Production method of pure natural ceromel

A production method and honeycomb technology, which are applied in the field of bee product production, can solve the problems of low resistance of bee colonies, easy loss, and lower temperature of nest boxes, so as to maintain colony potential or increase colony potential, improve production capacity, and achieve production efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

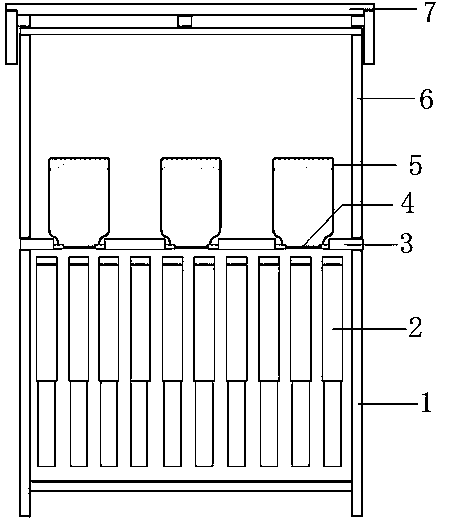

[0035] 1. Processing and making beehives; figure 1 As shown, the beehive includes a nest box 1 and a successor box 6. Several nest frames 2 are arranged in the nest box 1, and a plane king partition 3 is placed above the nest box 1, and the successor box 6 is placed on the king partition 3. 6. Case cover 7 is set above.

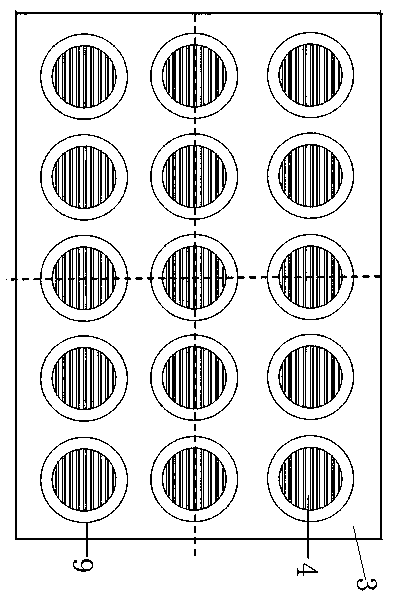

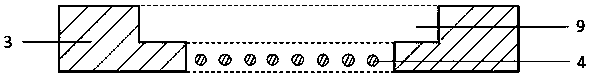

[0036] figure 2 Shown, described king partition plate 3 is that a length is 510mm, and width is 410mm, and thickness is the flat plate of 15mm, and flat plate is provided with some stepped holes 9, and in the small hole of stepped hole 9, separated king grid 4 is set, and the size of stepped hole 9 A glass honeycomb bottle 5 is arranged in the hole, and the king grid 4 is covered in the mouth of the honeycomb bottle 5, and a natural nest foundation 8 is arranged in the honeycomb bottle 5 and at the bottom of the bottle; the natural nest foundation 8 is cut into a length of 40mm by using a honeycomb , a strip fragment with a width of 10 mm.

[0037] imag...

Embodiment 2

[0042] Embodiment 2: In this embodiment, the diameter of the large hole is 70 mm, the diameter of the small hole is 50 mm, the diameter of the bottle mouth is 60 mm, and the depth is 70-140 mm. Others are the same as in Example 1.

Embodiment 3

[0043]Embodiment 3: In this embodiment, the diameter of the large hole is 70 mm, the diameter of the small hole is 40 mm, the diameter of the mouth of the bottle is 50 mm, and the depth is 70-140 mm. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com