Preparation method of black gold glaze, black gold glaze and method for preparing ceramic product from black gold glaze

A technology for ceramic products and black gold, applied in the preparation of black gold glaze, black gold glaze, preparation of black gold glaze and ceramic field, can solve the problems of insufficient product strength, high firing temperature, waste of resources, etc., to improve transparency, improve strength, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

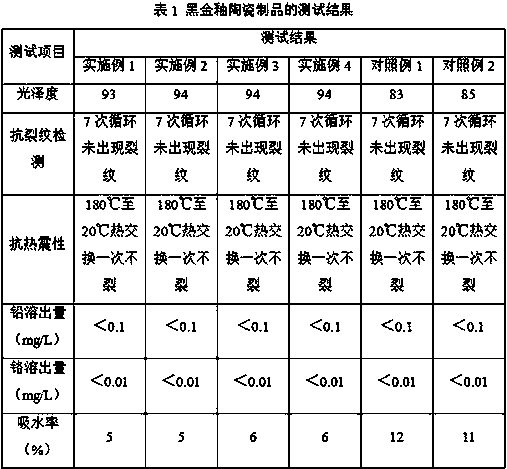

Examples

Embodiment 1

[0041] The black gold glaze includes a bottom glaze and a surface glaze, wherein the bottom glaze includes the following components in parts by mass: 30 parts of Longyan kaolin, 10 parts of talc, 5 parts of serpentine, 6 parts of iron oxide, and 11 parts of cerium sulfide share;

[0042] The surface glaze includes the following components in parts by mass: 23 parts of Longyan kaolin, 6 parts of monazite, 5 parts of alumina, 10 parts of praseodymium oxide, 9 parts of methylcellulose, 6 parts of calcium oxide, and 6 parts of calcite .

[0043] The preparation method of described black gold glaze, comprises the steps:

[0044] Step one, broken:

[0045] According to the number of parts by mass, the following components of the bottom glaze are uniformly mixed and crushed to obtain the bottom glaze broken material: Longyan kaolin, talc, serpentine, iron oxide and cerium sulfide;

[0046] According to the number of parts by mass, the following components of the surface glaze are ...

Embodiment 2

[0066] The black gold glaze includes a bottom glaze and a surface glaze, wherein the bottom glaze includes the following components in parts by mass: 31 parts of Longyan kaolin, 11 parts of talc, 6 parts of serpentine, 12 parts of cerium sulfide, and 7 parts of iron oxide share;

[0067] The surface glaze includes the following components in parts by mass: 24 parts of Longyan kaolin, 7 parts of monazite, 6 parts of alumina, 11 parts of praseodymium oxide, 10 parts of methylcellulose, 7 parts of calcium oxide, and 7 parts of calcite .

[0068] The preparation method of described black gold glaze, comprises the steps:

[0069] Step one, broken:

[0070] According to the number of parts by mass, the following components of the bottom glaze are uniformly mixed and crushed to obtain the bottom glaze broken material: Longyan kaolin, talc, serpentine, iron oxide and cerium sulfide;

[0071] According to the number of parts by mass, the following components of the surface glaze are...

Embodiment 3

[0091] The black gold glaze comprises a bottom glaze and a surface glaze, wherein the bottom glaze includes the following components in parts by mass: 33 parts of Longyan kaolin, 12 parts of talc, 7 parts of serpentine, 8 parts of iron oxide, and 13 parts of cerium sulfide share;

[0092] The surface glaze includes the following components in parts by mass: 25 parts of Longyan kaolin, 8 parts of monazite, 7 parts of alumina, 13 parts of praseodymium oxide, 11 parts of methylcellulose, 8 parts of calcium oxide, and 8 parts of calcite .

[0093] The preparation method of described black gold glaze, comprises the steps:

[0094] Step one, broken:

[0095] According to the number of parts by mass, the following components of the bottom glaze are uniformly mixed and crushed to obtain the bottom glaze broken material: Longyan kaolin, talc, serpentine, iron oxide and cerium sulfide;

[0096] According to the number of parts by mass, the following components of the surface glaze ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com