A kind of preparation method and application of aluminum alloy profiles

A technology for aluminum alloy profiles and aluminum alloys, applied in the field of aluminum alloy processing, can solve problems such as overall strength, service life and storage limitations, and achieve the effects of easy large-scale industrial production, simple production process, and improved competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

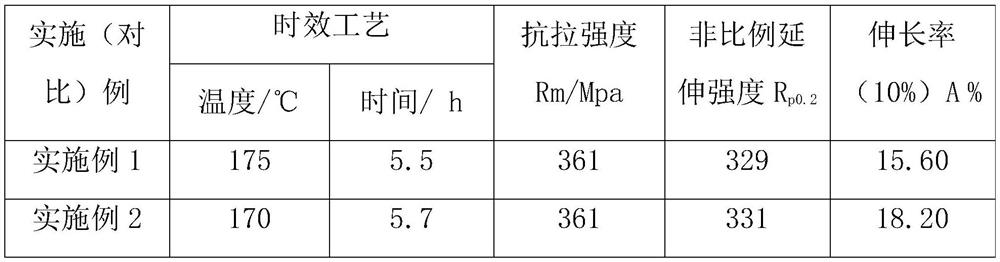

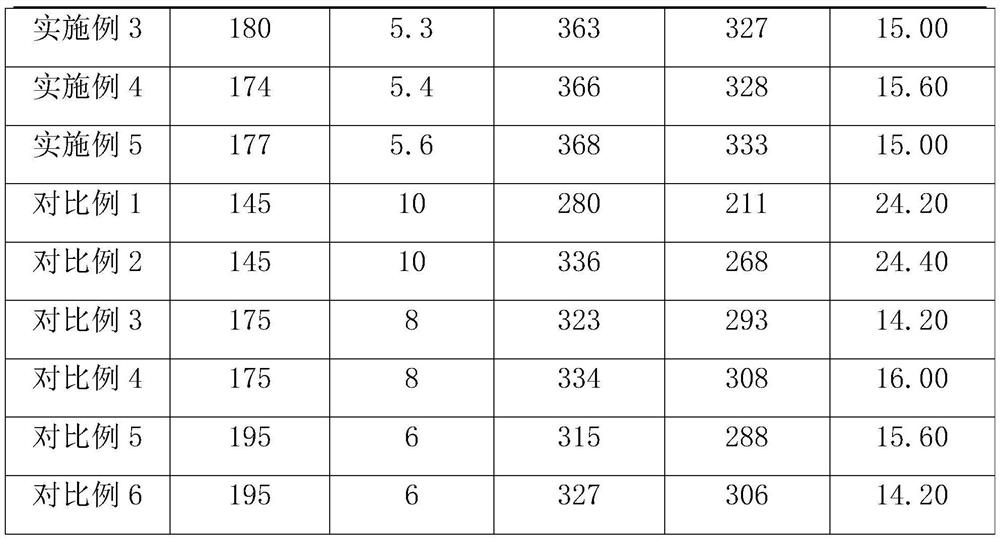

Examples

Embodiment 1

[0047] A method for preparing an aluminum alloy profile, comprising the steps of:

[0048] (1) Prepare an aluminum alloy ingot, and the composition and mass percentage thereof contained in the aluminum alloy ingot are:

[0049] Si: 1.00%, Fe: 0.25%, Cu: 0.15%, Mn: 0.50%, Mg: 0.80%, Cr: 0.12%, Ni: 0.01%, Zn: 0.01%, Ti: 0.01%, the balance is Al and impurities;

[0050] (2) heating the aluminum alloy ingot in step (1) with a multi-rod hot shear furnace at a temperature of 480°C, heating the mold to 460°C, and heating the ingot holder to 420°C;

[0051] (3) Add the aluminum alloy ingot heated in step (2) into the heated ingot barrel for extrusion treatment, wherein the extrusion ratio λ is 30, the extrusion speed is 4m / min, and the outlet temperature is 530 ℃;

[0052] (4) On-line quenching treatment of the extruded aluminum alloy, controlling the product temperature after quenching to ≤50°C;

[0053] (5) Stretching and cutting to length the aluminum alloy product after the qu...

Embodiment 2

[0057] A method for preparing an aluminum alloy profile, comprising the steps of:

[0058] (1) Prepare an aluminum alloy ingot, and the composition and mass percentage thereof contained in the aluminum alloy ingot are:

[0059] Si: 1.20%, Fe: 0.15%, Cu: 0.12%, Mn: 0.55%, Mg: 0.95%, Cr: 0.08%, Ni: 0.005%, Zn: 0.006%, Ti: 0.006%, and the balance is Al and impurities;

[0060] (2) heating the aluminum alloy ingot in step (1) with a multi-rod hot shear furnace at a temperature of 500°C, heating the mold to 480°C, and heating the ingot holder to 460°C;

[0061] (3) Add the aluminum alloy ingot heated in step (2) into the heated ingot barrel for extrusion treatment, wherein the extrusion ratio λ is 60, the extrusion speed is 10m / min, and the outlet temperature is 550 ℃;

[0062] (4) Perform on-line quenching treatment on the extruded aluminum alloy, and control the product temperature after quenching to ≤50°C;

[0063] (5) Stretch and cut to length the aluminum alloy after the q...

Embodiment 3

[0066] A method for preparing an aluminum alloy profile, comprising the steps of:

[0067] (1) Prepare an aluminum alloy ingot, and the composition and mass percentage thereof contained in the aluminum alloy ingot are:

[0068] Si: 1.10%, Fe: 0.22%, Cu: 0.13%, Mn: 0.52%, Mg: 0.85%, Cr: 0.05%, Ni: 0.008%, Zn: 0.005%, Ti: 0.008%, and the balance is Al and impurities;

[0069] (2) heating the aluminum alloy ingot in step (1) at a temperature of 485°C using a multi-rod hot shear furnace, heating the mold to 465°C, and heating the ingot holder to 430°C;

[0070] (3) Add the aluminum alloy ingot heated in step (2) into the heated ingot barrel for extrusion treatment, wherein the extrusion ratio λ is 33.96, the extrusion speed is 3m / min, and the outlet temperature is 535 ℃;

[0071] (4) Perform on-line quenching treatment on the extruded aluminum alloy, and control the product temperature after quenching to ≤50°C;

[0072] (5) Stretch and cut to length the aluminum alloy after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com