Soil washing liquid, application method and equipment

A soil leaching and equipment technology, applied in the field of soil leaching liquid, can solve the problems of small application range and unusable soil for farming, etc., and achieve the effect of improving fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of soil washing solution provided by the invention comprises: solute and solvent, wherein solute comprises p-methoxyphenol, potassium persulfate, oxalic acid, aluminum triacetylacetonate, magnesium sulfate heptahydrate, solvent is water, according to mass percentage, Its p-methoxyphenol is 5.4-5.8%, potassium persulfate is 2.2-2.8%, and oxalic acid is 1-2%. The solute also includes ethylenediaminetrisuccinic acid, wherein the mass percentage of ethylenediaminetrisuccinic acid is 0.8-1.2%. Wherein the mass percent of magnesium sulfate heptahydrate is 5-6%. Wherein the mass percentage of aluminum triacetylacetonate is 1-2%.

Embodiment 2

[0035] The invention also discloses a method for using the soil washing liquid, comprising the following steps:

[0036] 1) Pulverize the contaminated soil;

[0037] 2) Sieve the crushed contaminated soil to obtain fine-grained soil with a particle size less than 3cm;

[0038] 3) Put the fine-grained soil into the soil eluent treatment equipment, add water equal to 1 / 2 to 1 / 3 of the weight of the soil, and stir to push the soil to turn;

[0039] 4) Add soil eluent, stir and turn over to mix, and the amount of eluent added is 1 to 2 times the weight of the soil. ;

[0040]5) Separate and take out the soil after fine treatment and the soil after coarse treatment.

Embodiment 3

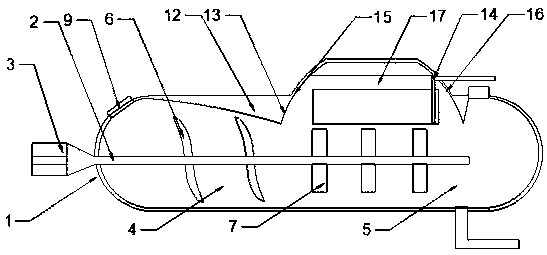

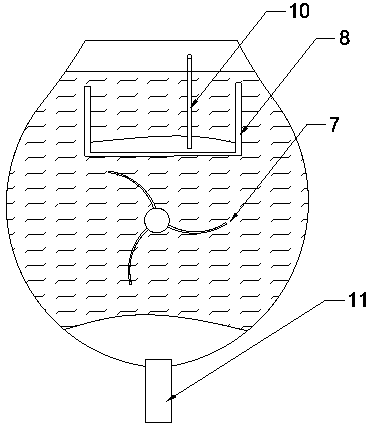

[0042] Such as figure 1 , figure 2 , image 3 As shown, the present invention also discloses a soil washing liquid treatment equipment applied in the method of using the soil washing liquid, which includes a horizontal tank 1 and a horizontally arranged rotating shaft 2, and the rotating shaft is externally connected to a drive motor 3 ; The horizontal tank body has a primary treatment area 4 close to the drive motor side and a secondary separation area 5 on the other side; the rotating shaft is equipped with a propeller-shaped horizontal drive blade 6 for driving the soil by a The primary treatment area turns over and enters the secondary separation area; the horizontal driving blade is positioned on the rotating shaft on one side of the primary processing area; Turn the soil at the bottom into the upper layer to mix with the soil eluent. The turning blade is an arc-shaped blade extending radially from the rotating shaft; the upper part of the secondary separation area has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com