An anti-clogging online sampling device for the mother liquor of a paraformaldehyde reaction kettle

A sampling device and trioxymethylene technology, which is applied in the sampling device and other directions, can solve the problem that the sampling pipeline is easy to be blocked and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

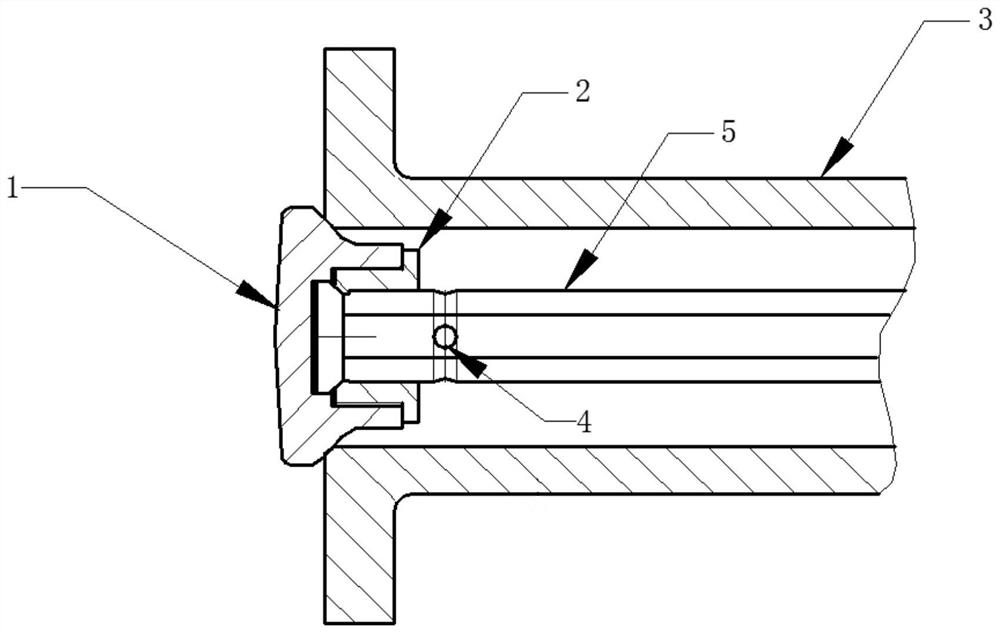

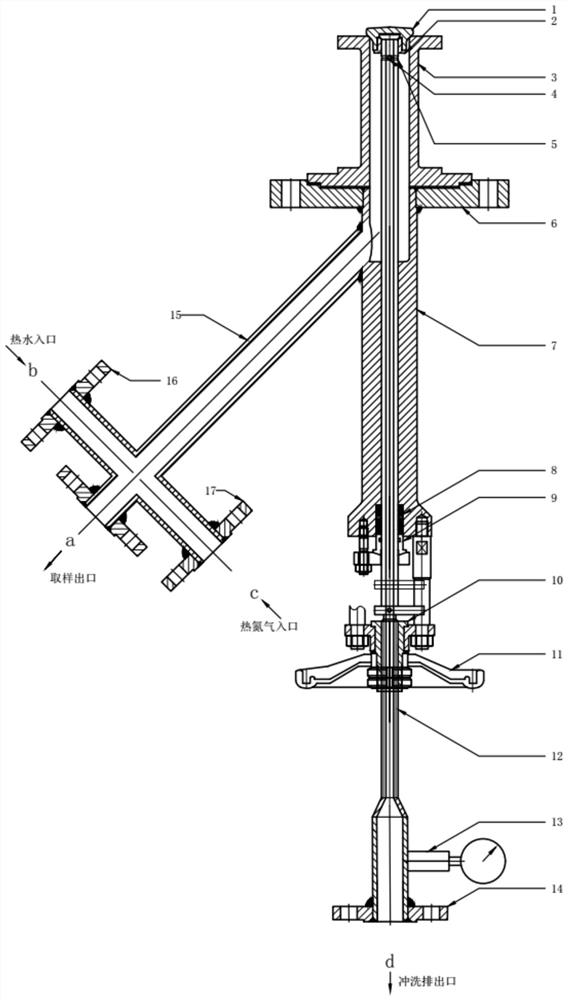

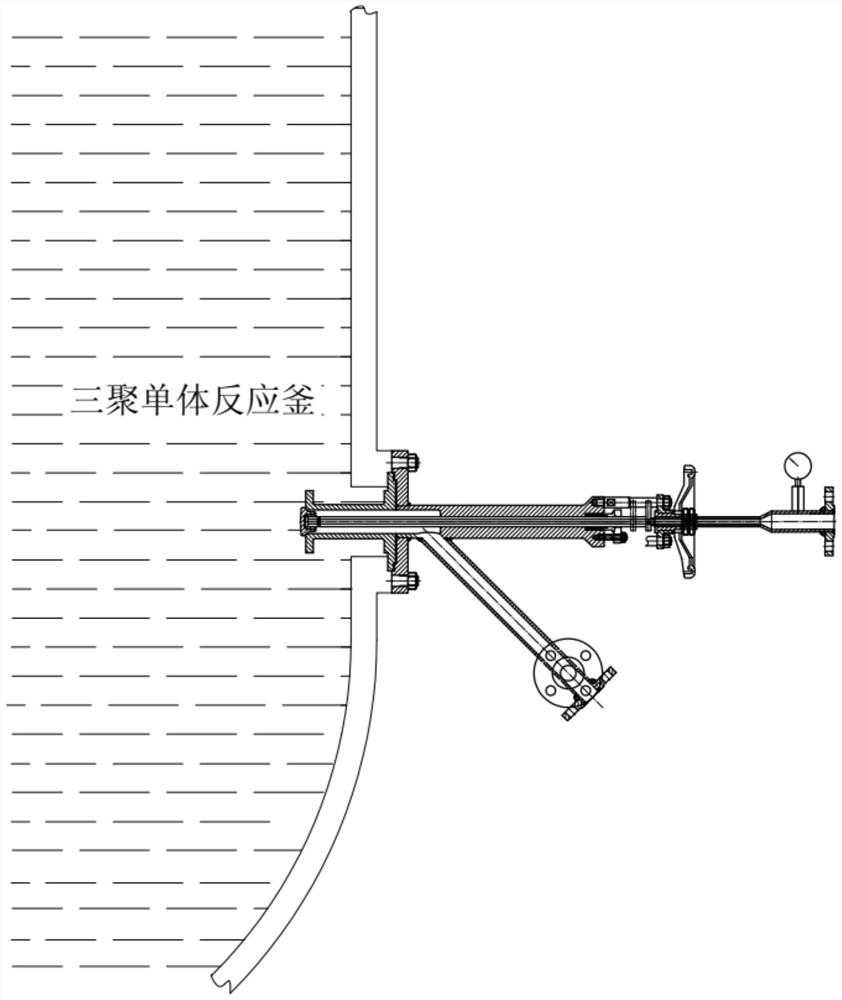

[0058] Such as Figure 1-3 As shown, a paraformaldehyde reaction kettle mother liquor anti-blocking online sampling device, including: sampling sealing plug 1, sampling sealing plug fixing cover 2, sampling distance sleeve 3, flushing hole 4, sampling push rod 5, reaction kettle connection method Lan 6, sampling device body 7, sealing packing 8, packing gland 9, sampling push rod nut 10, sampling push rod hand wheel 11, sampling push rod threaded part 12, temperature instrument 13, flushing outlet flange 14, sampling device Outlet pipe 15, hot water inlet flange 16, hot nitrogen inlet flange 17, sampling outlet flange 18, and liquid-taking cavity 19.

[0059] One end of the sampling device body 7 is connected to the sampling distance sleeve 3 through the connecting flange 6 of the reaction kettle.

[0060] Offer a through hole in the sampling device body 7, the sampling push rod 5 runs through the through hole, and one end of the sampling push rod 5 extends to the outside of ...

Embodiment 2

