Decorative thermal insulation guard bearing integrated dense rib composite prefabricated exterior wall plate and preparation method thereof

A technology of exterior wall panels and dense ribs, applied in the direction of manufacturing tools, building components, ceramic molding machines, etc., can solve the unfavorable development of thermal insulation and structural integration of walls, the inability to realize standard industrial production, poor fire performance, and poor durability, etc. Problems, to achieve the effect of reducing thermal bridge effect, light weight, good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

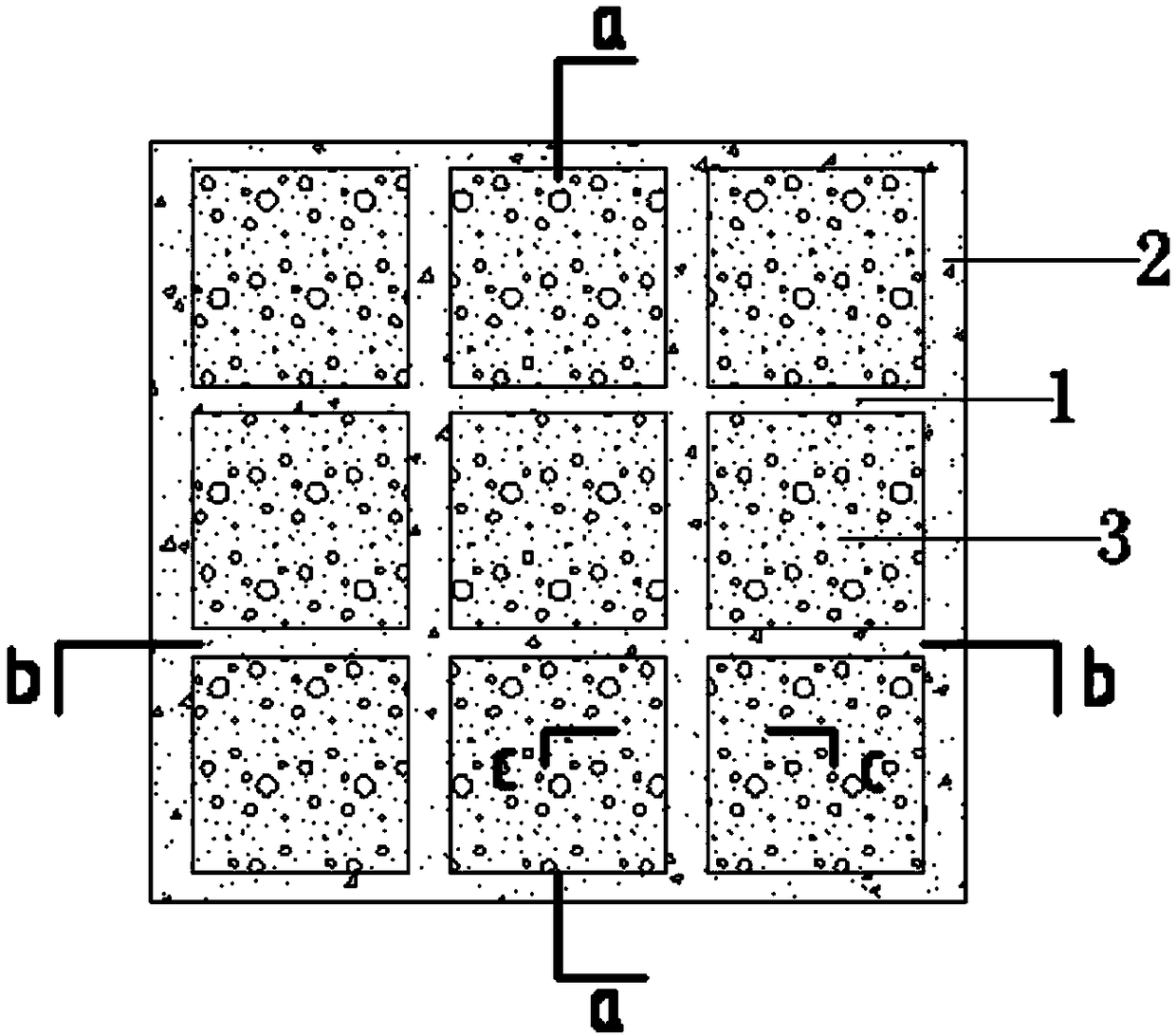

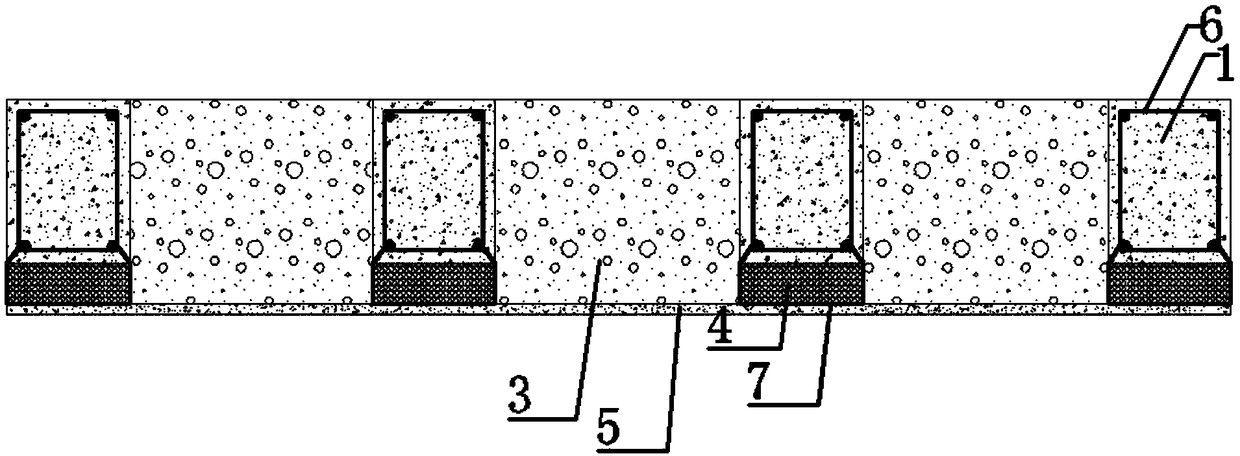

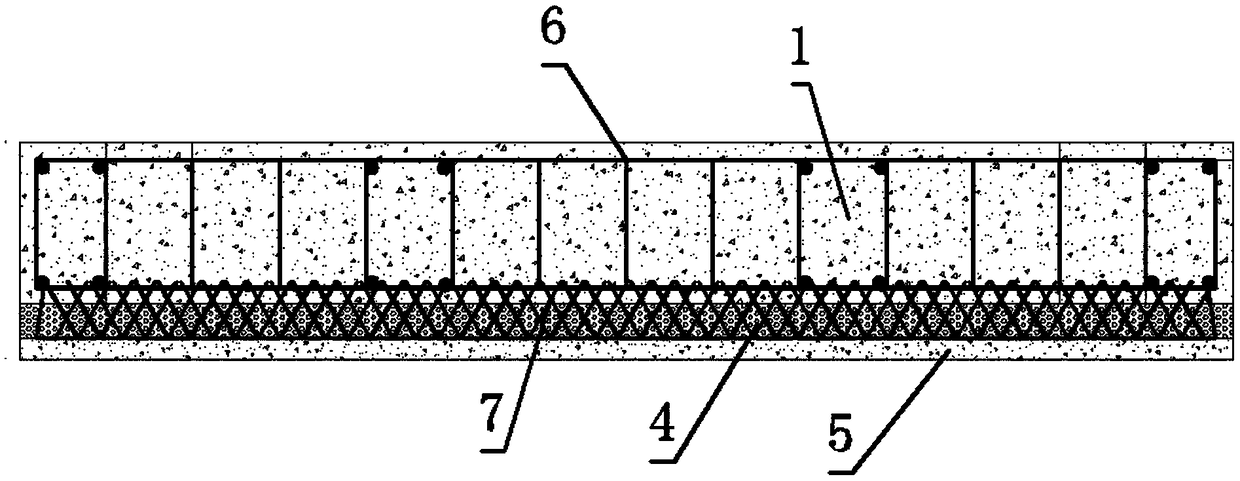

[0038] see Figure 1 ~ Figure 3 , a decorative thermal insulation enclosure load-bearing integrated dense rib composite prefabricated exterior wall panel, including surface layer 5, rib beam 1, rib column 2, thermal insulation block 3 and thermal insulation strip 4, surface layer 5 has a decorative function, in the The inner side of the surface layer 5 is bonded with a thermal insulation block layer, and the thermal insulation block layer is laid into a grid structure, and glass fiber mesh cloth arranged sequentially from bottom to top is arranged between the grids and around the thermal insulation block layer. 7. Insulation strip 4, rib beam 1 and rib column 2, the glass fiber mesh cloth 7 is bonded on the surface layer 5, the insulation str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com