Sonos device manufacturing process method

A manufacturing process and device technology, applied in the field of SONOS device manufacturing process, can solve problems such as being susceptible to interference, selection tubes and storage tubes do not share source and drain regions, etc., to reduce area, realize self-aligned etching, and reduce selection. tube effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

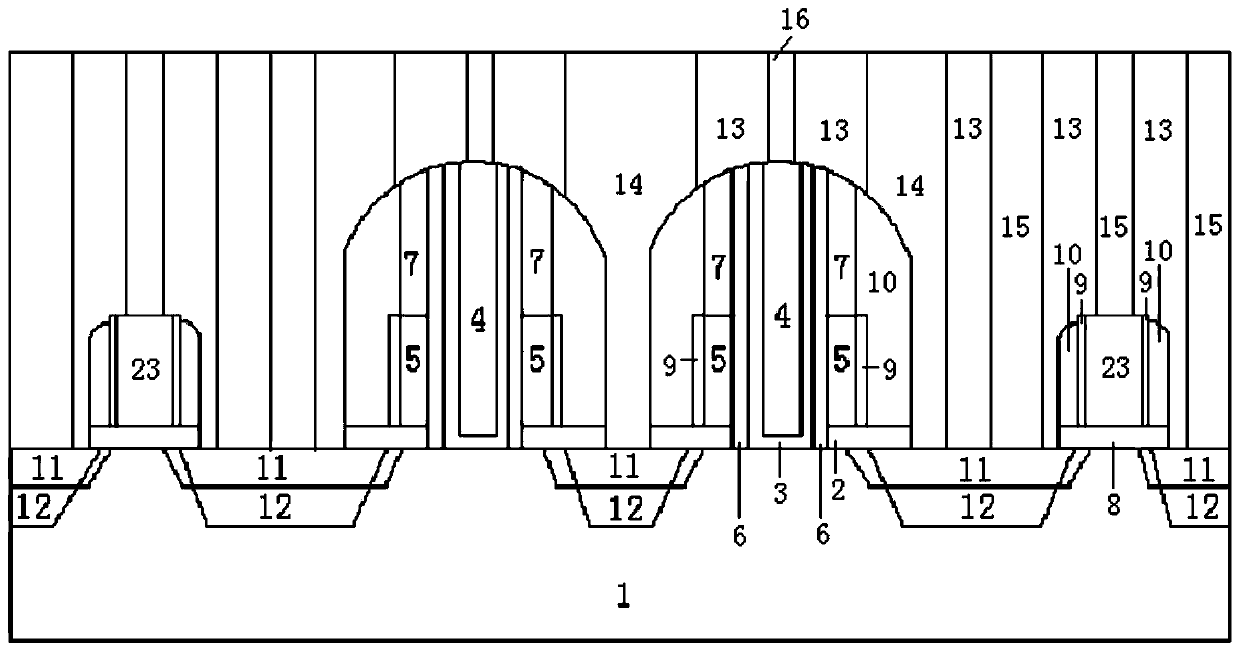

[0024] Described self-aligned SONOS device manufacture process method is in the following embodiment, implementation process is as follows:

[0025] Step 1, see Figure 4 A first oxide layer 17 is formed on the upper end of the P-type substrate 1, and the oxide layer 17 is used to finally form the gate oxide layer 8 of the transistor in the logic region and the gate oxide layer 2 of the selection transistor. A first polysilicon layer 18 and a first silicon nitride layer 22 are sequentially deposited on the first oxide layer 17, and the first polysilicon layer 18 is used to form the select transistor polysilicon gate 5 and the logic region transistor polysilicon Grid 23. The first silicon nitride layer 22 is used as a reserved layer of the CMP (chemical mechanical polishing) stop layer, and its deposited thickness is

[0026] Step 2, see Figure 5 , the photolithography is opened, the first silicon nitride layer 22 is etched, and the first polysilicon layer 18 is implanted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com