[0070] A paraformaldehyde reaction kettle mother liquor anti-blocking online sampling device, the same as embodiment 1, the difference is that: the outlet pipe 15 of the sampling device communicates with the part of the liquid sampling cavity 19 located in the sampling device body 7, and the flushing hole 4 Set at a position 13mm from the top of the sampling push rod. The diameter of the flushing hole 4 is 3mm. The number of the flushing holes 4 is four, and they are evenly distributed along the same circumferential direction of the sampling push rod 5 . The diameter of the flushing liquid channel hole is 5mm.

Embodiment 3

[0072] A method for anti-clogging online sampling of a paraformaldehyde reactor mother liquor, comprising the steps of:

[0073] (1) Preheating: First, open the ball valves at the flange 14 of the flushing discharge outlet and the flange 17 of the hot nitrogen gas inlet in sequence, and feed in hot nitrogen gas at 100°C to preheat the sampling device. The hot nitrogen gas passes through the hot nitrogen gas inlet c, and then passes through After the outlet pipe 15 of the sampling device, the liquid sampling cavity 19, the flushing hole 4 and the flushing liquid flow channel hole, it is discharged from the flushing outlet d, and the preheating process lasts for 3 minutes;

[0074] (2) Sampling: open 18 ball valves of the sampling outlet flange, rotate the sampling push rod handwheel 11 and push the sampling push rod 5 into the reaction vessel for sampling, the mother liquor passes through the liquid sampling cavity 19 and the sampling device outlet pipe 15, and then After the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com