Manufacturing process of high-strength polytetrafluoroethylene film

A polytetrafluoroethylene and manufacturing process technology, applied in the field of manufacturing process of high-strength polytetrafluoroethylene film, can solve the problem that the strength of polytetrafluoroethylene film is relatively high, and the strength of polytetrafluoroethylene film cannot meet the application requirements, etc. problem, to achieve the effect of excellent dielectric properties and high voltage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

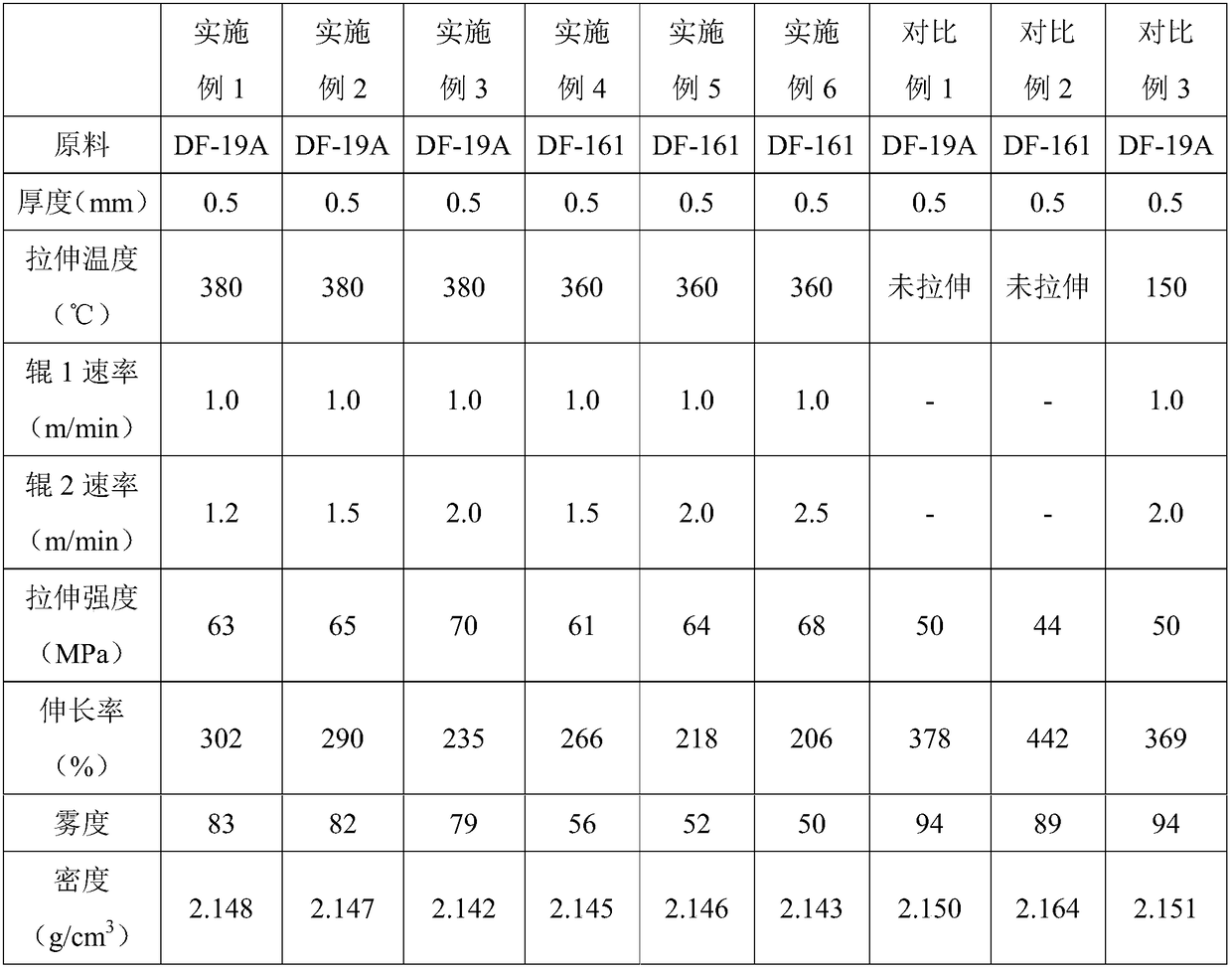

Embodiment 1

[0028] (1) Raw material sieving: sieve polytetrafluoroethylene suspension resin DF-19A through a 10-purpose sieve for subsequent use;

[0029] (2) Molding: Raise the sieved polytetrafluoroethylene suspension resin DF-19A to 25MPa at a rate of 15mm / min, hold the pressure for 15min, and take it out for use;

