Method for predicting permeability of coal under stress loading conditions based on CT scans

A technology of CT scanning and stress loading, applied in the direction of permeability/surface area analysis, using stable tension/pressure to test material strength, measuring devices, etc., to achieve the effect of ensuring accuracy, high accuracy, and overcoming severe distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for predicting coal permeability under stress loading conditions based on CT scanning, comprising the following steps:

[0038] A. Make coal sample specimens, conduct uniaxial compression experiments, and conduct CT scans on coal sample specimens at the same time;

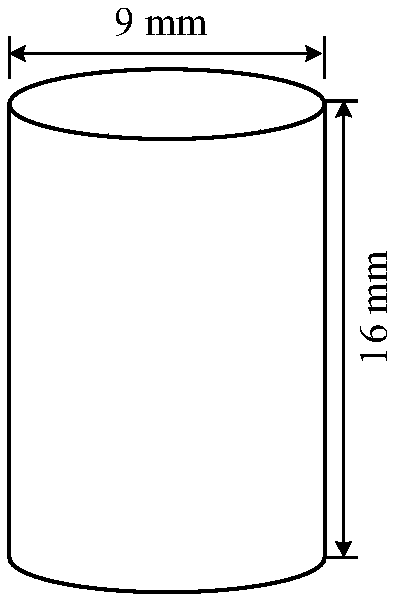

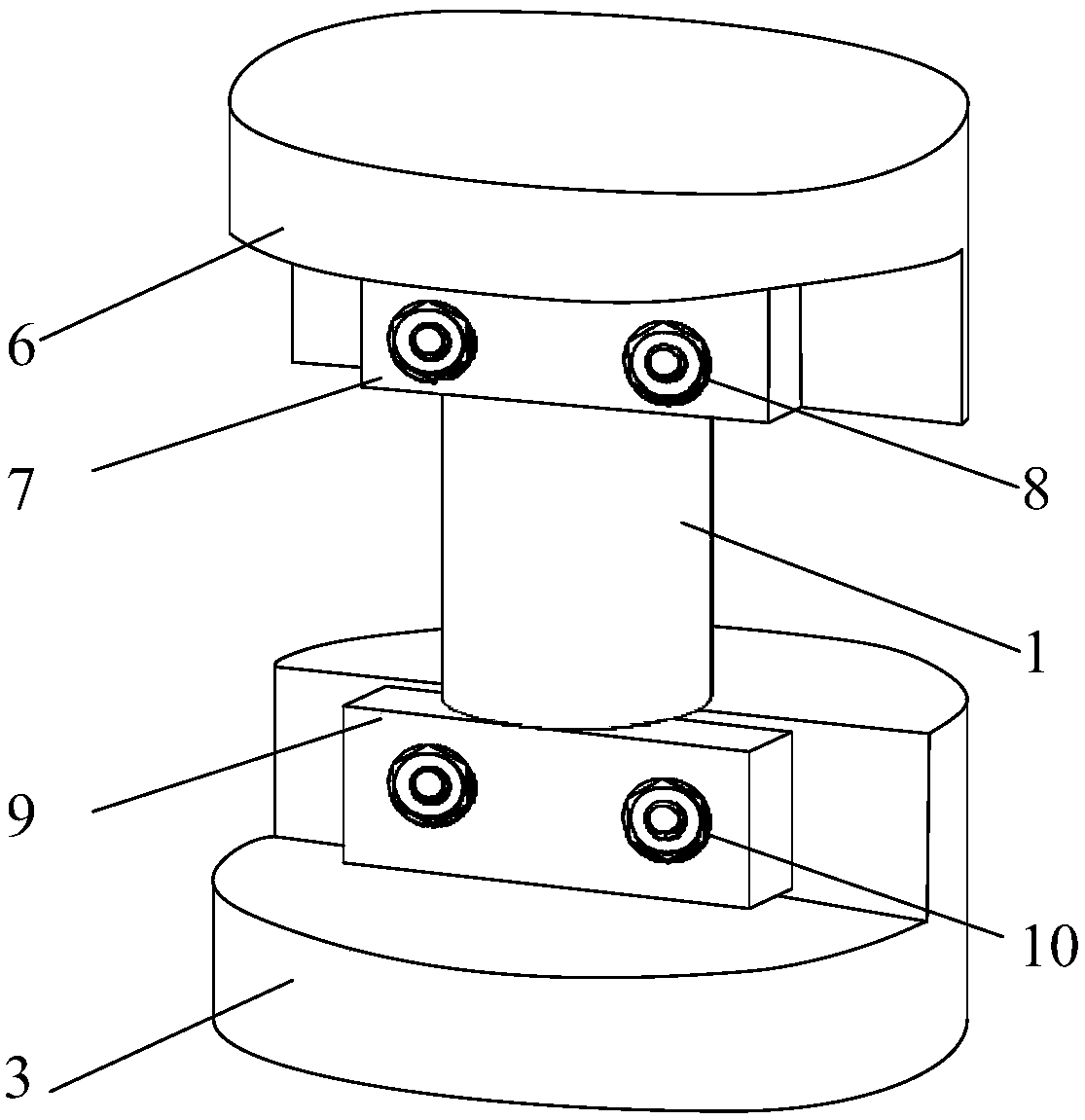

[0039] Wherein, the coal sample is a cylinder, and the uniaxial compression test uses an in-situ tension, compression and temperature control experimental device; Axial compression, the loading speed of the same coal sample is constant.

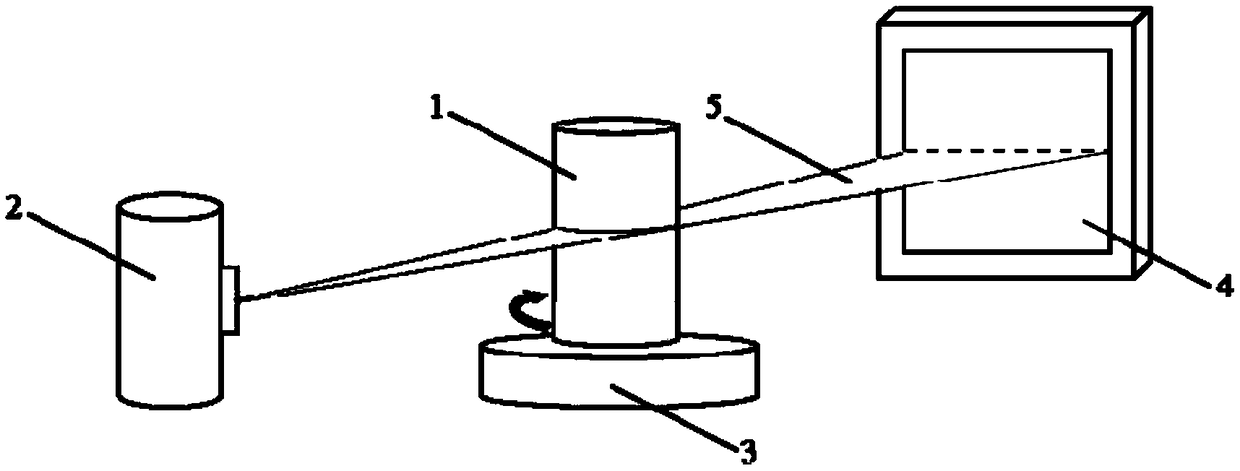

[0040] In this step, the scan voltage, scan power and field of view are first determined according to the X-ray stability, coal sample size, coal sample X-ray attenuation fraction and exposure time before the CT scan; Rotating and scanning at a constant speed, the detector captures the X-rays emitted by the X-ray source and passes through the coal sample, and stores the CT scan image in the form of electrical signals.

[0041] B. Use the DTM digital terrain model...

Embodiment 2

[0051] The implementation steps of the method for predicting coal permeability under CT scanning based on stress loading conditions provided by the present invention include: using a nanoVoxel-3502E scanner and an in-situ tension and compression control experimental device to conduct different tests on multiple groups of coal sample specimens. CT scanning under stress loading conditions to obtain structural CT scanning images of coal samples during compression. The obtained CT scan images are used to establish a three-dimensional numerical model through Simpleware software, so as to convert the CT scan images of the deformed coal body structure into a numerical model with visual features, so as to facilitate the intuitive description of the internal seepage distribution of the coal body. The seepage condition setting of coal body structure is set through HyperMesh software, mainly including air field simulation and water field simulation. Ls-dyna software is used for simulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com