Mobile Foam Abrasive Jet Fire Cutting Machine

A technology of abrasive jet and cutting machine, applied in the direction of abrasive jet machine tools, abrasives, abrasive feeding devices, etc., can solve the problems of polluting the environment, leaving hidden dangers, time-consuming and labor-intensive problems, and achieves small size, convenient operation and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

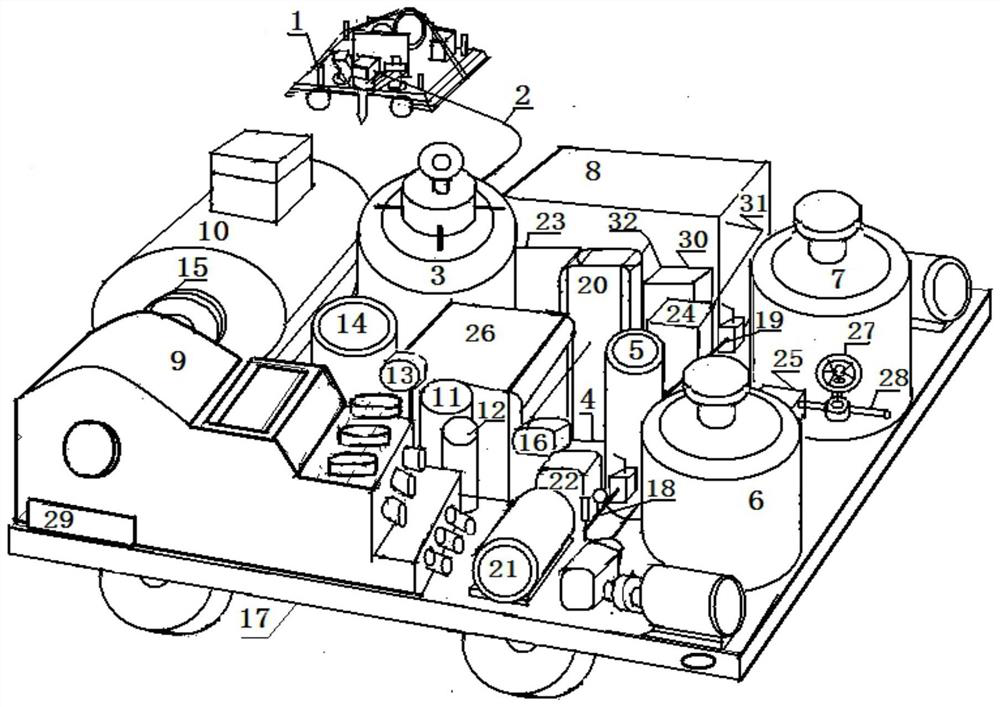

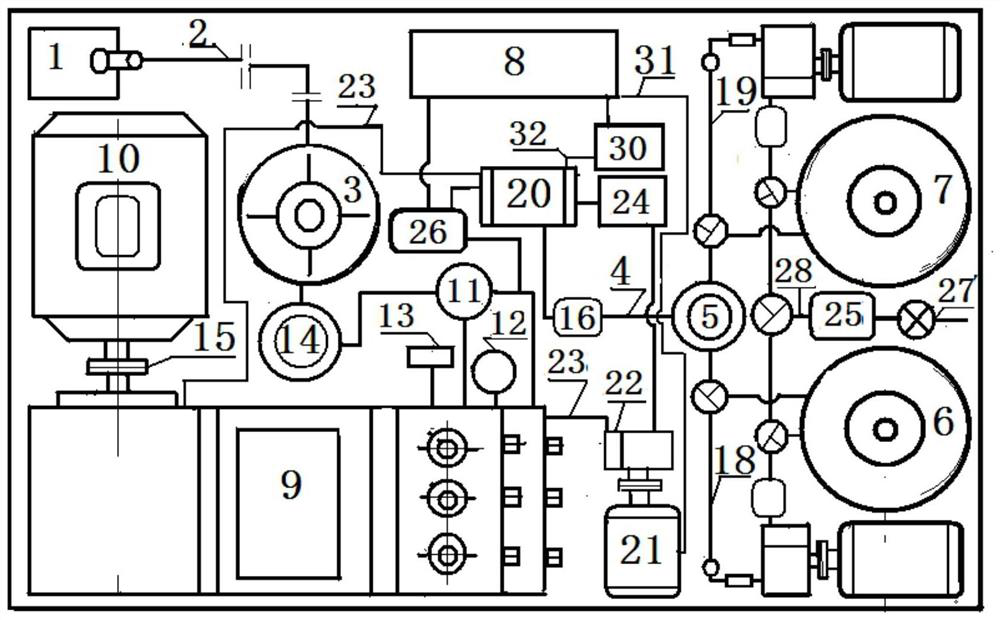

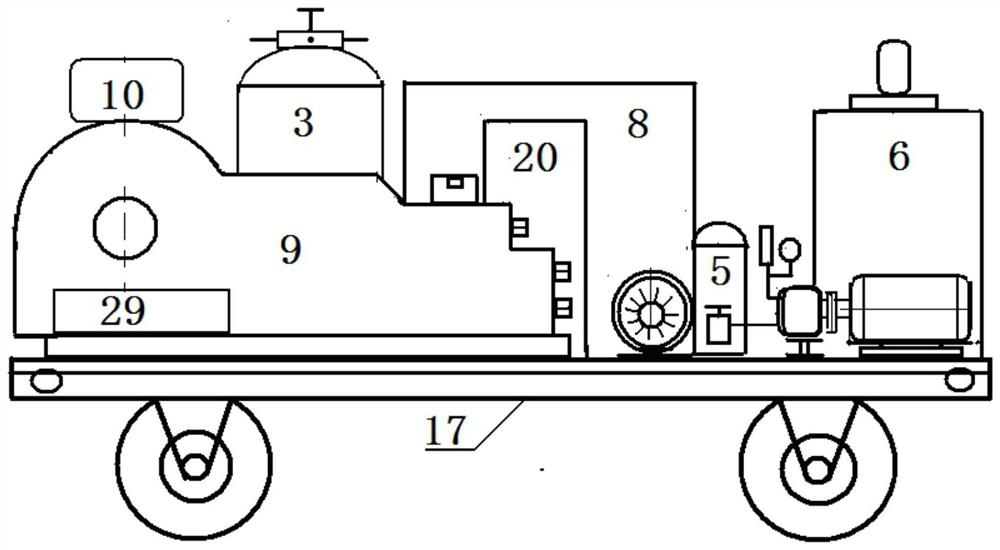

[0038] Figure 1( Figure 1A , Figure 1B , Figure 1C ), (1) fire-fighting cutting head assembly described in the embodiments of the present invention, (2) high-pressure pipe, (3) abrasive mixing tank assembly, (4) foam liquid supply pipeline, (5) foam liquid Mixing valve, (6) A liquid supply assembly, (7) B liquid supply assembly, (8) Cutting machine power distribution cabinet, (9) Booster pump, (10) Explosion-proof motor, (11) Foam liquid unloading Relief Valve, (12) Foam Relief Valve, (13) Pressure Gauge, (14) Foam Accumulator, (15) Coupling, (16) Foam Filter, (17) Foam Assembly Base Frame, (18) A liquid pipeline, (19) B liquid pipeline, (20) heat exchanger, (21) circulating pump frequency modulation motor, (22) circulating pump, (23) circulating pipeline, (24) hot oil filter device, (25) inlet filter, (26) pressure compensator, (27) inlet main gate valve, (28) inlet pipeline, (29) booster pump oil tank, (30) thermal controller, (31 ) Waterproof electric wire, (32) therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com