[0030] (3) Sintering: put the molded product obtained in step (2) into a sintering furnace, raise it from room temperature to 290°C at a rate of 3°C / min, keep it at 290°C for 10 minutes, and increase it from 290°C at a rate of 1°C / min Raise to 380°C, hold at 380°C for 8 hours, then cool down from 380°C to 290°C at a rate of 1°C / min, and cool down naturally from 290°C to room temperature, then take it out for use;

[0031] (4) turning: the sintered product obtained in (3) is turned on a lathe, and the turning film thickness is 0.5mm;

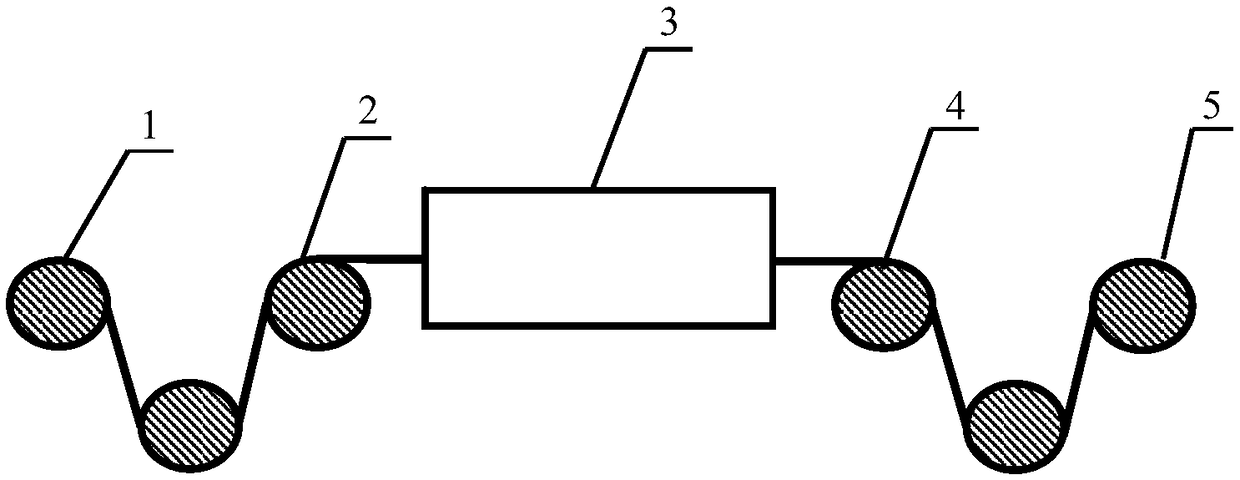

[0032] (5) Melt stretching: the turning film obtained in (4) is stretched in a stretching device, the stretching temperature is 380°C, the s...

Embodiment 2

[0034] (1) Raw material sieving: sieve polytetrafluoroethylene suspension resin DF-19A through a 10-purpose sieve for subsequent use;

[0035] (2) Molding: Raise the sieved polytetrafluoroethylene suspension resin DF-19A to 30MPa at a rate of 20mm / min, hold the pressure for 10min, and take it out for later use;

[0036] (3) Sintering: put the molded product obtained in step (2) into a sintering furnace, raise it from room temperature to 290°C at a rate of 3°C / min, keep it at 290°C for 10 minutes, and increase it from 290°C at a rate of 1°C / min Raise to 380°C, hold at 380°C for 8 hours, then cool down from 380°C to 290°C at a rate of 1°C / min, and cool down naturally from 290°C to room temperature, then take it out for use;

[0037] (4) turning: the sintered product obtained in (3) is turned on a lathe, and the turning film thickness is 0.5mm;

[0038] (5) Melt stretching: the turning film obtained in (4) is stretched in a stretching device, the stretching temperature is 380°C,...

Embodiment 3

[0040] (1) Raw material sieving: sieve polytetrafluoroethylene suspension resin DF-19A through a 10-purpose sieve for subsequent use;

[0041] (2) Molding: Raise the sieved polytetrafluoroethylene suspension resin DF-19A to 20MPa at a rate of 15mm / min, hold the pressure for 15min, and take it out for later use;

[0042] (3) Sintering: put the molded product obtained in step (2) into a sintering furnace, raise it from room temperature to 290°C at a rate of 3°C / min, keep it at 290°C for 10 minutes, and increase it from 290°C at a rate of 1°C / min Raise to 380°C, hold at 380°C for 8 hours, then cool down from 380°C to 290°C at a rate of 1°C / min, and cool down naturally from 290°C to room temperature, then take it out for use;

[0043] (4) turning: the sintered product obtained in (3) is turned on a lathe, and the turning film thickness is 0.5mm;

[0044] (5) Melt stretching: the turning film obtained in (4) is stretched in a stretching device, the stretching temperature is 380°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com