Preparation method of blue acid dye finished product

A technology of acid dyes and finished products, applied in the direction of organic dyes, etc., can solve the problems of dye dust pollution, achieve the effects of reducing dust pollution, environmental protection and cleaning process, reducing energy consumption and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

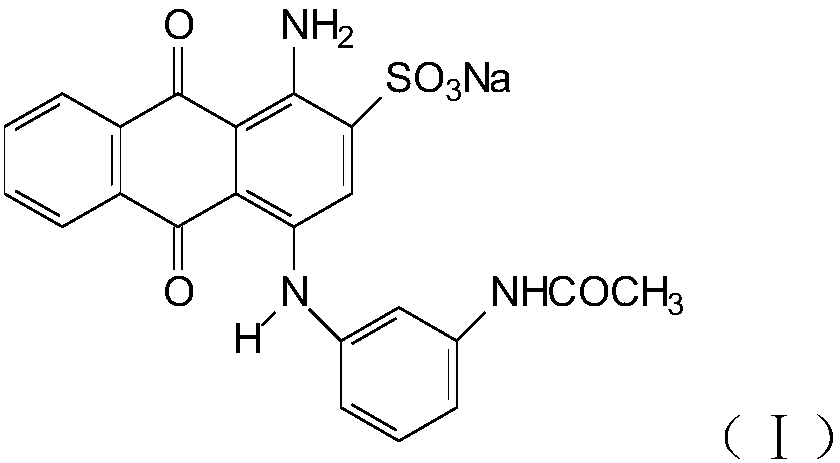

[0036] A kind of preparation method of blue acid dye finished product of the present invention, the chemical structural formula of blue acid dye is as follows:

[0037]

Embodiment 1

[0040] Add 0.8kg of copper sulfate to 10kg of water and stir until completely dissolved, then add 10kg of liquid caustic soda and 0.4kg of glucose to react, filter with suction, and dry to obtain catalyst C-1.

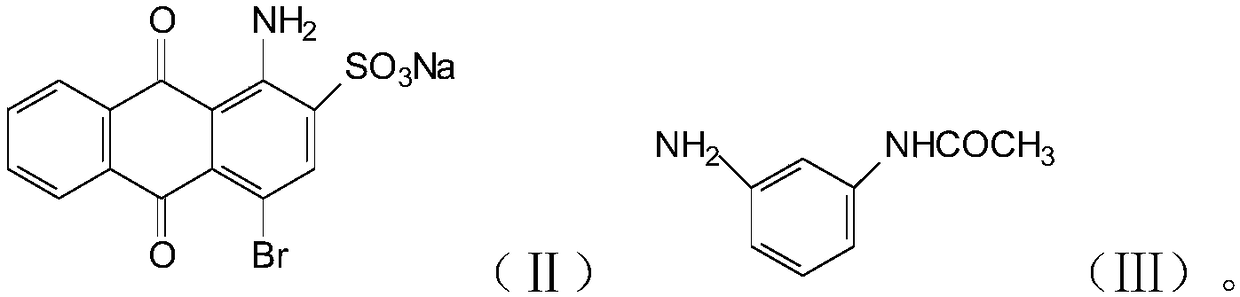

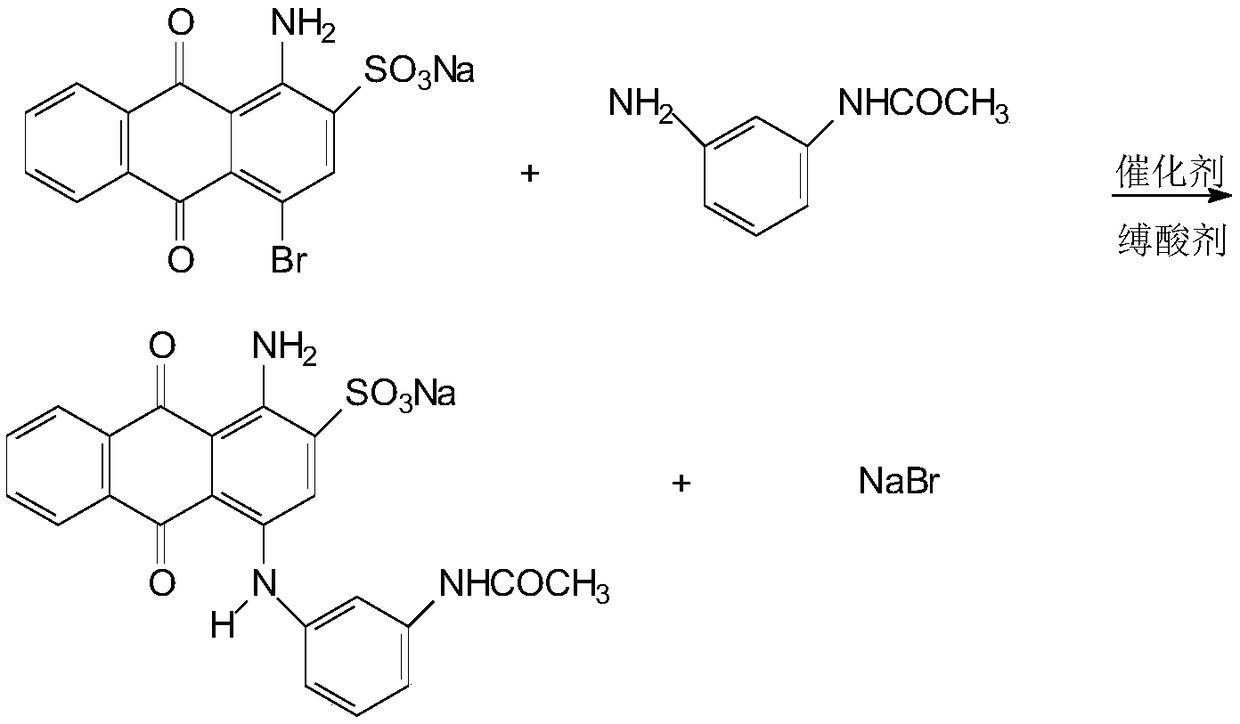

[0041] Add 2800kg of water into the reaction kettle, stir and add 382kg of compound of formula (II) (100%), stir for 10min, add 185kg of compound of formula (III) (100%), stir and heat up to 58-82°C, add catalyst C-1 , the amount of catalyst C-1 is added according to the ratio of the molar ratio of the compound of formula (II) to copper ions: 1:0.075, and soda ash is added to adjust the pH=7.5 to 9.0, and 6kg of sucrose is added during the adjustment of the pH, and then at 65 to Stir and react at 85°C for 2 to 3 hours to obtain a reaction solution;

[0042] Add 5kg of liquid caustic soda to the reaction solution, heat up to 90°C for 30 minutes, add 1000kg of water, add perlite filter aid, and filter to obtain the reaction filtrate;

[0043] Cool the reaction filtrate ...

Embodiment 2

[0046] The amount of catalyst C-1 in this example is added according to the molar ratio of the compound of formula (II) to copper ions at a ratio of 1:0.051, and other process steps and conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com