Water drainage and gas production intensity determination method capable of improving water drainage and gas production efficiency of coal bed gas

A strength-determined, coal-bed methane technology, applied in the direction of mining fluid, earthwork drilling, measurement, etc., can solve the problems of difficult drainage plan design, non-uniform distribution, low efficiency of drainage and gas recovery, etc., and reduce drainage errors efficiency and production management costs, strong pertinence and universal applicability, and the effect of improving single well gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

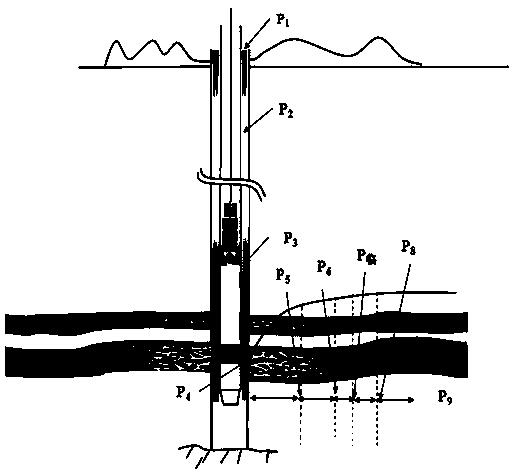

[0021] Combine below figure 1 The present invention will be described in detail.

[0022] A method for determining the extraction intensity that can improve the extraction efficiency of coalbed methane, the determination of the extraction intensity is divided into the following stages:

[0023] (1) In the unidirectional flow stage, the casing pressure in the well is zero at this time, and the formation is single-phase water flow. Since the reservoir energy is sufficient in the single-phase flow stage, the stress sensitivity damage is small, and appropriately increasing the drainage intensity can achieve the dredging of seepage channels, The effect of increasing the flowback rate can effectively expand the pressure drop range and provide a material basis for high and stable production in the later stage. Therefore, after the test pumping is over, gradually increase the working system and gradually increase the drainage intensity according to the increase rate △P=10Kpa / d;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com