Method for detecting lithium ion battery pack

A technology of lithium-ion battery pack and detection method, which is applied in the direction of measuring electricity, measuring device, measuring electrical variables, etc., can solve the problems of immature batteries, etc., and achieve the effects of improving operation safety, improving stability and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

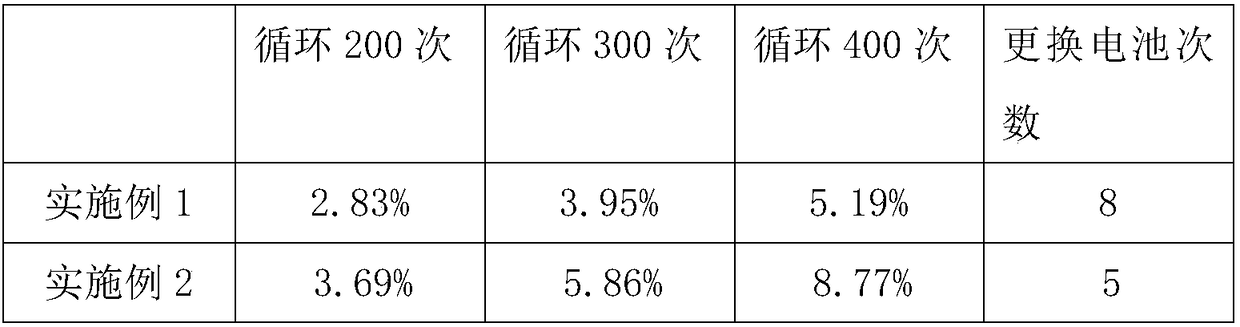

Embodiment 1

[0030] 1) Provide a set of lithium-ion batteries to be formed, pulse charge the battery with a current of 0.05C until the charging cut-off voltage stops; the pulse time is 10min, the interval time is 120s, and the charging cut-off voltage is 4.35V;

[0031] 2) Discharging the battery with a current of 0.2C to the discharge cut-off voltage, the discharge cut-off voltage is 2.8V;

[0032] 3), repeat steps 1-2 3 times;

[0033] 4), static aging for 5 days;

[0034] 5) Pull out the electrolyte solution that is not immersed in the electrodes in the battery case, re-inject new electrolyte solution, and seal it. The new electrolyte solution includes 1.2mol / L lithium hexafluorophosphate and carbonic acid with a volume ratio of 1:2:1 Dimethyl ester, ethyl carbonate, a non-aqueous solvent composed of ethyl methyl carbonate, and 5% by volume of fluorovinylene carbonate;

[0035] 6) Charge the battery with a current of 5C to a cut-off voltage of 4.35V, and then discharge the battery wit...

Embodiment 2

[0041] 1) Provide a set of lithium-ion batteries to be formed, pulse charge the battery with a current of 0.02C until the charging cut-off voltage stops; the pulse time is 0.1min, the interval time is 30s, and the charging cut-off voltage is 4.2V;

[0042] 2), discharge the battery with a current of 0.05C to the discharge cut-off voltage, and the discharge cut-off voltage is 2.7V;

[0043] 3), repeat steps 1-2 0 times;

[0044] 4), static aging for 1 day;

[0045] 5) Pull out the electrolyte solution that is not immersed in the electrodes in the battery case, re-inject new electrolyte solution, and seal it. The new electrolyte solution includes 1.2mol / L lithium hexafluorophosphate and carbonic acid with a volume ratio of 1:2:1 Dimethyl ester, ethyl carbonate, a non-aqueous solvent composed of ethyl methyl carbonate, and 5% by volume of fluorovinylene carbonate;

[0046] 6) Charge the battery with a current of 1C until the charging cut-off voltage is 4.2V, and then discharge ...

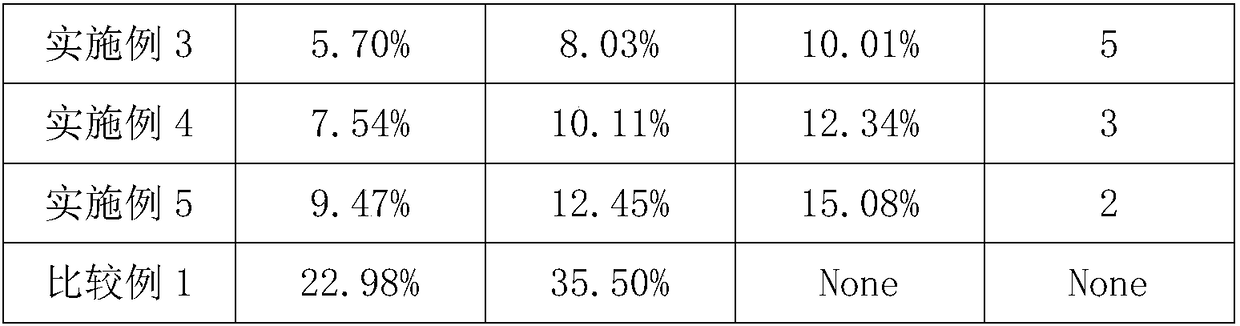

Embodiment 3

[0052] 1) Provide a set of lithium-ion batteries to be formed, pulse charge the battery with a current of 0.03C until the charging cut-off voltage stops; the pulse time is 2min, the interval time is 40s, and the charging cut-off voltage is 4.3V;

[0053] 2) Discharging the battery with a current of 0.1C to the discharge cut-off voltage, the discharge cut-off voltage is 2.75V;

[0054] 3), repeat steps 1-2 twice;

[0055] 4), static aging for 3 days;

[0056] 5) Pull out the electrolyte solution that is not immersed in the electrodes in the battery case, re-inject new electrolyte solution, and seal it. The new electrolyte solution includes 1.2mol / L lithium hexafluorophosphate and carbonic acid with a volume ratio of 1:2:1 Dimethyl ester, ethyl carbonate, a non-aqueous solvent composed of ethyl methyl carbonate, and 5% by volume of fluorovinylene carbonate;

[0057] 6) Charge the battery with a current of 3C until the charging cut-off voltage is 4.25V, and then discharge the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com