Three component composition for the manufacture of polyurethane cementitious hybrid flooring or coating with improved surface gloss

A composition and three-component technology, applied in polyurea/polyurethane coatings, coatings, solid waste management, etc., can solve problems such as difficult to clean, non-glossy, dull surface, etc., and achieve an easy-to-clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0136] Reference Example

[0137] The reference composition for floor covering applications is used or manufactured as follows.

[0138] Reference composition R-1

[0139] The reference composition R-1 not according to the invention is a three-component polyurethane cement-based hybrid floor covering composition that uses component (A) not according to the invention (lack of polyol P1c).

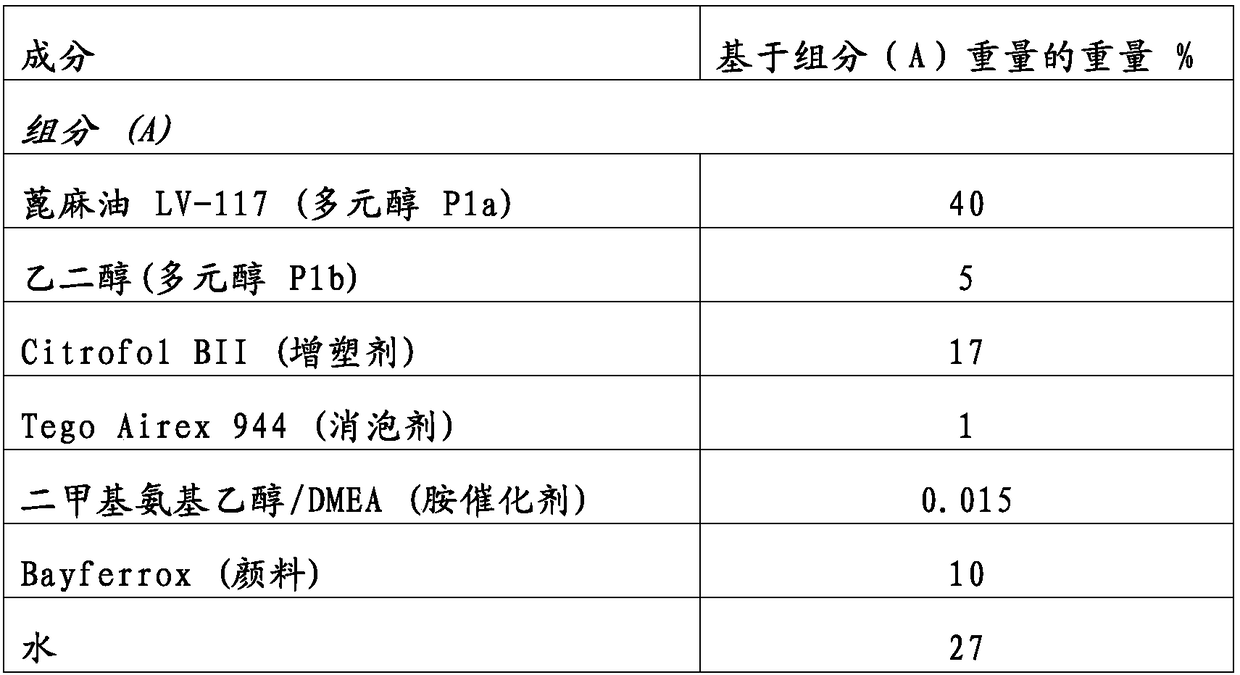

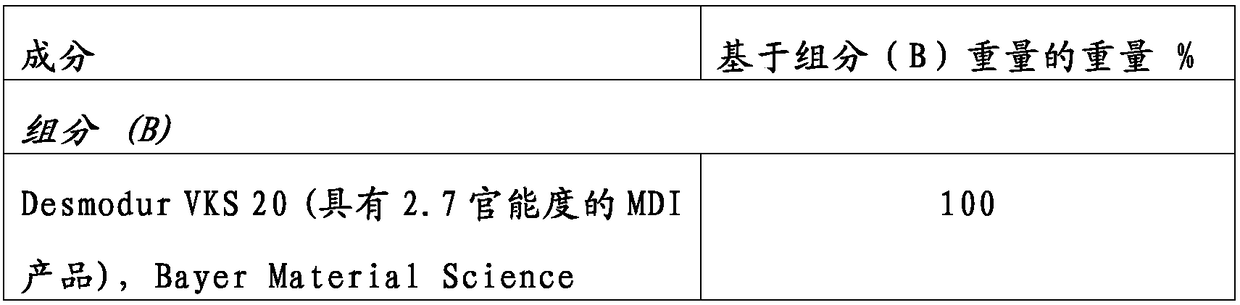

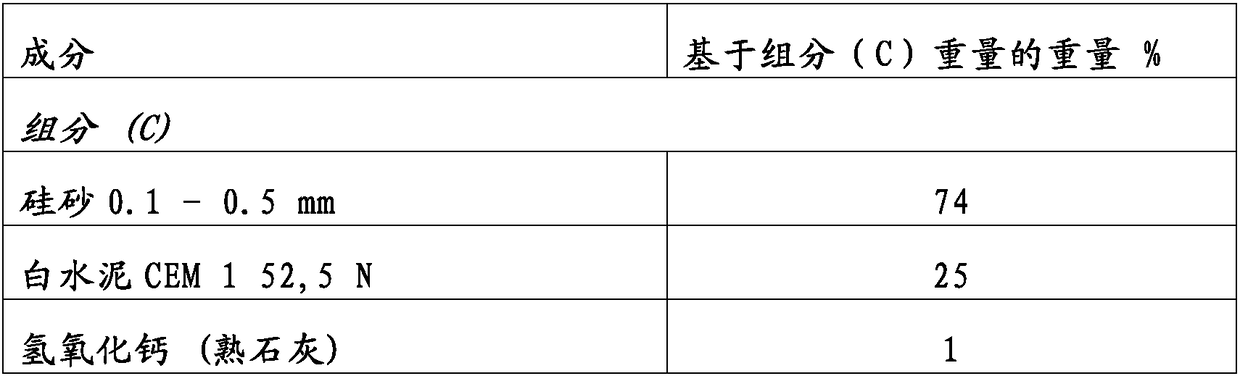

[0140] The composition of component (A), component (B) and component (C) is shown below.

[0141] The ingredients indicated below are mixed to form component (A), component (B) or component C, respectively. The amount given is in mass ratio.

[0142]

[0143]

[0144]

[0145] Composition mixture

[0146] The components (A), (B), and (C) are mixed in a weight ratio to obtain a mixture as shown below, for example, the weight ratio used is about 16.5, 16.5, and 67. Based on the total weight of the mixture A+B+C, the parts of each ingredient are given in weight %.

[0147] A+B+C(%)

[0148]

[0149] Fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com