Impurity of polymyxin B sulfate and preparation method thereof

A technology of polymyxin and sulfuric acid, which is applied to the field of impurities of polymyxin B sulfate and separation and preparation thereof, can solve the problems of increasing the content of degraded impurities, and achieve the effects of improving quality and ensuring safety and effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

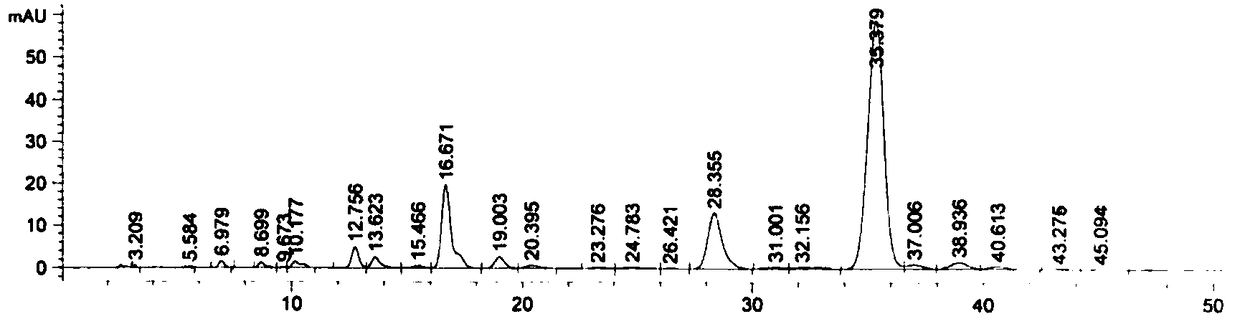

[0031] Example 1 Separation and Purification of Polymyxin B Sulfate Impurity D17

[0032] 1. Crude production of impurity D17

[0033] Polymyxin B sulfate was dissolved in 5% acetonitrile solution, prepared by Agilent SD-1 preparative liquid phase; chromatographic column C18 (5um, 20×250mm); mobile phase was acetonitrile: sodium sulfate solution 4.46g / L=20 : 80; detection wavelength 215nm; flow rate 25mL / min. Fractions were collected and enriched by C18 preparative chromatographic column. It was eluted with 80% acetonitrile, and the impurity crude extract solution was collected.

[0034] 2. Refining of impurity D17

[0035] The collected impurity crude extract solution was concentrated under reduced pressure at 35°C to remove acetonitrile. Put the concentrated solution on the preparative column for purification again, collect the fractions in which the content of impurity D17 is greater than 90%, enrich and desalt them, and obtain a concentrated solution of polymyxin B sul...

Embodiment 2

[0038] Example 2 Structural Identification of Polymyxin B Sulfate Impurity D17

[0039] Gained impurity D17 in embodiment 1 is detected through high-resolution mass spectrometry, and the results are as follows:

[0040] High resolution mass spectrum m / z of polymyxin B sulfate impurity: 1203.7587[M+H]+, 1225.7408[M+Na]+.

