A kind of plastic film recovery mechanism and recovery method

A recovery mechanism and recovery method technology, applied in the field of agricultural machinery, can solve the problems of film cutting position deviation, affecting the recovery efficiency of plastic film, and the moving speed of the chain plate is not as good as that of the rotor, so as to achieve stable lateral support, improve the recovery efficiency of residual film, The effect of saving the cost of machinery manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

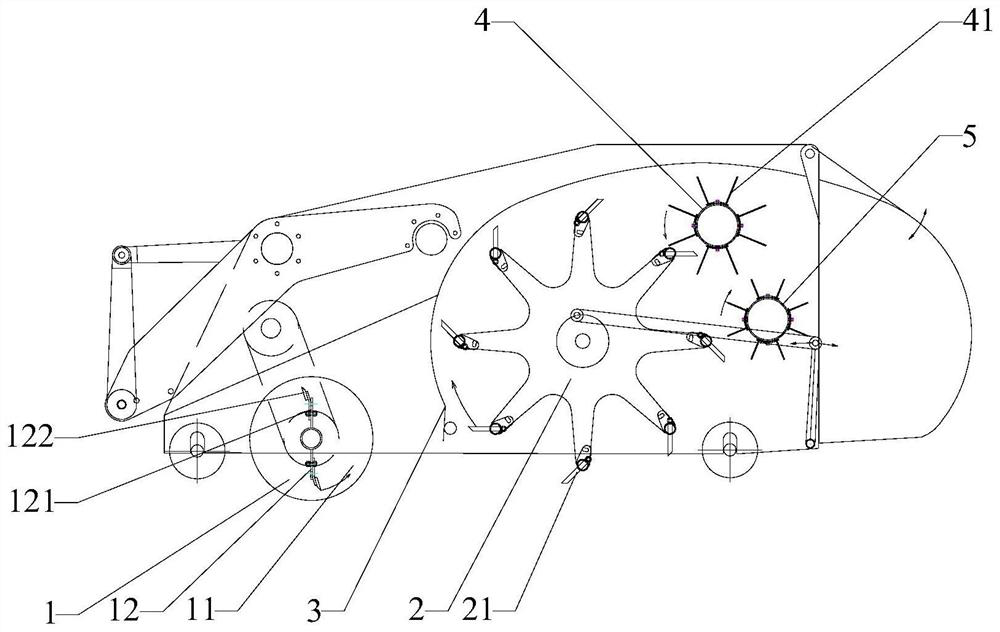

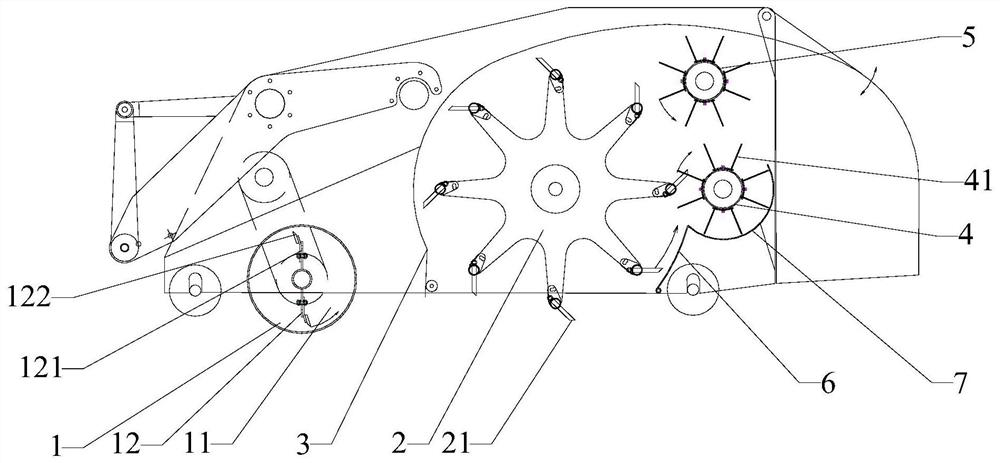

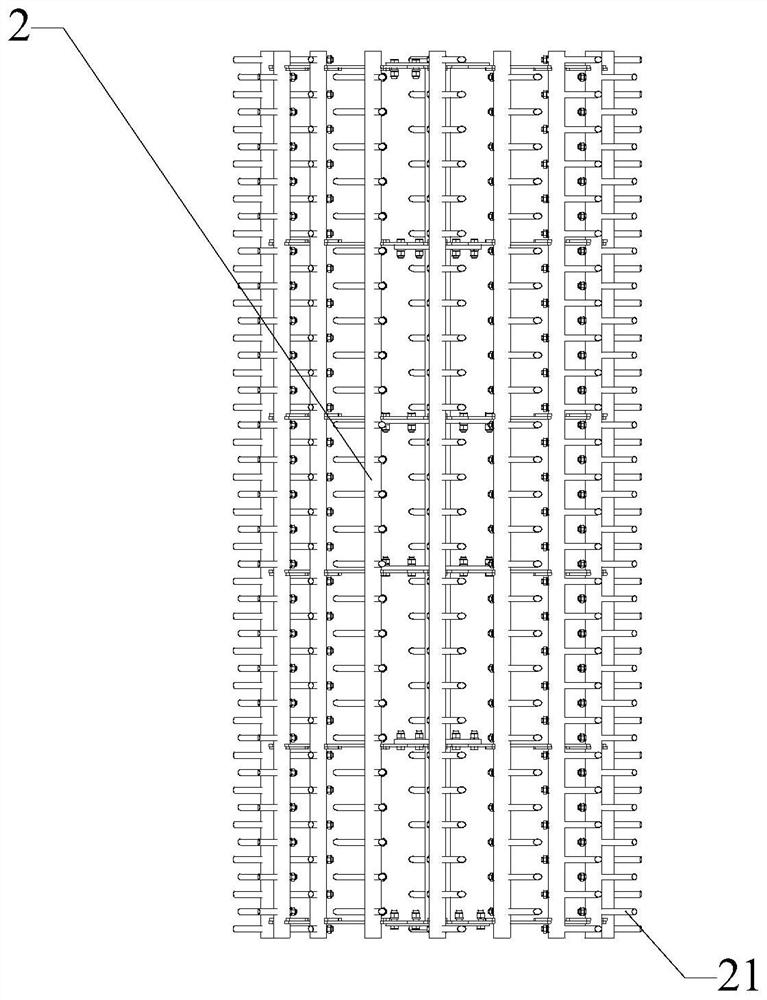

[0075] A film recovery mechanism, comprising a film-lifting and splitting rotor 1 and a pin-type film-picking rotor 2 arranged in sequence backward from the forward direction of a frame; the film-raising and splitting rotor 1 includes a plurality of discs coaxially arranged with the splitting rotor Shape film cutting knife 11 and a plurality of plate-shaped film cutting knives 12 perpendicular to disc-shaped film cutting knife 11; Described nail type film picking rotor 2 includes many rows of tooth nails 21 distributed on the outer edge of the film picking rotor; The outer edge linear velocity of the film splitting rotor 1 is greater than the forward speed of the frame.

[0076] The plate-shaped film removing knife 12 includes a mounting plate 121 arranged along the normal direction of the wheel shaft and a film removing knife body 122 fixed on the mounting plate 121 . The plate-shaped film-lifting knife 12 is inclined 1-45 degrees to the rotation direction along the normal di...

Embodiment 2

