A method for preparing a biologically derived dipeptidyl peptidase-IV inhibitor

A dipeptidyl peptidase and inhibitor technology, applied in the field of protein extraction, can solve the problem of low resource utilization, and achieve the effects of low addition amount, rapid enzymatic hydrolysis and significant physiological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

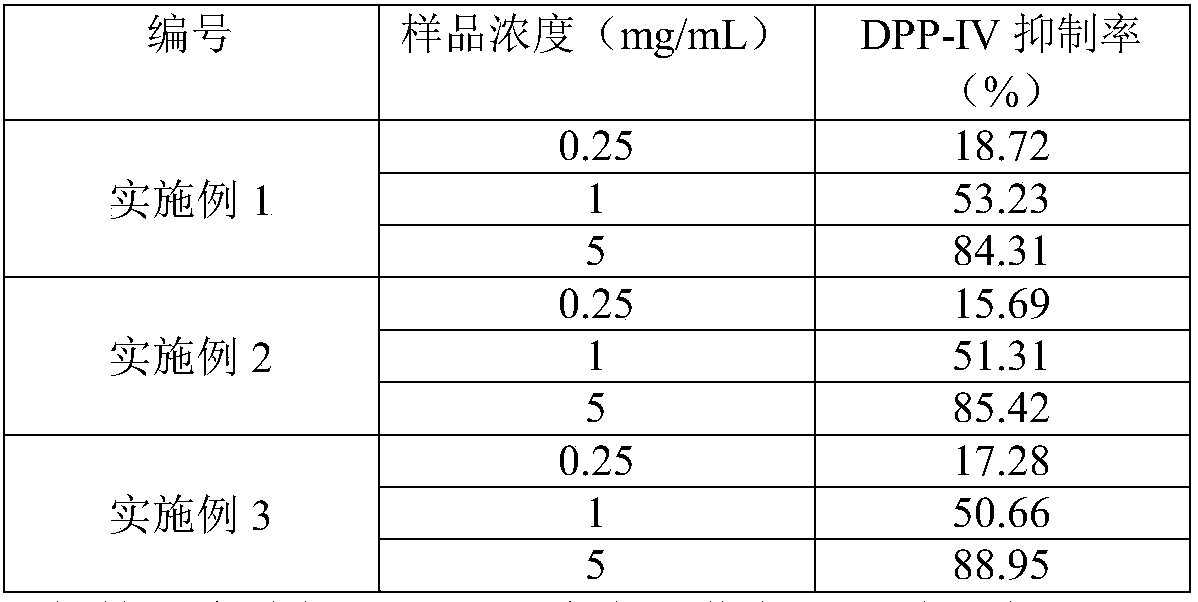

Embodiment 1

[0031] (1) Pretreating the skin of Japanese yellow croaker:

[0032] (a) After the fish skin is washed, freeze-dried, and crushed to a particle size of 25-50 μm to obtain frozen fish skin powder;

