Method for preparing three-layer composite wave-absorbing material according to one-step method

A technology of wave absorbing material and layer compounding, applied in the manufacture of rayon, single-component synthetic polymer rayon, chemical characteristics of fibers, etc., can solve the problems of high density, single absorption frequency band, weak absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

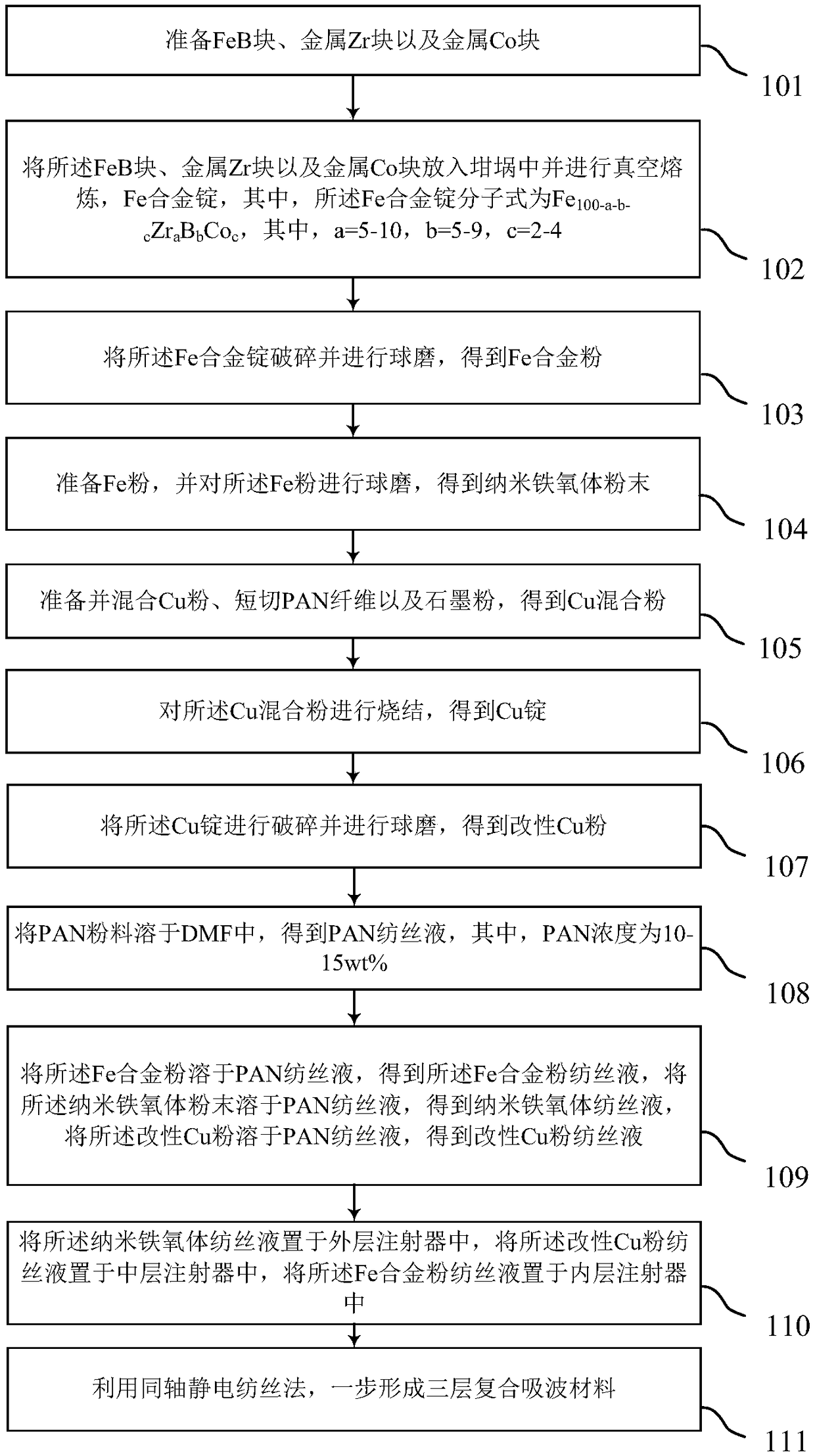

Image

Examples

Embodiment 1

[0031] The one-step method for preparing a three-layer composite absorbing material of the present invention includes the following steps: preparing FeB blocks, metal Zr blocks, and metal Co blocks; putting the FeB blocks, metal Zr blocks and metal Co blocks into a crucible and performing vacuum melting, Obtain Fe alloy ingot, wherein the molecular formula of Fe alloy ingot is Fe 100-a-b-c Zr a B b Co c , Where a=5, b=5, c=2; crush the Fe alloy ingot and ball mill to obtain Fe alloy powder; prepare Fe powder, and ball mill the Fe powder to obtain nano ferrite powder; prepare and mix Cu powder, chopped PAN fiber and graphite powder to obtain Cu mixed powder; sinter the Cu mixed powder to obtain Cu ingot; crush and ball mill the Cu ingot to obtain modified Cu powder; dissolve PAN powder in DMF , Obtain PAN spinning solution, wherein the PAN concentration is 10wt%; dissolve Fe alloy powder in PAN spinning solution to obtain Fe alloy powder spinning solution, and dissolve nano ferri...

Embodiment 2

[0033] The one-step method for preparing a three-layer composite absorbing material of the present invention includes the following steps: preparing FeB blocks, metal Zr blocks, and metal Co blocks; putting the FeB blocks, metal Zr blocks and metal Co blocks into a crucible and performing vacuum melting, Obtain Fe alloy ingot, wherein the molecular formula of Fe alloy ingot is Fe 100-a-b-c Zr a B b Co c , Where a=10, b=9, c=4; crush and ball mill the Fe alloy ingot to obtain Fe alloy powder; prepare Fe powder and ball mill the Fe powder to obtain nano ferrite powder; prepare and mix Cu powder, chopped PAN fiber and graphite powder to obtain Cu mixed powder; sinter the Cu mixed powder to obtain Cu ingot; crush and ball mill the Cu ingot to obtain modified Cu powder; dissolve PAN powder in DMF , Obtain PAN spinning solution, wherein the PAN concentration is 15wt%; dissolve Fe alloy powder in PAN spinning solution to obtain Fe alloy powder spinning solution, and dissolve nano ferri...

Embodiment 3

[0035] The one-step method for preparing a three-layer composite absorbing material of the present invention includes the following steps: preparing FeB blocks, metal Zr blocks, and metal Co blocks; putting the FeB blocks, metal Zr blocks and metal Co blocks into a crucible and performing vacuum melting, Obtain Fe alloy ingot, wherein the molecular formula of Fe alloy ingot is Fe 100-a-b-c Zr a B b Co c , Where a=6, b=6, c=2.5; crush and ball mill the Fe alloy ingot to obtain Fe alloy powder; prepare Fe powder, and ball mill the Fe powder to obtain nano ferrite powder; prepare and mix Cu powder, chopped PAN fiber and graphite powder to obtain Cu mixed powder; sinter the Cu mixed powder to obtain Cu ingot; crush and ball mill the Cu ingot to obtain modified Cu powder; dissolve PAN powder in DMF , Obtain PAN spinning solution, wherein the PAN concentration is 11wt%; dissolve Fe alloy powder in PAN spinning solution to obtain Fe alloy powder spinning solution, and dissolve nano fer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com