Non-woven fabric used for automobile air-conditioning filter cores

A technology for automotive air conditioners and non-woven fabrics, which is used in filtration and separation, membrane filters, vehicle components, etc., can solve problems such as affecting the health of passengers, breeding a large number of bacteria, and difficult to remove bacteria, so as to reduce bacterial growth and reduce The effect of harming the body of passengers and not easy to adhere to dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

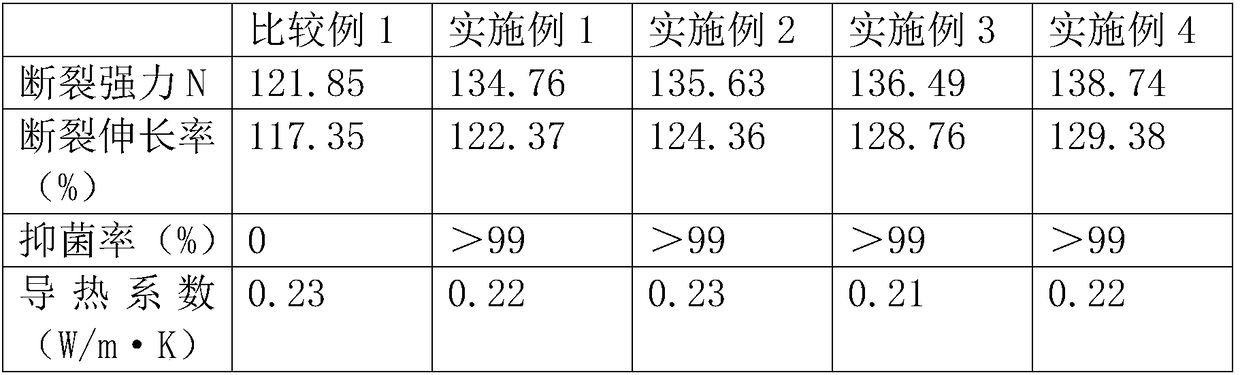

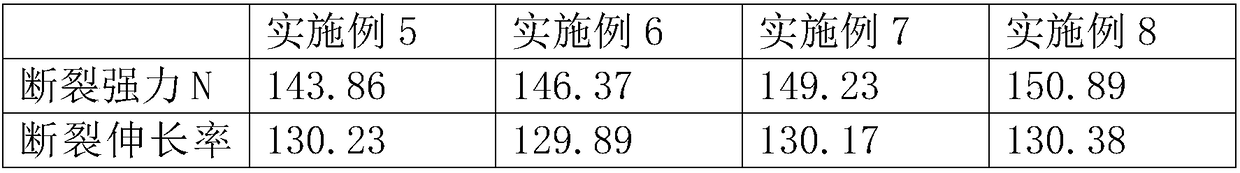

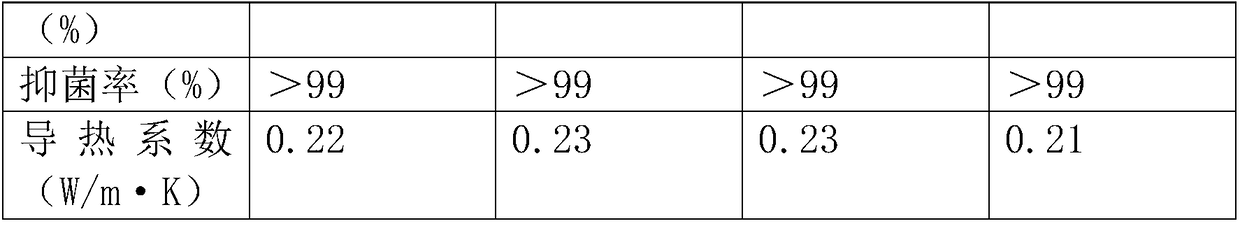

Examples

Embodiment 1

[0037] A non-woven fabric for automotive air-conditioning filters, comprising the following components in parts by mass:

[0038] 25 parts of bamboo fiber; 20 parts of lotus fiber; 20 parts of polyurethane fiber; 15 parts of titanium dioxide fiber.

[0039] Bamboo fiber is the common bamboo fiber in this area;

[0040] Lotus fiber is common lotus fiber in this field;

[0041] The polyurethane fiber is a common thermoplastic polyether polyurethane material in the field. Specifically, the polyurethane fiber is composed of polyethylene glycol: MDI: BDO = 1: 1.1: 0.1, wherein the molecular weight of polyethylene glycol is 4000;

[0042] Titanium dioxide is a common nano-titanium dioxide fiber in the field.

[0043] The preparation method of non-woven fabric is as follows;

[0044] (1) Weighing, as follows:

[0045] Weigh bamboo fiber, lotus fiber, polyurethane fiber and titanium dioxide fiber respectively according to the formula.

[0046] (2) Grinding, specifically as follow...

Embodiment 2

[0069] The difference with embodiment 1 is:

[0070] The non-woven fabric includes the following components in parts by mass:

[0071] 27 parts of bamboo fiber; 22 parts of lotus fiber; 22 parts of polyurethane fiber; 17 parts of titanium dioxide fiber.

Embodiment 3

[0073] The difference with embodiment 1 is:

[0074] The non-woven fabric includes the following components in parts by mass:

[0075] 29 parts of bamboo fiber; 22 parts of lotus fiber; 24 parts of polyurethane fiber; 17 parts of titanium dioxide fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com