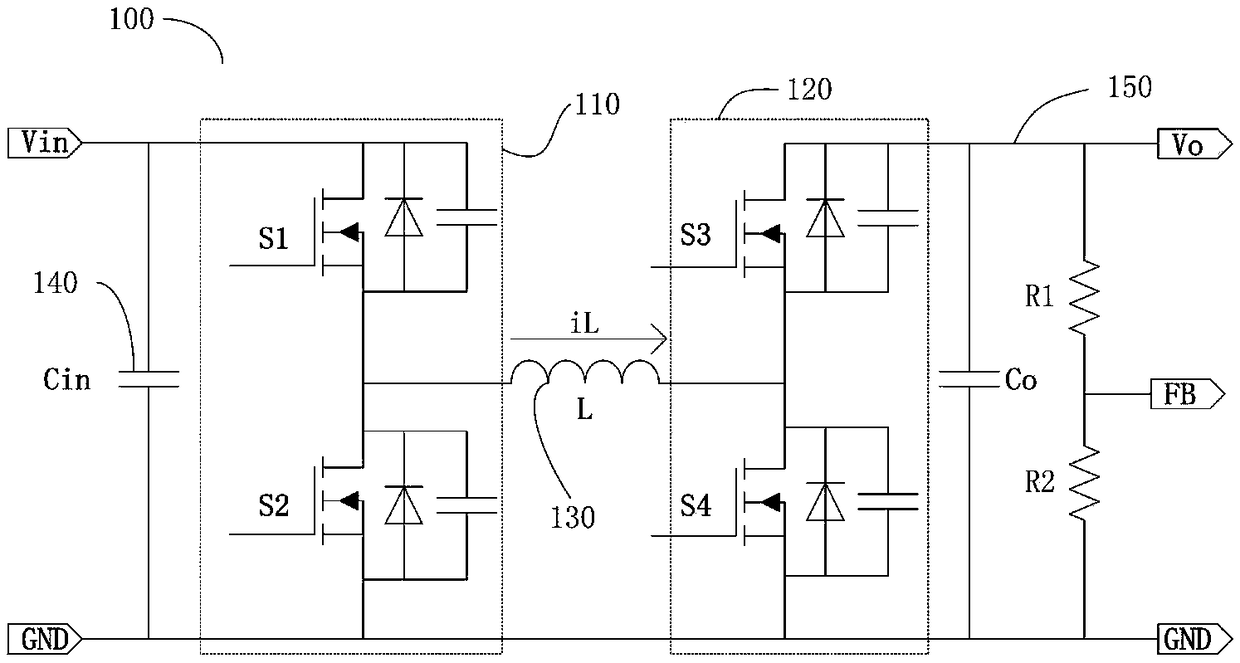

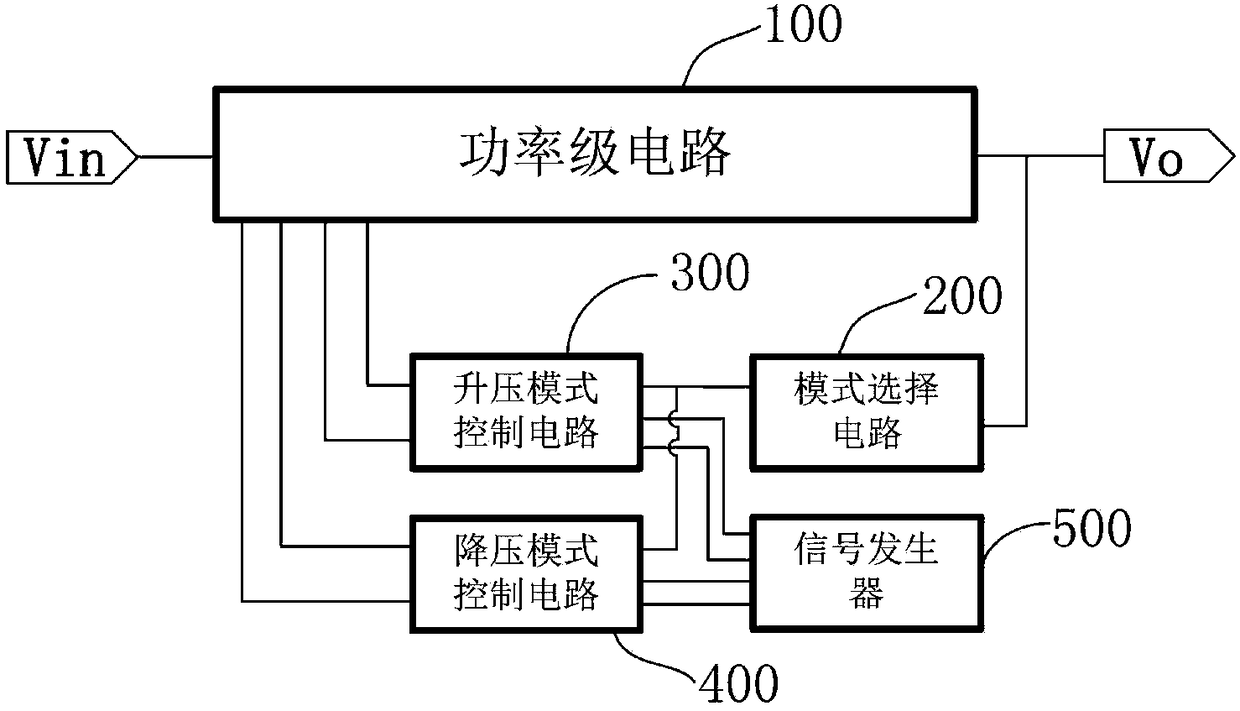

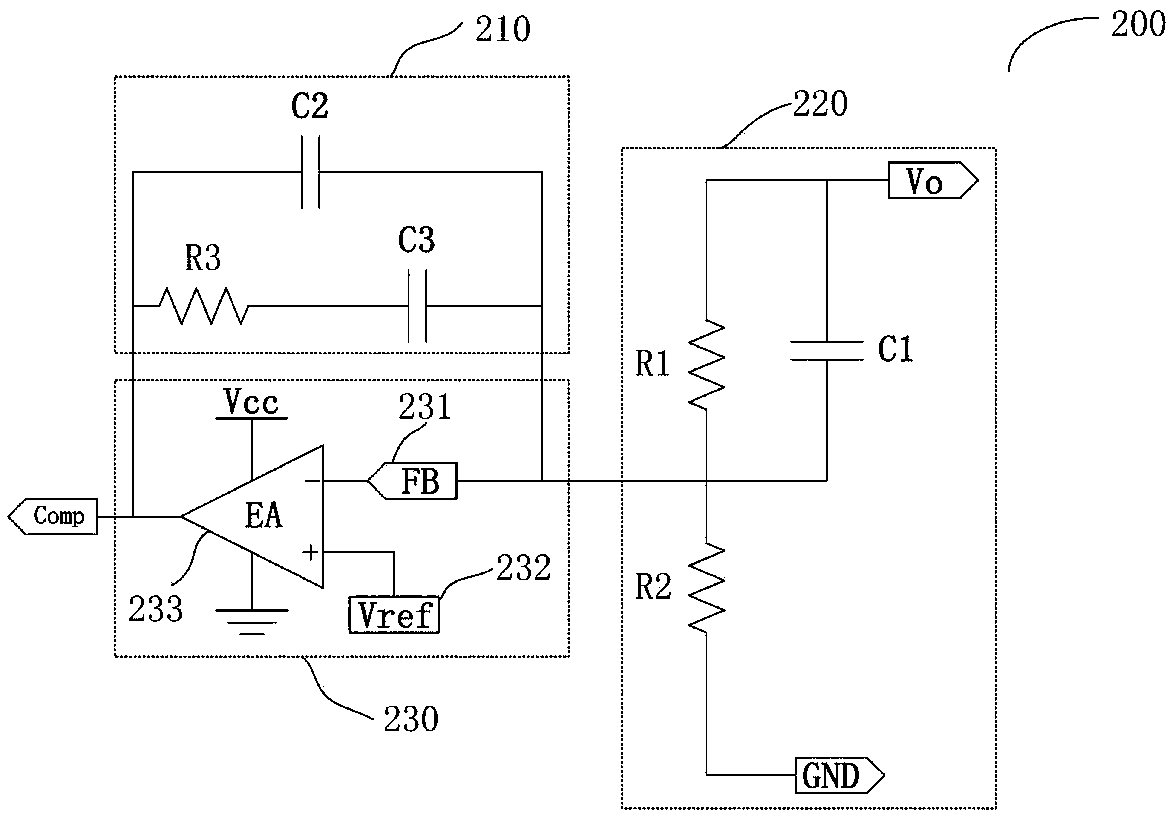

[0054] refer to figure 2 , is a schematic structural diagram of the control circuit of the boost-buck converter of the present invention, the boost-buck converter includes a power stage circuit 100, and its control circuit includes a mode selection circuit 200, a boost mode control circuit 300, a buck mode control circuit 400 and Signal generator 500.

[0055]The power stage circuit 100 is used to convert the input voltage Vin into a desired voltage value and output it, the mode selection circuit 200 is used to select the working mode required by the boost-buck converter according to the output voltage, and the boost mode control circuit 300 works When the input voltage is lower than the output voltage, it is used to increase the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com