Process for microelectrolysis catalytic oxidation and biochemical treatment of high-concentration waste water

A high-concentration wastewater, catalytic oxidation technology, applied in aerobic and anaerobic process treatment, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of wastewater COD difficult to degrade, membrane fouling, etc., and achieve fast , Anti-poisonous substances and strong system impact ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is a further description of the present invention to better understand the present invention:

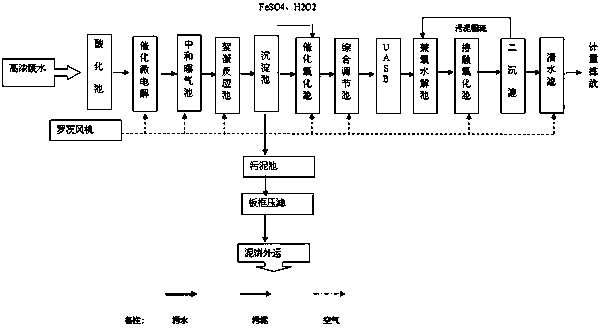

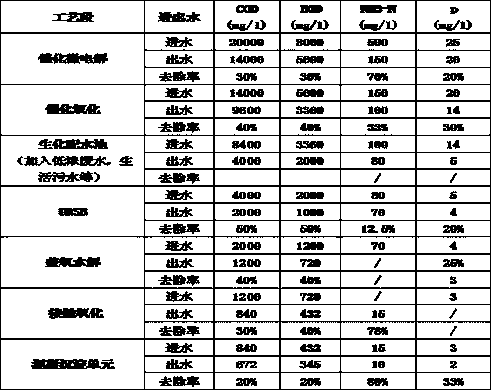

[0031] 1. According to the high-concentration wastewater quality index, it is characterized by high COD, low B / C ratio, and high toxicity. If the biochemical process is directly used for this type of wastewater, the entire biochemical process will be paralyzed. Taking necessary physical and chemical pretreatment measures is the prerequisite for the treatment of this type of wastewater. In response to the above problems, our company's physicochemical pretreatment technology will adopt the domestic leading catalytic microelectrolysis and three-phase catalytic oxidation pretreatment technology, and the biochemical anaerobic section will adopt the A2O process. The combination of physicochemical and biochemical methods can increase the impact load of the entire wastewater treatment system on high-concentration organic wastewater treatment.

[0032] 2. Characteristics of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com