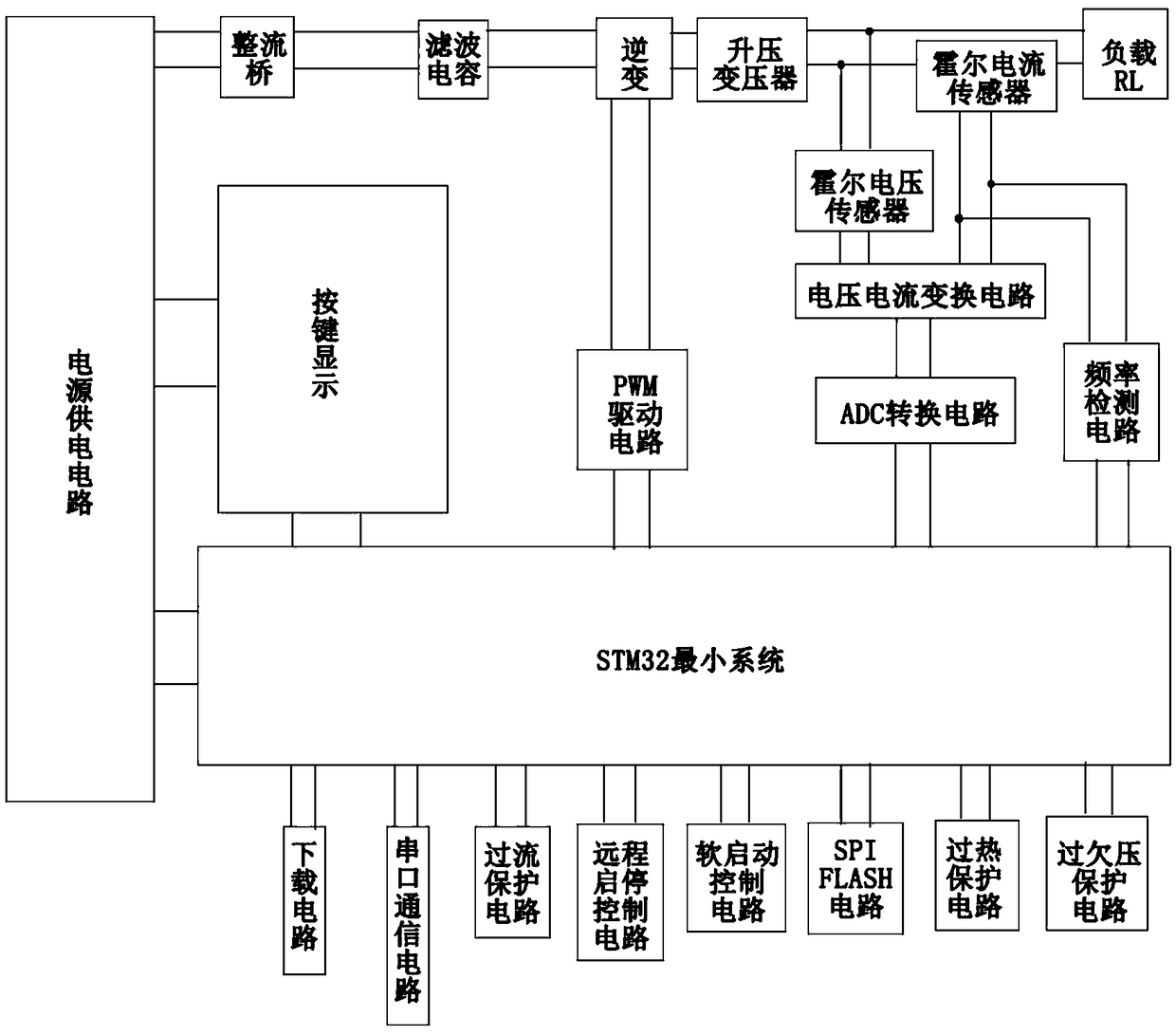

A high-voltage plasma discharge power supply device based on STM32 adjustable voltage

A discharge power supply and plasma technology, applied in the field of ion discharge power supply equipment, can solve the problems of poor voltage regulation accuracy, electromagnetic interference, poor adaptability, etc., and achieve the effect of improving production efficiency and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

