Carbon fiber compound core wire production line intelligent video monitoring method and system

An intelligent video monitoring and production line technology, applied in closed-circuit television systems, image data processing, instruments, etc., can solve problems such as inability to guarantee product quality, large investment in manpower and material resources, etc., achieve transparency in the production process, improve quality, and save manpower and material resources input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

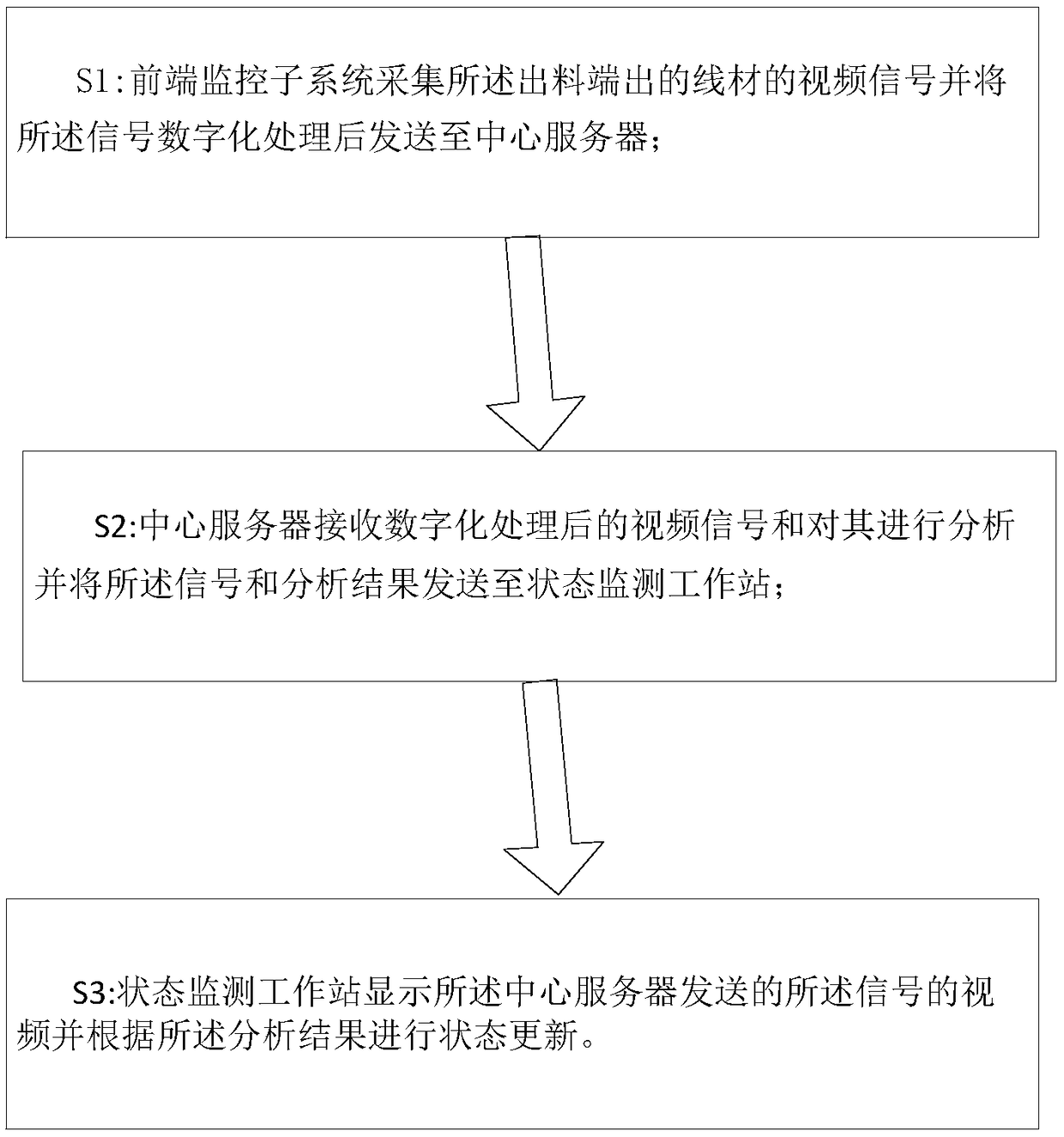

[0050] Such as figure 1 As shown, the present invention provides a method for intelligent video monitoring of a carbon fiber composite core wire production line, the method comprising:

[0051] S1: The front-end monitoring subsystem collects the video signal of the wire coming out of the discharge end and digitally processes the signal and sends it to the central server;

[0052] S2: The central server receives the digitally processed video signal and analyzes it, and sends the signal and the analysis result to the state monitoring workstation;

[0053] S3: The status monitoring workstation displays the video of the signal sent by the central server and updates the status according to the analysis result.

[0054] The analysis includes:

[0055] The central server sequentially performs grayscale conversion, histogram equalization, median filtering, contrast enhancement, binarization processing and binary image filtering on the image of the video signal to obtain a binary ima...

Embodiment 2

[0067] Based on the same inventive concept, the present invention provides an intelligent video monitoring system for a carbon fiber composite core wire production line, the system comprising:

[0068] The front-end monitoring subsystem installed at the discharge end of the production line is used to collect the video signal of the wire rod from the discharge end and send the signal to the central server after digital processing;

[0069] The central server is used to receive the digitally processed video signal and analyze it and send the signal and analysis results to the state monitoring workstation;

[0070] The state monitoring workstation is used to display the video of the signal sent by the central server and update the state according to the analysis result.

[0071] The front end of the discharge end of the production line includes:

[0072] Between the export pulley and the output wheel of the carbon fiber composite mandrel production line; or,

[0073] Between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com