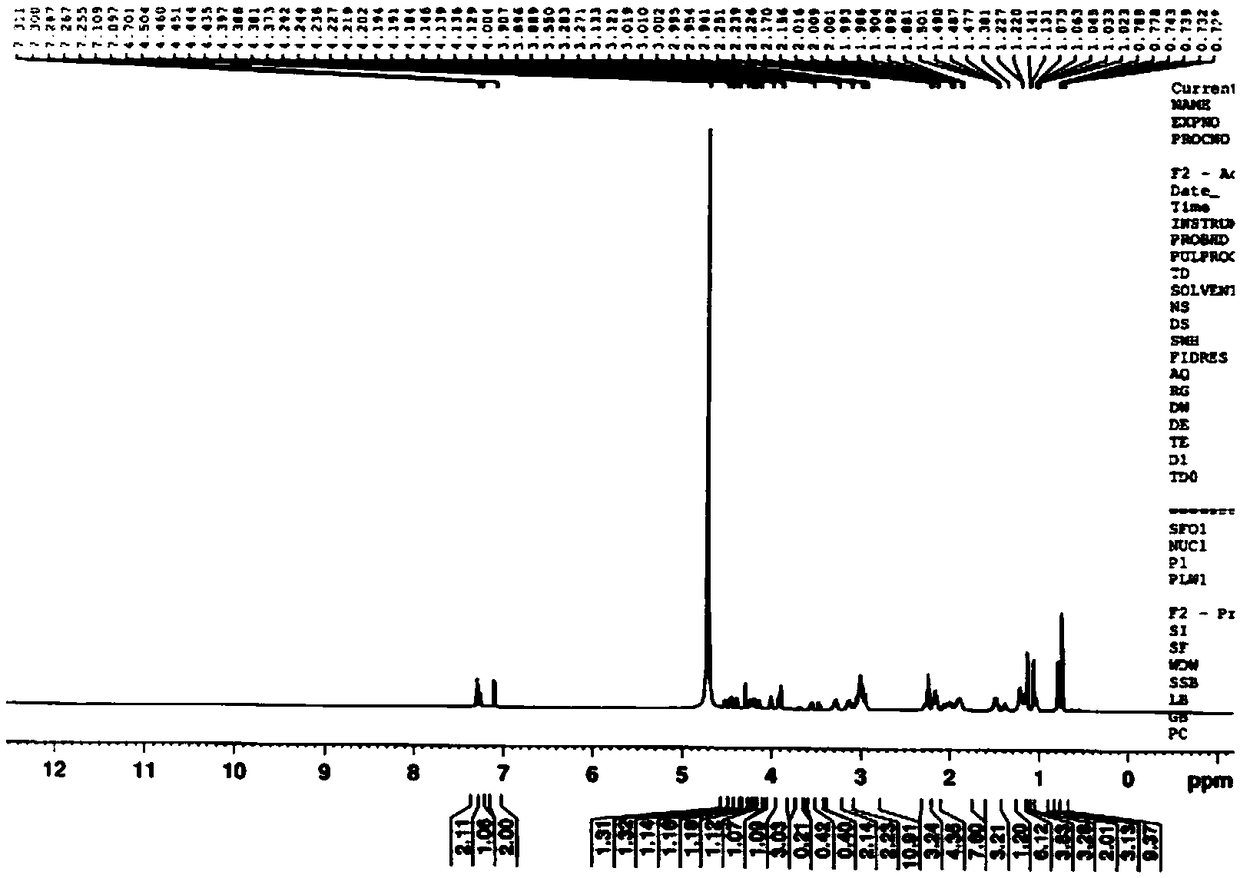

[0041] The obtained impurity D17 in embodiment 1 is carried out nuclear magnetic detection again, obtain proton nuclear magnetic resonance spectrum and carbon nuclear magnetic resonance spectrum, the result is as follows:

[0042] 1 H NMR (600MHz, D2O) δ7.30(t, J=7.2Hz, 2H), 7.25(t, J=7.2Hz, 1H), 7.10(d, J=7.2Hz, 2H), 4.72(t, J =7.2Hz, 1H), 4.50(dd, J=9.0, 4.2Hz, 1H), 4.45(dd, J=9.6, 4.2Hz, 1H), 4.38(dd, J=9.0, 4.2Hz, 1H), 4.29 (d, J=4.2Hz, 1H), 4.23(dd, J=9.6, 3.0Hz, 1H), 4.20(dd, J=6.6, 4.2Hz, 1H), 4.14(dd, J=6.6, 4.2Hz, 1H), 4.00(t, J=7.8Hz, 1H), 3.91(dd, J=10.2, 4.2Hz, 1H), 3.90(m, 1H), 3.89(d, J=4.8Hz, 1H), 3.29( m, 2H), 3.13(m, 2H), 3.06(m, 1H), 3....

Embodiment 3

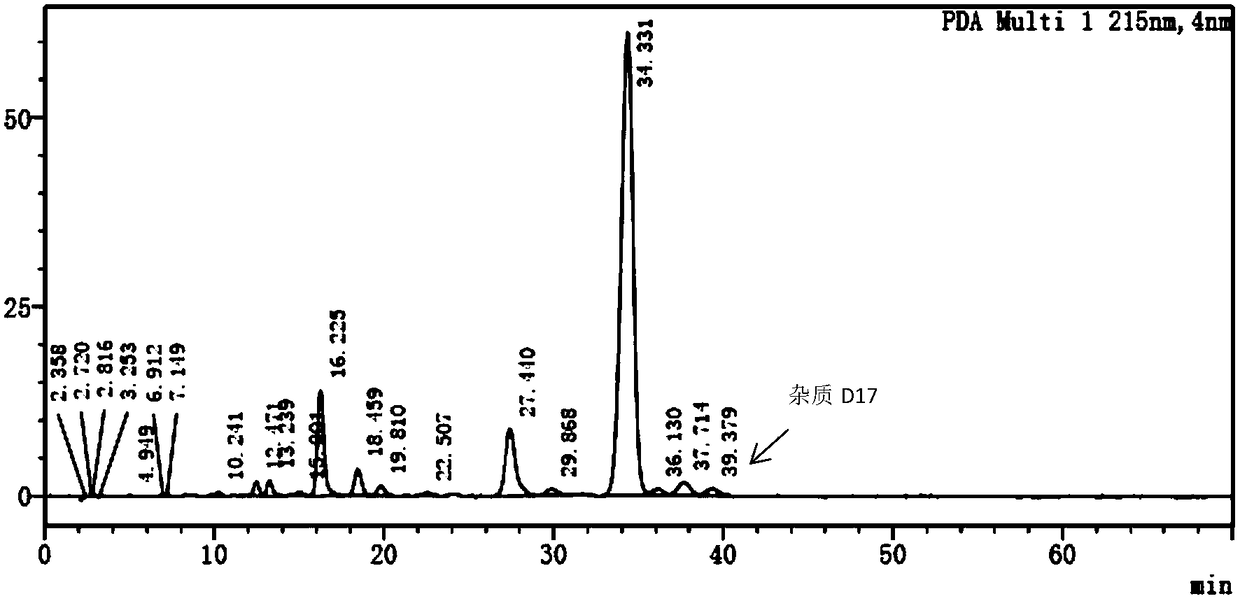

[0046] The investigation of the factor of impurity D17 produced by the degradation of polymyxin B sulfate of embodiment 3

[0047] 1. The influence of solution pH

[0048] Weigh 2.0g of the sample, dissolve it in 200ml of pure water, stir to dissolve it, and pack in 5ml per bottle. Take 4 bottles of samples without pH adjustment (pH 6.5) and samples with pH adjustment of 8.5, 8.8, 9.3, 9.8, and 10.3, respectively. Four samples at the same pH were degraded at 33°C for 20min, 1h, 2h, and 4h, respectively, and samples were taken for HPLC detection.

[0049] The chromatographic conditions are: Agilent 1260 high performance liquid chromatography;

[0050] Chromatographic column: Waters symmetry-C18 4.6mm×25cm;

[0051] Mobile phase: acetonitrile: sodium sulfate solution (4.46g / L)=20:80;

[0052] Flow rate: 1mL / min;

[0053] Column temperature: 30°C;

[0054] Detection wavelength: 215nm.

[0055] The content of impurity D17 was counted to obtain the content of D17 after degra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com