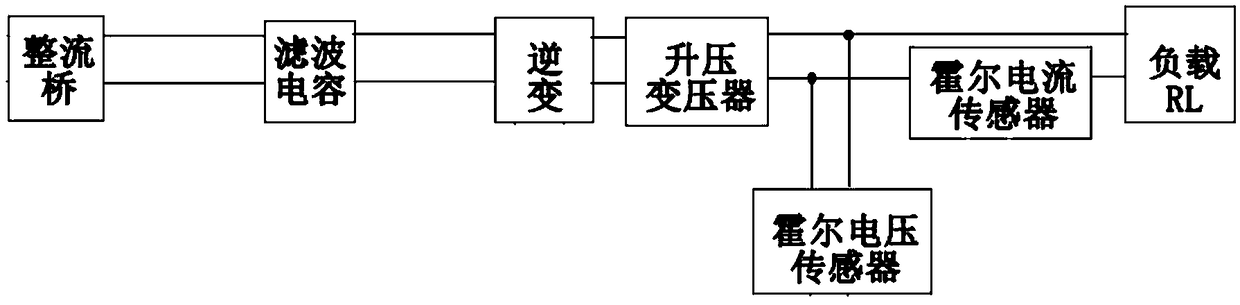

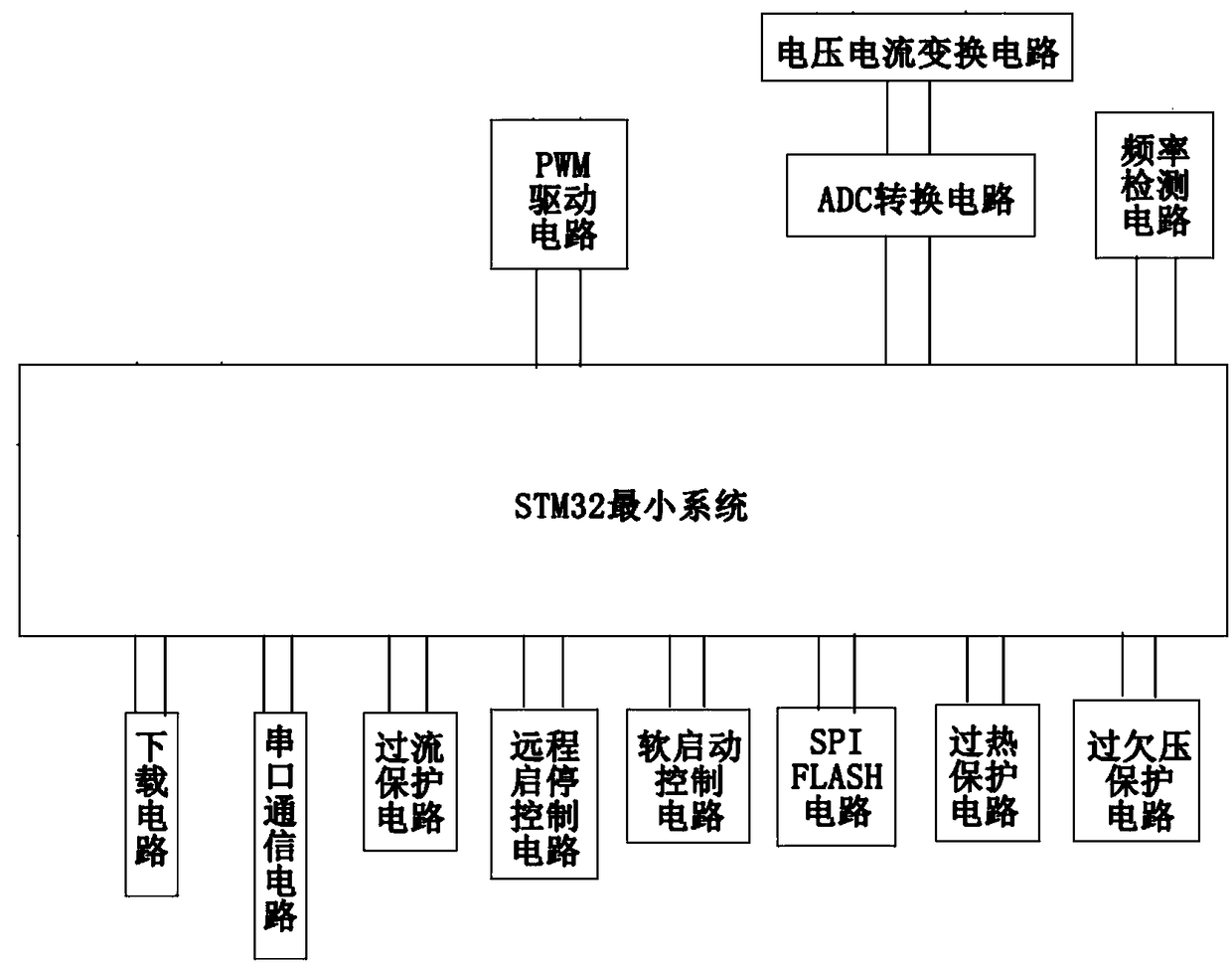

Method used

Image

Examples

Embodiment

[0042] When the device is powered on, the LCD display will display various parameters of the current circuit, and the indicator light will also display the status of the current device; press the start button, the control circuit will output a PWM signal, and the MOS tube will be controlled by the PWM drive circuit. , so as to change the direct current into a pulsed square wave and realize the inverter function. The pulsed square wave is converted into the required high-voltage alternating current through the step-up transformer to supply the load. Press the stop button to stop outputting the PWM signal at any time, so that the main circuit stops working; During the working process of the equipment, the required working parameters can be selected at any time through the host computer or LCD display, and the equipment adjusts the frequency or duty cycle through PID control to achieve the purpose of changing and stabilizing the parameters; during the working process of the equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com