Method for determining contents of TMG by utilizing gas chromatography

A technology of gas chromatography and gas chromatographic analysis, which is applied in the field of determining TMG content by gas chromatography, and achieves the effects of simple method, high sensitivity and accurate method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

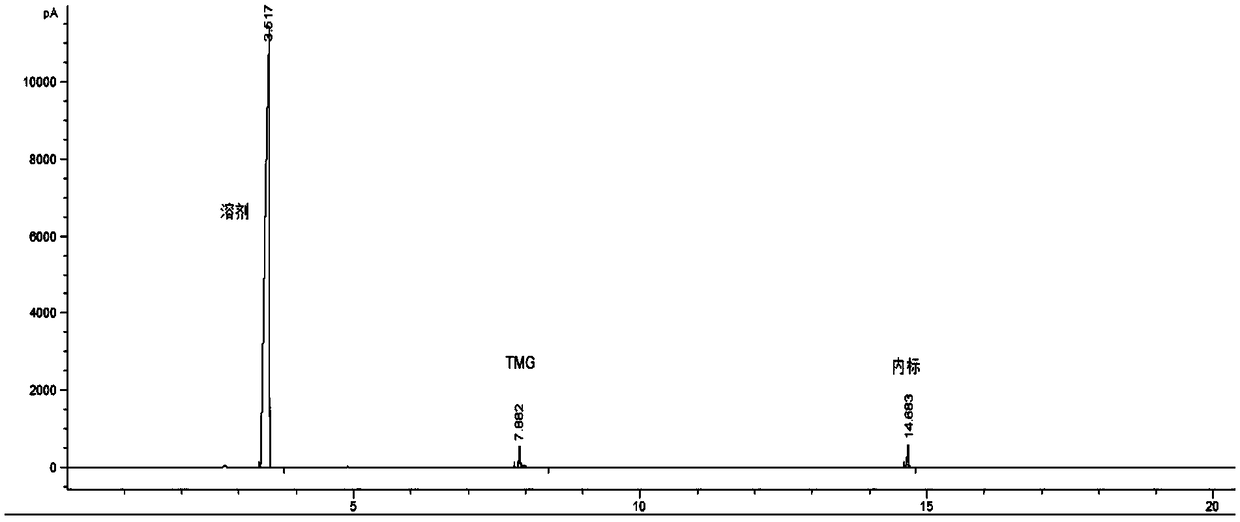

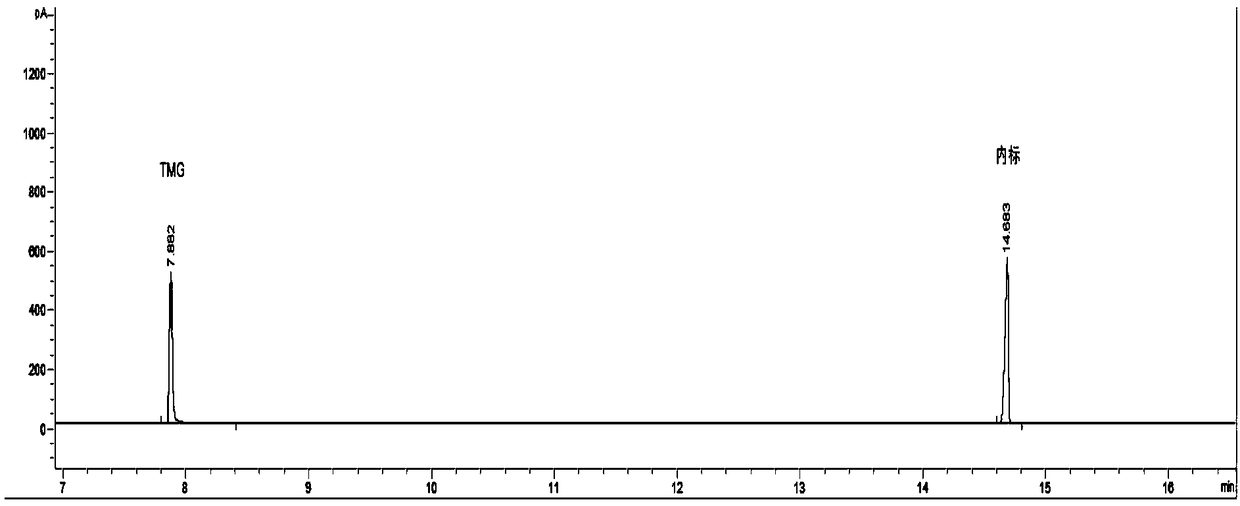

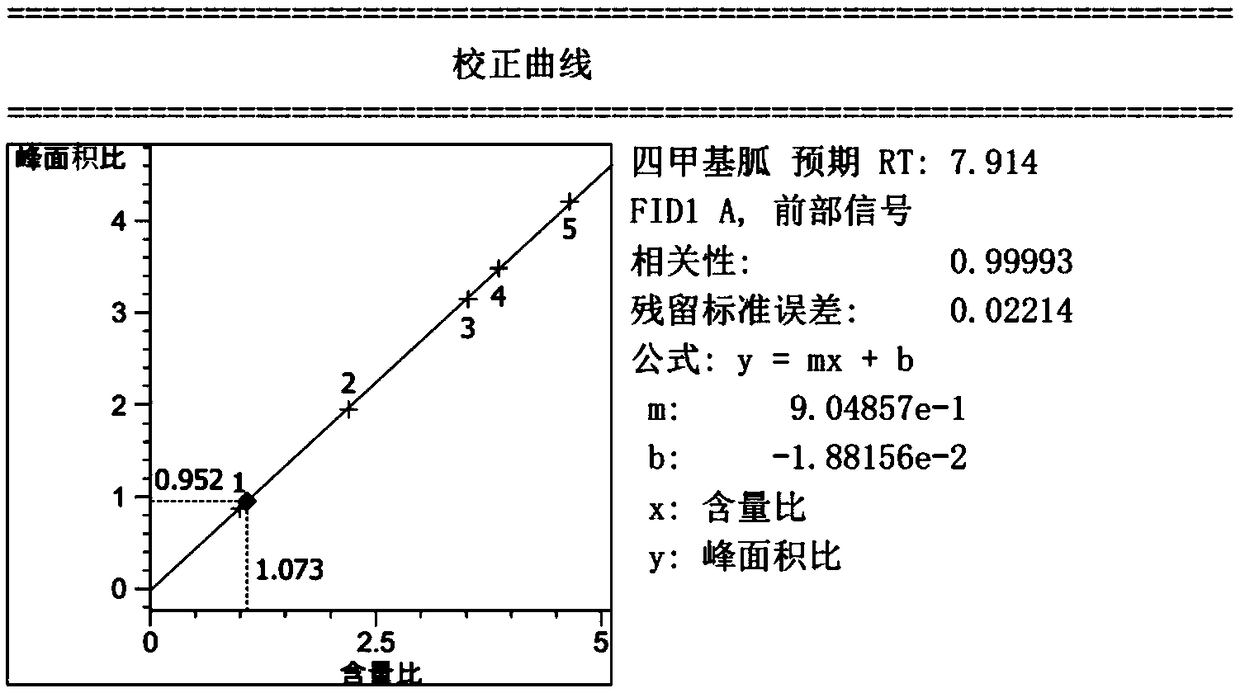

[0067] There is a batch of TMG samples with an unknown concentration, about 10%, which need to be determined. Gas chromatography is used for detection and internal standard percentage method for quantitative analysis. The specific steps include:

[0068] 1. Prepare TMG standard solution: Accurately weigh 0.05g, 0.1g, 0.15g, 0.2g, 0.25g (accurate to 0.0001) of TMG standard samples respectively in 10mL volumetric flasks, add internal standard dimethyl phthalate respectively Esters 0.05g, dilute to the mark with dimethyl carbonate to obtain standard solutions I, II, III, IV, V, the concentrations are 5000mg / L, 10000mg / L, 15000mg / L, 20000mg / L, 25000mg / L respectively ;

[0069] 2. Prepare TMG sample solution: According to the approximate content range of TMG in the sample, accurately weigh an appropriate amount of sample (accurate to 0.0001g), such as 0.5g in a 10mL volumetric flask, add 0.05g of internal standard dimethyl phthalate , dimethyl carbonate to the scale, to obtain a T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com