[0081] A film recovery mechanism, comprising a film-lifting and splitting rotor 1 and a pin-type film-picking rotor 2 arranged in sequence backward from the forward direction of a frame; the film-raising and splitting rotor 1 includes a plurality of discs coaxially arranged with the splitting rotor Shape film cutting knife 11 and a plurality of plate-shaped film cutting knives 12 perpendicular to disc-shaped film cutting knife 11; Described nail type film picking rotor 2 includes many rows of tooth nails 21 distributed on the outer edge of the film picking rotor; The outer edge linear velocity of the film splitting rotor 1 is greater than the forward speed of the frame.

[0082] The plate-shaped film removing knife 12 includes a mounting plate 121 arranged along the normal direction of the wheel shaft and a film removing knife body 122 fixed on the mounting plate 121 . The plate-shaped film-lifting knife 12 is inclined 1-45 degrees to the rotation direction along the normal di...

Embodiment 3

[0087] A kind of plastic film recovery method, comprises the following steps:

[0088] S1: The power drive device drives the frame to advance towards the area to be operated;

[0089] S2: The cutter group of rotor 1 cuts the surface film into blocks and throws the block film and soil to the rear;

[0090] S21: The earth retaining plate 3 is hit by the soil together with the massive plastic film, the soil is broken, and after falling, the plastic film is located on the soil surface;

[0091] S3: The pin-type film-picking rotor 2 rotates in the opposite direction to the film-lifting and dividing rotor 1, and picks up the film along the retaining plate 3 and transports it backward;

[0092] S4: The comb 41 of the comb-type film-removing rotor 4 brushes out the plastic film on the tooth nail 21; with the cooperation of the comb-type brush 41-type film-guiding and soil-clearing rotor 5, the plastic film is transported to the film collecting bucket.

[0093] The limit speed on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com