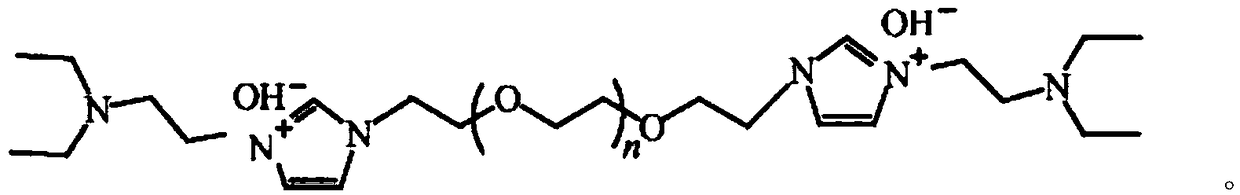

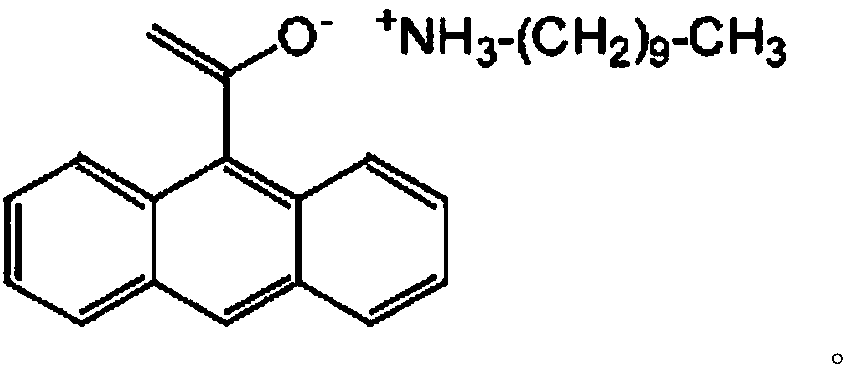

[0033] (b) Add the frozen fish skin powder obtained in step (a) to 0.25 mol / L temperature-controlled alkaline ionic liquid bis-N-(2-diethylamino) ethyl polyethylene glycol bisimidazole sodium hydroxide, First at 20℃, the ultrasonic power density is 0.25w / cm 2 , Ultrasonic treatment for 15min; then at a temperature of 12℃, ultrasonic power density 1.0w / cm 2 , Ultrasonic treatment for 6min; finally at 5℃, the ultrasonic power density is 2.2w / cm 2 , Ultrasonic treatment for 2min; centrifugation, drying, get the fish skin meal after removing impurities and degreasing;

[0034] (2) Put fish skin powder into 2wt% acetic acid solution, add pepsin according to the addition amount of 0.01mg pepsin per gram of fish skin powder, extract collagen at 3℃, centrifuge and dry, get Japan Huanggu fish skin...

Embodiment 2

[0050] (1) Pretreating the skin of Japanese yellow croaker:

[0051] (a) After the fish skin is washed, freeze-dried, and crushed to a particle size of 50 μm to obtain frozen fish skin powder;

[0052] (b) Add the frozen fish skin powder obtained in step (a) to 0.100mol / L temperature-controlled alkaline ionic liquid bis-N-(2-diethylamino)ethyl polyethylene glycol bisimidazole potassium hydroxide, First at 20℃, the ultrasonic power density is 0.35w / cm 2 , Ultrasonic treatment for 10min; then at 15℃, the ultrasonic power density is 0.7w / cm 2 , Ultrasonic treatment for 5min; finally at 4℃ temperature, ultrasonic power density 2.5w / cm 2 , Ultrasonic treatment for 1min; centrifugation, drying, get the fish skin meal after removing impurities and degreasing;

[0053] (2) Put fish skin powder into 5wt% acetic acid solution, add pepsin according to the addition amount of 0.03mg pepsin per g fish skin powder, extract collagen at a temperature of 5℃, centrifuge and dry, get Japan Huanggu fish...

Embodiment 3

[0057] (1) Pretreating the skin of Japanese yellow croaker:

[0058] (a) After the fish skin is washed, freeze-dried, and crushed to a particle size of 25 μm to obtain frozen fish skin powder;

[0059] (b) Add the frozen fish skin powder obtained in step (a) to 0.50mol / L temperature-controlled alkaline ionic liquid bis-N-(2-diethylamino)ethyl polyethylene glycol bisimidazole sodium hydroxide, First, at 25℃, the ultrasonic power density is 0.2w / cm 2 , Ultrasonic treatment for 10min; then at 10℃ temperature, ultrasonic power density 1.5w / cm 2 , Ultrasonic treatment for 8min; finally at 8℃ temperature, ultrasonic power density 2.5w / cm 2 , Ultrasonic treatment for 1min; centrifugation, drying, get the fish skin meal after removing impurities and degreasing;

[0060] (2) Put fish skin powder into 4wt% acetic acid solution, add pepsin according to the addition amount of 0.02mg pepsin per g fish skin powder, extract collagen at 4℃, centrifuge and dry, get Japan Huanggu fish skin collagen; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com