Method for safely utilizing soil in industrial site

A soil and site technology, applied in the field of safe utilization of industrial site soil, to achieve the effects of simple curing process, enhanced strength and reliability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

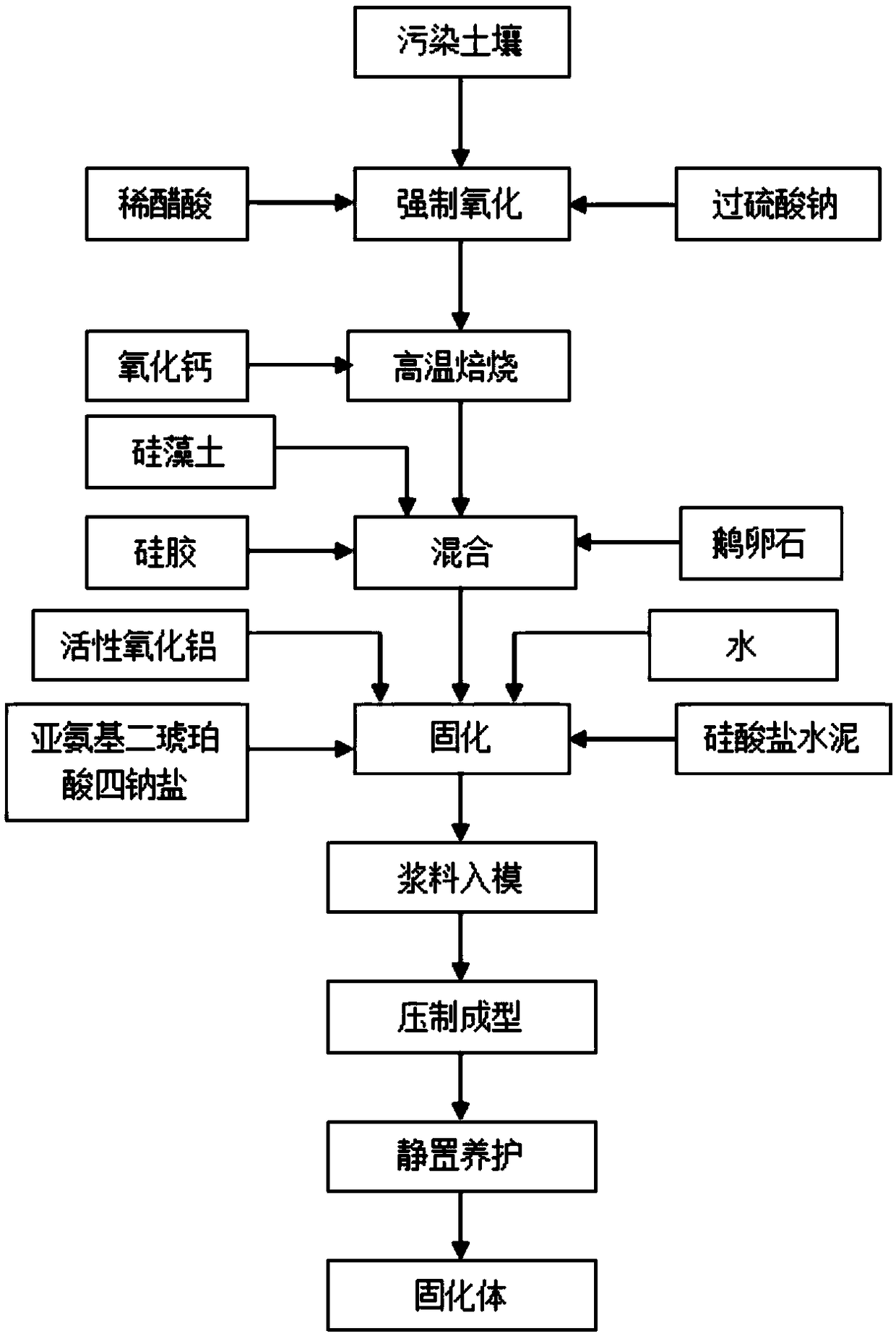

Image

Examples

Embodiment 1

[0028] Take the soil that is heavily polluted by various heavy metals and various toxic organic compounds in the industrial site, remove sand and gravel, add an appropriate amount of dilute acetic acid solution and sodium persulfate powder accounting for 2% of the soil mass for stirring treatment, sodium persulfate produces sulfate Free radicals and sulfate radicals degrade the high-ring PAHs in the soil into low-ring and low-toxic substances; add a certain amount of calcium oxide powder to the treated soil and mix it, then send it to the muffle furnace for high-temperature roasting, and the temperature is controlled at 600°C to obtain soil from which organic pollutants have been removed; add a certain mass proportion of diatomite with a particle size of 1 to 5 mm, a certain mass proportion of silica gel powder with a particle size of 1 to 5 mm and a certain mass proportion to the soil from which organic pollutants have been removed. The proportion of pebbles with a particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com