A kind of preparation method of biological source dipeptidyl peptidase-IV inhibitor

A dipeptidyl peptidase and inhibitor technology, applied in the field of protein extraction, can solve problems such as low resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

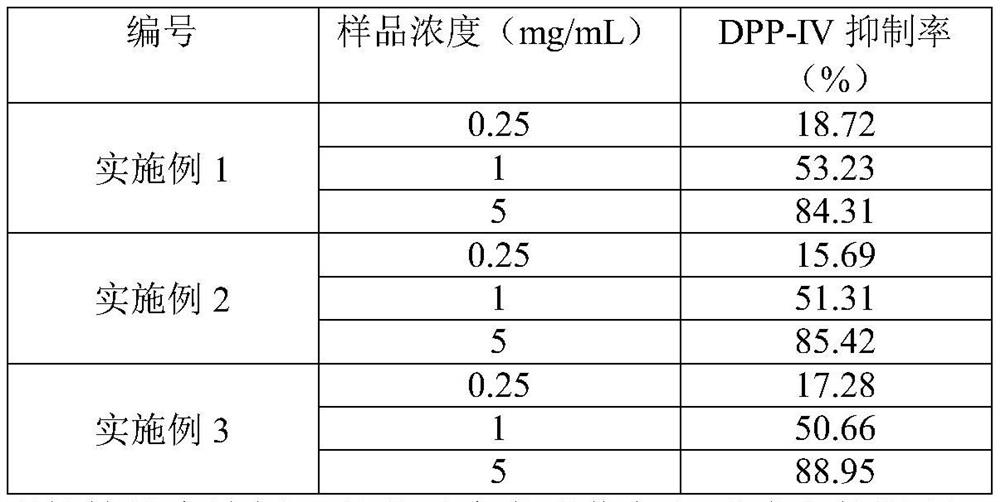

Examples

Embodiment 1

[0031] (1) Pretreatment of Japanese yellow croaker skin:

[0032] (a) washing the fish skin, freeze-drying, and pulverizing to a particle size of 25-50 μm to obtain frozen fish skin powder;

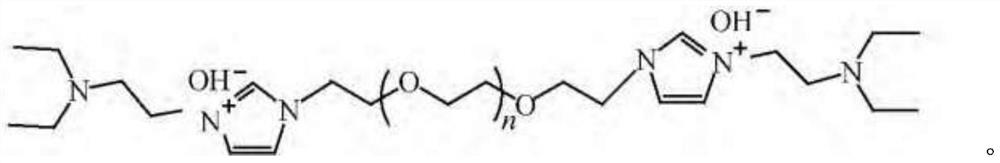

[0033] (b) adding the frozen fish skin powder obtained in step (a) into 0.25mol / L temperature-controlled alkaline ionic liquid bis-N-(2-diethylamino)ethyl polyethylene glycol bis-imidazole sodium hydroxide, First, at 20°C, the ultrasonic power density is 0.25w / cm 2 , ultrasonic treatment for 15min; then at 12°C, ultrasonic power density 1.0w / cm 2 , ultrasonic treatment for 6min; finally at 5°C, ultrasonic power density 2.2w / cm 2 , sonicated for 2 minutes; centrifuged and dried to obtain fish skin powder after removing impurities and defatting;

[0034] (2) Put the fish skin powder in 2wt% acetic acid solution, add pepsin according to the addition amount of 0.01 mg pepsin in every g fish skin powder, extract collagen under the condition of temperature 3 ℃, centrifuge and dry, and obtain...

Embodiment 2

[0050] (1) Pretreatment of Japanese yellow croaker skin:

[0051] (a) After the fish skin is cleaned, freeze-dried, pulverized to a particle size of 50 μm to obtain fish skin frozen powder;

[0052] (b) adding the frozen fish skin powder obtained in step (a) into 0.100mol / L temperature-controlled alkaline ionic liquid bis-N-(2-diethylamino)ethyl polyethylene glycol bis-imidazole potassium hydroxide, First, at 20°C, the ultrasonic power density is 0.35w / cm 2 , ultrasonic treatment for 10min; then at 15°C, ultrasonic power density 0.7w / cm 2 , ultrasonic treatment for 5min; finally at 4°C, ultrasonic power density 2.5w / cm 2 , sonicated for 1 min; centrifuged and dried to obtain fish skin powder after removing impurities and defatting;

[0053] (2) Put the fish skin powder in 5wt% acetic acid solution, add pepsin according to the addition amount of 0.03mg pepsin in every g fish skin powder, extract collagen under the condition of temperature 5 ℃, centrifuge and dry, and obtain ...

Embodiment 3

[0057] (1) Pretreatment of Japanese yellow croaker skin:

[0058] (a) After the fish skin is cleaned, freeze-dried, pulverized to a particle size of 25 μm to obtain fish skin frozen powder;

[0059] (b) adding the frozen fish skin powder obtained in step (a) into 0.50mol / L temperature-controlled alkaline ionic liquid bis-N-(2-diethylamino)ethyl polyethylene glycol bis-imidazole sodium hydroxide, First, at 25°C, the ultrasonic power density is 0.2w / cm 2 , sonicate for 10min; then at 10°C, ultrasonic power density 1.5w / cm 2 , sonicate for 8min; finally at 8°C, ultrasonic power density 2.5w / cm 2 , sonicated for 1 min; centrifuged and dried to obtain fish skin powder after removing impurities and defatting;

[0060] (2) Put the fish skin powder in 4wt% acetic acid solution, add pepsin according to the addition amount of 0.02mg pepsin in every g fish skin powder, extract collagen under the condition of temperature 4°C, centrifuge and dry to obtain Japanese Yellow croaker skin c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com