Sensorless elastic collision device and method based on industrial robot

An industrial robot, elastic collision technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as collision alarm, overload alarm, etc., to avoid damage, avoid overload alarm, and achieve good real-time effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below with reference to specific embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

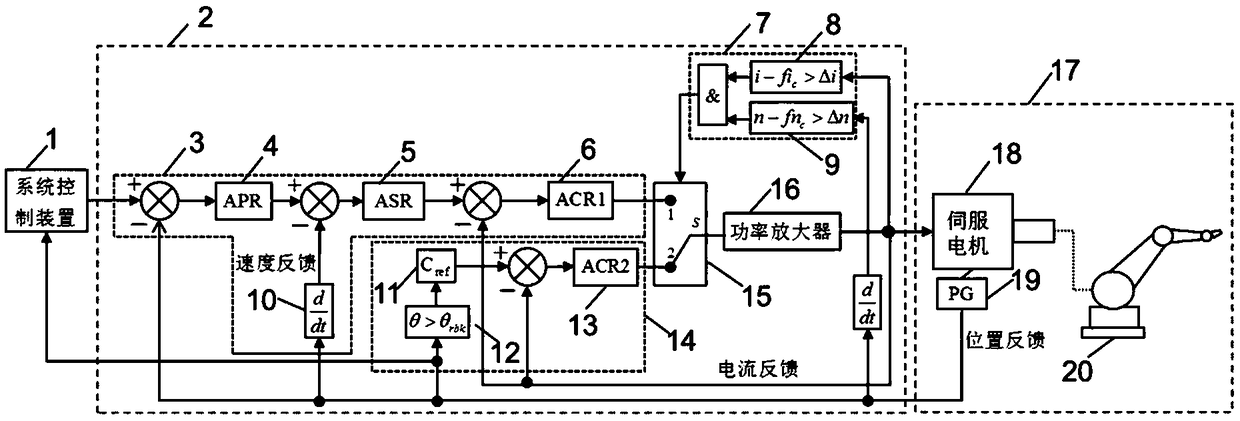

[0033] See e.g. figure 2 , The present invention provides a sensorless elastic collision device based on an industrial robot, which includes a system control device 1 , a motor servo drive device 2 and an industrial robot body 17 . The system control device 1 sends a joint position command to the motor servo drive device 2, and the motor servo drive device 2 outputs a power signal to drive the industrial robot body 17 to move.

[0034] See e.g. figure 2The motor servo drive device 2 is composed of a position speed current three-loop control device 3 , a composite control device 14 , a collision detection device 7 , a control device switch 15 and a power amplifier 16 .

[0035] The position speed current three-loop control device 3 receives the position command signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com